Aperçu :

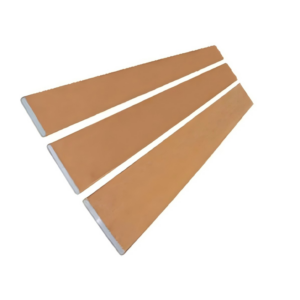

Les jeux de barres, également appelés barres omnibus, sont des composants essentiels des systèmes de distribution d'énergie, offrant une plus grande flexibilité et une facilité d'installation par rapport aux méthodes de câblage traditionnelles. Généralement fabriqués en cuivre, en laiton ou en aluminium, les jeux de barres conduisent efficacement l'électricité tout en assurant la mise à la terre. Dans notre usine, nous sommes spécialisés dans la conception et la fabrication de jeux de barres de haute qualité, adaptés aux besoins spécifiques de diverses industries. En tant que fournisseur leader de pièces et d'assemblages en métal estampé, nous nous engageons à fournir des jeux de barres fiables et performants pour les applications exigeantes. Avec la demande croissante de véhicules électriques, nous avons renforcé nos capacités à produire des jeux de barres personnalisés conçus pour transmettre efficacement l'énergie dans les systèmes de véhicules électriques. Nos services complets et intégrés garantissent des solutions de bout en bout, de la conception à la livraison, répondant à vos spécifications exactes pour des performances et une sécurité optimales.

Détails :

| Attribut | Détails |

| Type de traitement | Façonnage du métal |

| Matériau | Cuivre |

| Moule | Moules Simples à Processus Unique |

| Traitement de Surface | Polissage |

| Découpage Fin | Ouvrir |

| Processus | Processus de Formation |

| Tolérances | ±0.01 mm |

| Personnalisation | Disponible |

| Terminer | Nu, Étamage, Nickelage |

| Isolation | Gaine thermorétractable en PE, PVC, Poudre époxy |

| Taille | Personnalisé |

| Colis de transport | Sac en polypropylène + Caisse en bois |

| Spécification | Personnalisé |

| Marque déposée | OEM |

| Origine | Xiamen, Chine |

| Capacité de Production | 10 000 pièces/jour |

Options de traitement de surface :

Brossage : Un procédé qui améliore la texture de surface et procure un fini mat, offrant une esthétique améliorée et une meilleure résistance à la corrosion.

Polissage : Permet d'obtenir une surface lisse et brillante, améliorant l'aspect visuel et offrant une protection supplémentaire contre l'oxydation.

Anodisation : Un procédé électrochimique qui forme une couche d'oxyde protectrice sur les surfaces métalliques, améliorant la résistance à la corrosion et à l'usure.

Thermolaquage : Un procédé de finition à sec qui applique une couche protectrice et décorative, offrant une résistance supérieure aux intempéries, aux rayures et aux produits chimiques.

– Placage : L'application d'une fine couche métallique (telle que l'or, le nickel ou le chrome) pour améliorer l'apparence, la résistance à la corrosion et la conductivité.

Sablage : Procédé de nettoyage et de préparation de surface utilisant des matériaux abrasifs pour créer une surface rugueuse, améliorant ainsi l'adhérence des revêtements ou des finitions.

Processus d'Assurance Qualité pour les Barres Conductrices Électriques en Laiton :

Dans notre usine, la qualité est primordiale. Chaque cycle de production commence par une étude de faisabilité approfondie et une étude de cadence pour garantir la fabricabilité et la qualité avant le lancement de la production à grande échelle. Cette approche permet à nos équipes qualité et production de mettre en place des contrôles stricts, assurant le bon déroulement des opérations. Une fois que les tests initiaux confirment la conformité aux spécifications, la production se poursuit et le premier lot de barres omnibus électriques en laiton est fabriqué.

Notre système de gestion de la qualité intègre des technologies d'inspection avancées, des processus d'amélioration continue et une équipe d'assurance qualité compétente. Grâce à des systèmes de vision par caméra et des capteurs de pointe intégrés à nos machines d'emboutissage, nous effectuons des inspections en temps réel pour garantir que toutes les pièces respectent des spécifications précises. Ce processus rigoureux garantit que chaque barre omnibus électrique en laiton répond à nos normes élevées, avec une qualité de 100 % et zéro défaut.

Pourquoi Nous Choisir ?

- Prix compétitifs : Nous proposons des prix très compétitifs en direct de notre usine, garantissant des solutions économiques pour nos clients.

- Assurance Qualité : Notre processus complet de contrôle qualité comprend des inspections du premier article, des vérifications en cours de production et des inspections finales du produit afin de garantir une qualité supérieure.

- Service Exceptionnel : Notre équipe dédiée est spécialisée dans l'assistance avant-vente, le contrôle qualité, la logistique et le service après-vente afin de vous garantir une expérience sans faille.

- Livraison rapide : Grâce à une gamme de tailles et de couleurs standard disponibles en stock, nous pouvons traiter les commandes rapidement et efficacement pour respecter vos délais.