Description :

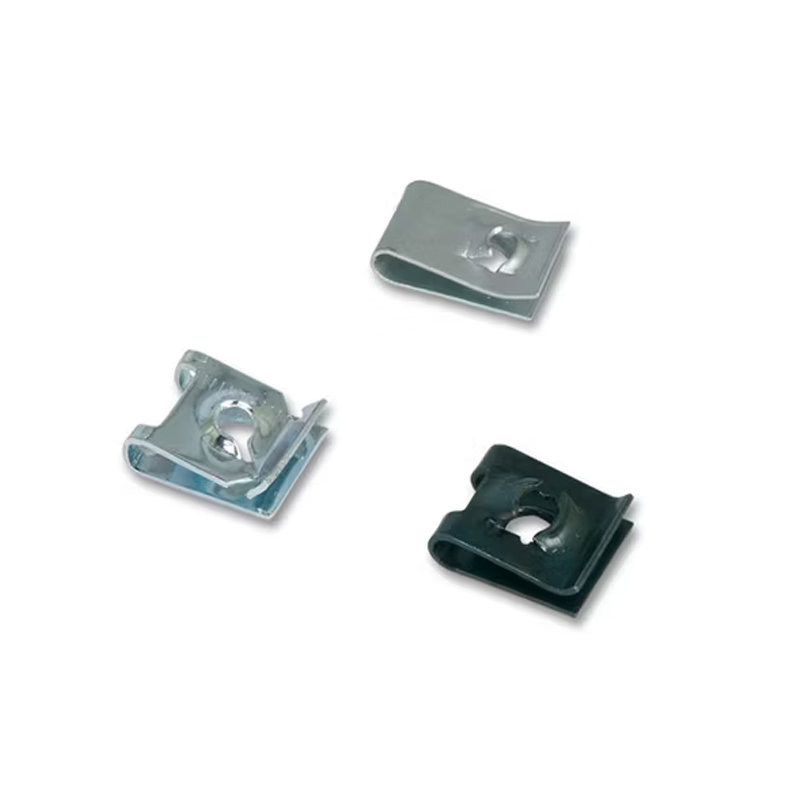

Les clips d'estampage en acier inoxydable avec passivation acide sont des composants de haute précision conçus pour la durabilité et la résistance à la corrosion. Le processus de passivation acide crée une couche protectrice qui améliore la longévité, les rendant idéaux pour les applications exigeantes dans les secteurs automobile, électrique, aérospatial et industriel.

Ces clips offrent une résistance exceptionnelle et sont personnalisables en taille, dimensions et finitions de surface, y compris la galvanisation à chaud, le nickelage et le thermolaquage. Contactez-nous pour des clips de fixation métalliques estampés avec précision et adaptés à vos besoins.

Caractéristiques :

| Attribut | Détails |

| Matériau | Acier inoxydable |

| Moule | Matrices progressives à étapes multiples |

| Traitement de Surface | Acier inoxydable – Passivation acide |

| Processus | Processus de Formation |

| Industrie | Pièces d'emboutissage métallique |

| Tolérances | 0,01 mm |

| Personnalisation | Chaleureusement accueilli |

| Date de livraison | 15 jours |

| Lieu d'origine | Xiamen, Chine |

| Colis de transport | Personnalisé |

| Spécification | Personnalisé |

| Marque déposée | OEM |

| Taille | Personnalisé |

Processus de production :

- Choix des matériaux : De l'acier inoxydable de qualité supérieure est soigneusement sélectionné pour sa résistance, sa durabilité et sa résistance supérieure à la corrosion afin de répondre aux exigences spécifiques du produit final.

- Estampage du métal : La tôle d'acier inoxydable est traitée par des matrices d'estampage progressif de haute précision, assurant une découpe, un formage et une mise en forme constants des clips avec une précision exceptionnelle.

- Opérations de formage : Après l'estampage, les clips subissent des opérations de formage supplémentaires pour obtenir une géométrie et des dimensions précises, garantissant ainsi un ajustement et un fonctionnement corrects dans leurs applications finales.

- Traitement de passivation acide : Les clips sont ensuite soumis à un processus de passivation acide, qui élimine le fer libre de la surface, formant une couche d'oxyde protectrice. Ce traitement améliore significativement la résistance à la corrosion et protège contre la rouille et l'oxydation.

- Contrôle et assurance qualité : Chaque clip est minutieusement inspecté pour vérifier la précision dimensionnelle, la finition de surface et l'intégrité fonctionnelle, garantissant ainsi qu'il répond à des normes strictes de performance et de durabilité.

- Emballage et Expédition : Les clips terminés sont soigneusement emballés afin d'éviter tout dommage pendant le transport. Des options d'emballage personnalisées sont disponibles en fonction des besoins spécifiques du client, garantissant une livraison sûre et fiable.

Options de traitement de surface :

- Dorure à l'or : Une fine couche d'or qui améliore la résistance à la corrosion, la conductivité électrique et l'apparence, idéale pour l'électronique haut de gamme.

- Placage argent : Le revêtement argent améliore la conductivité électrique et la résistance à la corrosion. Il est couramment utilisé dans les applications électroniques et automobiles.

- Nickelage : Offre une excellente protection contre la corrosion et l'usure, idéal pour les environnements difficiles et une durabilité accrue.

- Tin Plating: Offers corrosion resistance, solderability, and improved electrical conductivity, widely used in electronics for reliable performance.

Aperçu de l'usine :

Notre site est équipé d'un ensemble complet de technologies de fabrication avancées conçues pour offrir une qualité et une précision exceptionnelles. Nous exploitons 25 presses poinçonneuses haute performance, allant de 25 à 300 tonnes, ainsi que des machines d'électroérosion à fil de précision, des systèmes de meulage et de polissage, des équipements de soudage et des unités de nettoyage par ultrasons. Ces capacités nous permettent de produire efficacement des composants métalliques de haute précision.

En complément de nos activités principales d'emboutissage, nous proposons une gamme complète de services de traitement de surface métallique pour améliorer la performance, la durabilité et l'esthétique de nos produits. Nos options de placage incluent la galvanoplastie, la zinguerie, le nickelage, le chromage et l'anodisation. Grâce à des équipements de traitement de surface à la pointe de la technologie, nous garantissons des finitions uniformes et de haute qualité qui offrent une excellente résistance à la corrosion et répondent aux normes industrielles les plus strictes.

En intégrant des lignes de production automatisées, des technologies mécaniques de pointe et des processus de contrôle qualité rigoureux, nous garantissons que chaque pièce de découpe et emboutissage que nous produisons respecte les normes les plus élevées de précision, de fonctionnalité et de fiabilité.