Aperçu :

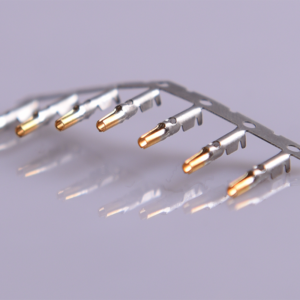

Les connecteurs électriques pour équipements à batterie, également appelés cosses à sertir et connecteurs de fils à sertir, jouent un rôle essentiel dans la liaison des fils et des câbles aux composants d'un système électrique. Ces connecteurs sont indispensables au bon fonctionnement des systèmes alimentés par batterie dans de nombreuses applications, notamment les véhicules, les appareils électroménagers, les panneaux de contrôle et d'autres installations électriques.

Des connexions fiables sont primordiales pour garantir la sécurité et l'efficacité des équipements alimentés par batterie. Une connexion faible ou défectueuse dans le système électrique peut entraîner des problèmes de performance, des fusibles grillés ou une défaillance complète du système.

Avec nos connecteurs électriques de haute qualité, vous pouvez obtenir des connexions durables et fiables pour votre équipement de batterie. En tant que fournisseur de premier plan de pièces métalliques estampées avec précision et d’assemblages, nous soutenons divers secteurs avec des solutions conçues pour répondre aux normes les plus élevées en matière de performance et de fiabilité.

Détails :

| Catégorie | Détails |

| Avantages | Résistance à haute température |

| Processus de Production | Estampage Métallique |

| Forme | Personnalisé |

| Certification | ISO 9001, IATF 16949 |

| Marque | OEM |

| Matériel Disponible | Cuivre, Acier inoxydable, Acier au carbone, Aluminium, etc. |

| Utilisation | Automobile, Agriculture, Mobilier, Machinerie |

| Capacités de presse | 16 tonnes – 300 tonnes |

| Capacité d'estampage | Emboutissage, Façonnage du Métal |

| Matrice d'emboutissage | Fabrication de matrices en interne |

| Échantillons | Disponible gratuitement |

| Service | OEM |

| Format de fichier | CAO, SolidWorks, PDF, etc. |

| Colis de transport | Conformément à vos demandes |

| Marque déposée | OEM |

| Origine | Xiamen |

Processus de production :

- Recherche et Ingénierie de la Qualité : Phase initiale impliquant une analyse détaillée et une conception visant à répondre aux spécifications fonctionnelles et qualitatives.

- Développement d'outillage : Fabrication de précision de moules et matrices pour atteindre des normes rigoureuses en production de masse.

- Approbation des échantillons : Production de prototypes pour les tests et la validation afin de garantir que toutes les spécifications sont respectées avant de passer à l'échelle.

- Production de masse : Fabrication à grande échelle utilisant des équipements avancés pour garantir la cohérence et l'efficacité.

- Inspection de Contrôle Qualité : Évaluation complète à chaque étape pour garantir que tous les produits respectent des normes strictes de qualité et de performance.

- Emballage : Un emballage sécurisé et efficace, conçu pour protéger les produits pendant le transport et la livraison.

Traitements de Surface pour Connecteurs Électriques :

- Placage : Une couche de métal est appliquée sur la surface du connecteur pour améliorer la conductivité, la résistance à la corrosion et la durabilité. Les placages courants incluent l'or, l'étain ou le nickel.

- Revêtement en poudre : Un revêtement durable et non toxique appliqué sur les connecteurs pour améliorer la résistance à l'usure, aux intempéries et à l'exposition aux produits chimiques, tout en offrant une finition lisse et esthétique.

- Anodisation : Un processus qui augmente l'épaisseur de la couche d'oxyde naturelle sur l'aluminium, améliorant ainsi sa résistance à la corrosion et offrant une finition durable et non corrosive.

- Peinture : Revêtements de peinture protecteurs et décoratifs offrant une résistance aux éléments environnementaux et améliorant l'apparence des connecteurs.

- Électrophorèse : Une méthode de revêtement qui utilise un champ électrique pour déposer une couche uniforme de peinture sur les connecteurs, offrant une excellente protection contre la corrosion et l'usure.

- Polissage : Un processus de finition qui lisse la surface du connecteur, améliorant à la fois son attrait esthétique et ses performances électriques en réduisant la résistance.

À propos de nous :