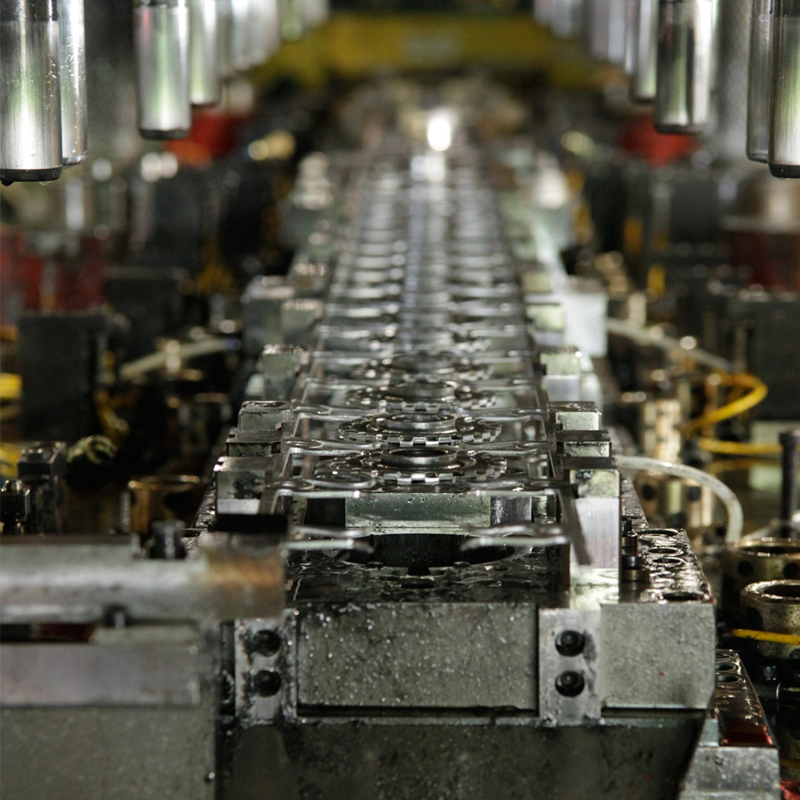

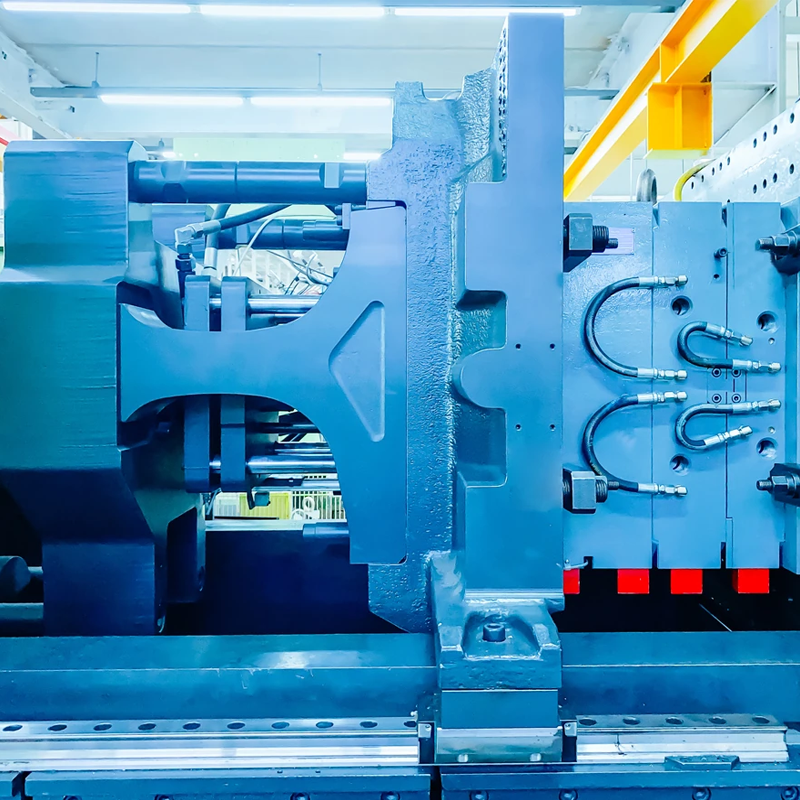

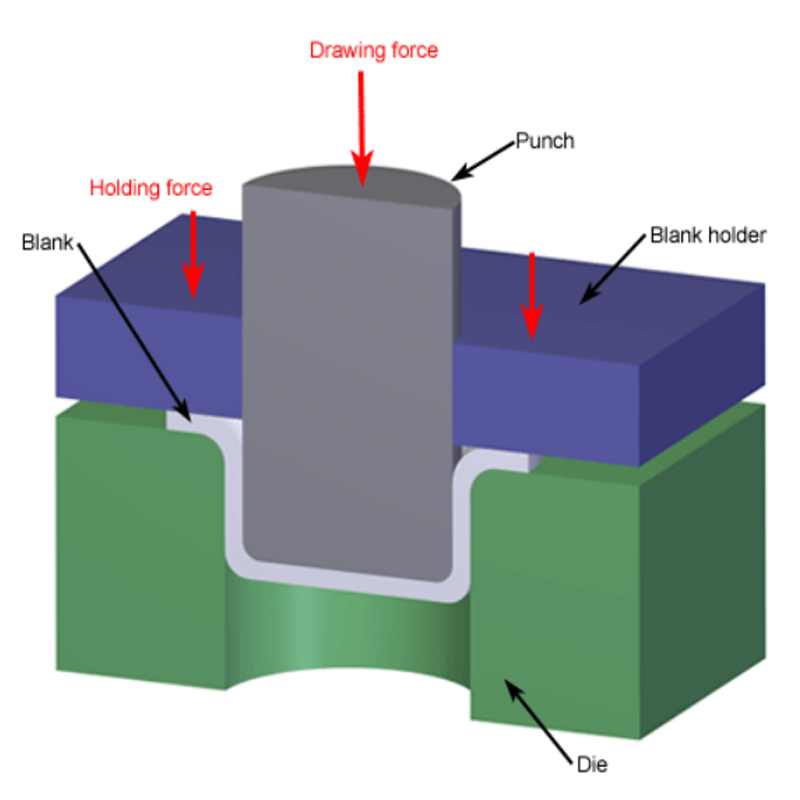

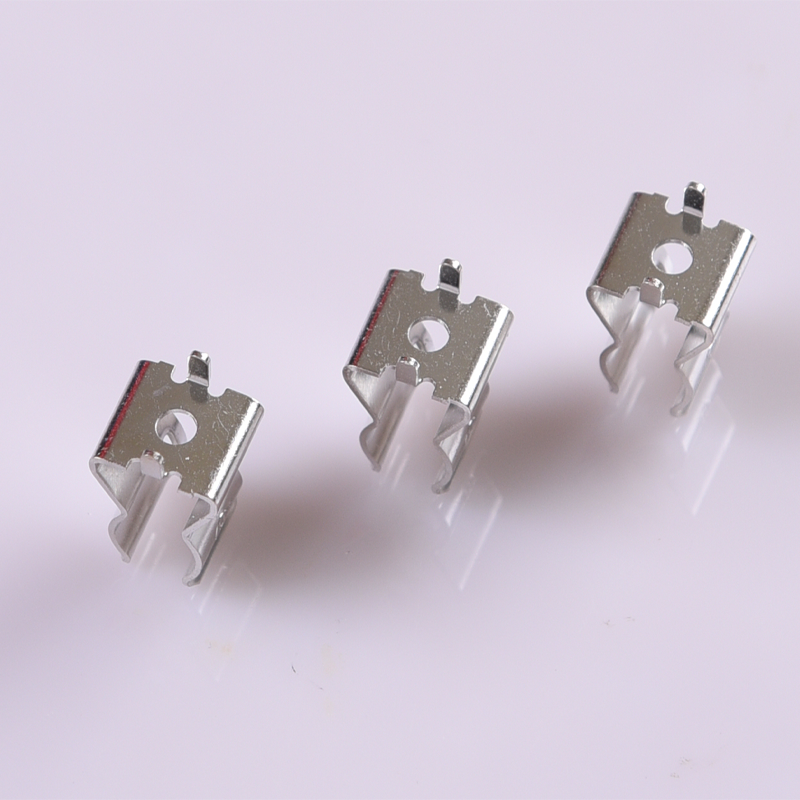

In the world of modern manufacturing, few tools are as essential as dies. These specialized tools are pivotal in shaping raw materials—such as metal, plastic, and composites—into complex, precise parts used across a wide array of industries. Whether you’re producing automotive components, consumer electronics, or industrial equipment, dies play a central role in ensuring consistency, […]