Aperçu :

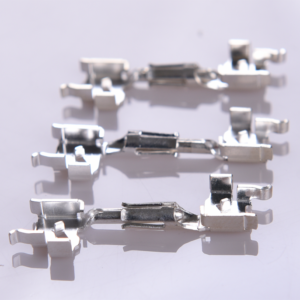

Les contacts électriques en cuivre estampés sont des composants de précision fabriqués grâce au processus d'estampage des métaux. Principalement conçus en cuivre pour ses excellentes propriétés de conductivité et de durabilité, ces contacts garantissent des performances fiables dans les applications électriques. Nous proposons également d'autres matériaux tels que le laiton, l'acier inoxydable et le bronze phosphoreux pour répondre à des besoins spécifiques.

Nos services de personnalisation permettent des conceptions sur mesure adaptées à vos spécifications exactes. Pour des contacts électriques de haute qualité et fiables, contactez-nous dès aujourd'hui pour plus d'informations ou pour un devis.

Caractéristiques :

| Attribut | Détails |

| Lieu d'origine | Xiamen, Chine |

| Nom de la marque | OEM |

| Épaisseur | 0.15mm |

| Tolérance | +/- 0.02 |

| Processus | Estampage de Métal |

| Moule | Conception Personnalisée |

| Test | Essai de Traction |

| Propriété | Bonne connexion |

Processus de production :

-

Conception et Prototypage

La conception initiale et le prototypage des contacts électriques en cuivre sont développés pour garantir la précision et la fonctionnalité.

-

Laser Cutting

Laser cutting is employed for precise, high-quality cutting of materials to the required shapes and sizes.

-

Inspection

Une inspection qualité rigoureuse est effectuée pour vérifier la précision dimensionnelle et la qualité des matériaux avant de passer aux étapes suivantes.

-

Broyage

Le meulage est effectué pour obtenir des surfaces lisses et des tolérances précises pour les contacts.

-

Assemblage

Les composants sont assemblés avec une attention minutieuse à l'alignement et à l'intégrité des connexions, garantissant une fonctionnalité optimale.

-

Estampage Progressif

L'emboutissage progressif est utilisé pour former et façonner les contacts en cuivre en plusieurs étapes, produisant des pièces volumineuses et uniformes.

-

Traitement Thermique

Le traitement thermique est appliqué pour améliorer la résistance et la durabilité des contacts en cuivre, garantissant des performances durables.

-

Traitement de Surface

Les traitements de surface, tels que le placage ou le revêtement, sont appliqués pour améliorer la résistance à la corrosion et la conductivité électrique.

-

Test.

Des tests complets, y compris des tests de traction et de performance, sont effectués pour garantir que les contacts électriques répondent à toutes les normes de l'industrie.

-

Inspection finale

Une inspection finale est effectuée pour vérifier la qualité globale et la conformité aux spécifications avant l'emballage.

-

Emballage

Les contacts finis sont soigneusement emballés pour éviter tout dommage pendant le transport, garantissant qu'ils arrivent en parfait état.

-

Expédition

Les contacts électriques en cuivre terminés sont expédiés au client, garantissant une livraison ponctuelle et un transport en toute sécurité.

Traitements de Surface :

-

Anodisation

Un processus qui améliore la couche d'oxyde naturelle sur les surfaces métalliques, offrant une résistance accrue à la corrosion, une meilleure résistance à l'usure et une finition de surface améliorée.

-

Traitement Thermique

Un processus contrôlé utilisé pour modifier les propriétés physiques des matériaux, améliorant leur résistance, leur dureté et leur durabilité grâce à un chauffage et un refroidissement maîtrisés.

-

Revêtement par électrophorèse

Une méthode où des particules chargées sont déposées sur la surface d'une pièce à l'aide d'un champ électrique, créant un revêtement uniforme, résistant à la corrosion et offrant une excellente adhérence.

-

Revêtement en poudre

Un procédé de finition à sec dans lequel une fine poudre est appliquée sur la surface d'une pièce, puis durcie à l'aide de la chaleur, ce qui donne une finition durable et de haute qualité, résistante aux éclats, aux rayures et à la décoloration.

Pourquoi Nous Choisir ?

- Notre entreprise dispose de plus de 20 ans d'expertise dans la conception de moules métalliques et la production d'emboutissage de précision, garantissant des capacités de fabrication de haute qualité.

- Forte de 20 ans d'expérience dans le développement d'une clientèle internationale, l'entreprise a établi un solide bilan de succès en matière d'opérations d'exportation et de partenariats mondiaux.

- Certifiée ISO 9001 et IATF 16949, l'entreprise respecte des normes de qualité reconnues internationalement pour l'excellence manufacturière.

- Tous les produits sont conformes aux réglementations RoHS (Restriction des substances dangereuses), et des rapports complets sur les matériaux sont fournis pour garantir le respect des normes environnementales et de sécurité.

Notre Usine :