Ces clips de fixation métalliques à vis sont des solutions d'attache durables et polyvalentes, idéales pour un large éventail d'applications. Fabriqués en métal de haute qualité, ils offrent une prise sûre et fiable, garantissant des performances durables. Les vis sont faciles à serrer, offrant une adhérence ferme pour les projets légers comme les plus lourds. Parfaits pour une utilisation dans la construction, l'automobile et le bricolage, ces clips offrent résistance et stabilité dans divers environnements. Fabriqués avec précision dans une usine de confiance, chaque clip est soumis à un contrôle qualité rigoureux pour répondre aux normes de durabilité et de sécurité de l'industrie.

Informations de base

Traitement de surface : Électroplacage

Processus de Formation : Pièces en Emboutissage Métallique

Options de Finition de Surface : Placage Nickel, Placage Sn, Placage Étain, Placage Zinc

Disponibilité de l'échantillon : Disponible

Tolérance : ±0,001 mm

Taille : Personnalisable selon les besoins

Application : Industriel, Mobilier, Automobile, Moto, etc.

Approche de fabrication : Emboutissage métallique, Découpe, Poinçonnage, Pliage, Soudage

Emballage de Transport : Sac OPP, Boîte ou Personnalisé

Spécification : Personnalisée

Origine : Xiamen, Chine

Pourquoi Nous Choisir ?

-

Expertise dans la production de pièces OEM

Description : Spécialisé dans la production de pièces OEM, y compris les composants emboutis, usinés, étirés profonds et formés en tôle. Nous proposons également une gamme d'options de finition pour répondre à des exigences variées.

-

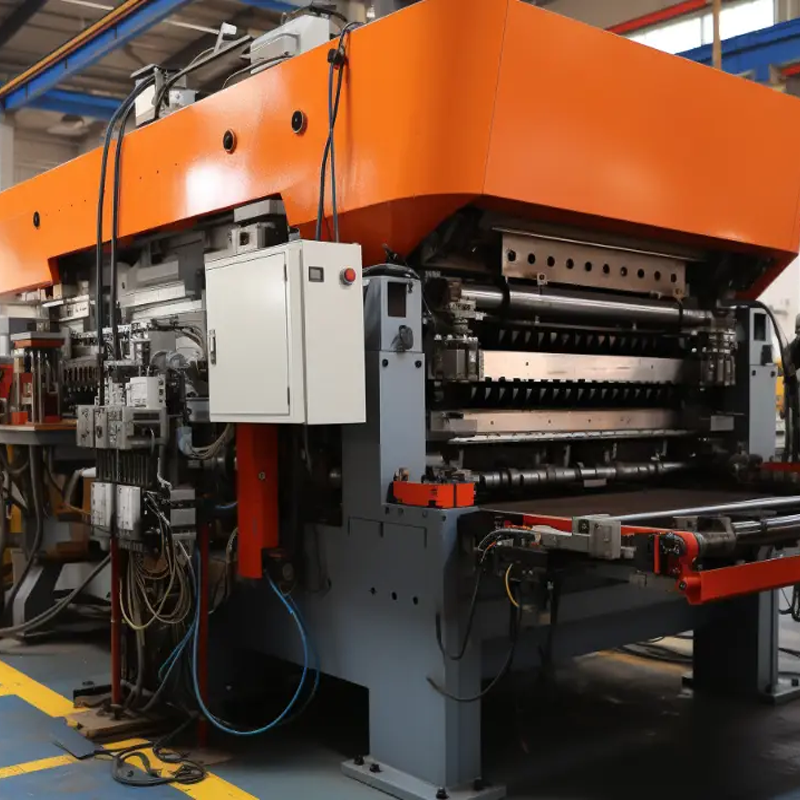

Machinerie et Équipements Avancés

Description : Équipé d'une gamme complète de machines pour le poinçonnage, le soudage, la CNC, le fraisage et le meulage. Notre installation utilise des équipements fiables et des technologies avancées pour garantir une production de haute qualité.

-

Main-d'œuvre qualifiée et expertise technique

Description : Notre équipe se compose de techniciens expérimentés dédiés au développement technique, d'ouvriers qualifiés, d'ingénieurs professionnels et d'un centre de R&D solide. Nous disposons également d'une équipe exceptionnelle dédiée au commerce international, tous engagés à soutenir nos clients avec enthousiasme et expertise.

-

Personnalisation Basée sur le Design

Nous offrons une personnalisation étendue en fonction de vos exigences de conception. Nos ingénieurs expérimentés collaborent étroitement avec vous pour développer des moules qui correspondent précisément à vos spécifications, garantissant ainsi des performances et une fonctionnalité optimales.

-

Personnalisation Basée sur des Échantillons

Nous offrons une personnalisation basée sur des échantillons soumis. Ce processus nous permet de reproduire et d'améliorer des designs existants, garantissant que le produit final correspond parfaitement à vos attentes.

Documentation de qualité

- Certification ISO 9001:2015

- Certification IATF 16949

- Inspection du Premier Article (IPA)

- Rapport PPAP (Processus d'Approbation des Pièces de Production)

- Fiches Techniques des Matériaux (FTM)

- Rapport d'Inspection CMM

- Rapport SPC (Contrôle Statistique des Processus)

- Certificats de Matériau

- Rapport d'Inspection Dimensionnelle (CMM)

- Retour d'information DFM