Aperçu

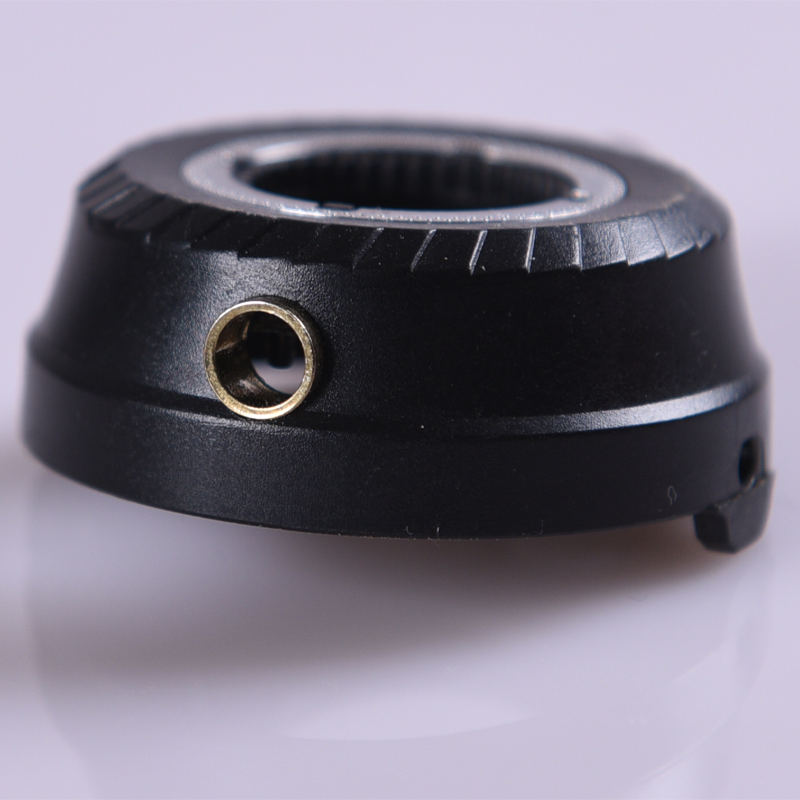

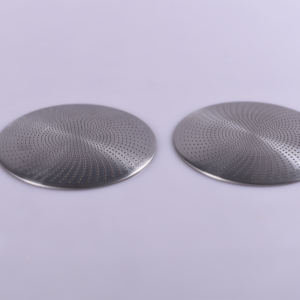

Le boîtier du casque est un composant essentiel d'un casque audio. Il est conçu pour loger et protéger les pièces internes tout en garantissant durabilité et confort. Fabriqué à partir de matériaux de haute qualité, ce boîtier offre une enveloppe extérieure sécurisée pour les éléments électroniques et acoustiques du casque. Il est conçu pour un assemblage facile et des performances durables, ce qui le rend idéal pour une utilisation dans les centres d'appels professionnels, les bureaux et les appareils audio personnels. Le boîtier du casque assure à la fois une protection fonctionnelle et un design élégant et ergonomique pour une expérience utilisateur améliorée.

Le processus de production de nos pièces embouties en métal :

-

Reçu de Commande et Révision du Dessin

Recevoir et examiner les commandes des clients, y compris les dessins techniques aux formats tels que DXF, IGS, STEP ou PDF.

-

Confirmation de conception

Confirmer les détails du design avec le client pour garantir leur exactitude avant le début de la production.

-

Préparation du Matériel

Sélectionnez et préparez les feuilles de métal conformément aux spécifications requises.

-

Coupe de Précision

Utilisez la découpe laser et le cisaillage CNC pour couper des feuilles de métal aux dimensions précises.

-

Formation et Formage

Effectuer le pliage, le poinçonnage et le estampage pour obtenir les formes et caractéristiques souhaitées.

-

Soudage et Rivetage

Assembler des composants métalliques en utilisant des techniques de soudage avancées et le rivetage.

-

Traitement de Surface

Appliquer les traitements de surface nécessaires, y compris le placage et la pulvérisation, pour améliorer la durabilité et l'apparence.

-

Assemblage et Contrôle Qualité

Assemblez les composants et effectuez des contrôles de qualité rigoureux pour garantir le respect des spécifications.

-

Emballage et Expédition

Emballer les pièces finies de manière sécurisée et gérer la logistique pour une livraison ponctuelle au client.

-

Support Après-Vente

Fournir un support continu et résoudre tout problème après livraison afin de garantir la satisfaction du client.

Contrôle de Qualité

La qualité est notre priorité absolue. Dès le début de chaque projet, nous effectuons une étude de faisabilité des pièces métalliques afin de garantir leur fabricabilité. Nous réalisons également une étude de cadence lors du premier cycle de production afin de valider la qualité avant de passer à la fabrication à grande échelle. Cela permet à nos équipes de gestion de la qualité et de la production de suivre de près les contrôles et d'assurer le bon déroulement des opérations. Une fois les tests effectués avec succès, nous procédons à la production du premier lot de pièces métalliques conformes.

Notre système de gestion de la qualité repose sur une technologie et des contrôles avancés, des initiatives d'amélioration continue, ainsi que sur un laboratoire et une équipe qualité de pointe. Dans toute notre usine de production, nous utilisons des systèmes de vision par caméra en ligne et hors ligne, ainsi que des capteurs, personnalisés pour chaque programme de production. Notre technologie de vision s'intègre à nos presses à emboutir pour inspecter et vérifier méticuleusement les caractéristiques et les dimensions des pièces grâce à l'imagerie automatisée. Ce processus rigoureux de contrôle qualité garantit que chaque pièce métallique produite répond à nos normes élevées, assurant une qualité de 100 % et zéro défaut.

Pourquoi Nous Choisir ?

-

Large choix et livraison rapide

Nous proposons une gamme d'options variée et assurons une livraison rapide.

-

Vaste réseau de vente

Notre réseau de vente bien établi assure une couverture de marché complète.

-

Équipements et Techniques de Production Avancés

Nous utilisons des équipements de pointe et des méthodes de production innovantes.

-

Prix compétitifs et service exceptionnel

Profitez de prix compétitifs associés à notre engagement pour un excellent service client.

-

Créations personnalisées disponibles

Nous nous adaptons à diverses demandes de conception pour répondre aux spécifications du client.

-

Contrôles de qualité rigoureux

Nos équipements de test de pointe garantissent une inspection à 100 % des dimensions critiques pour une qualité supérieure.