Aperçu :

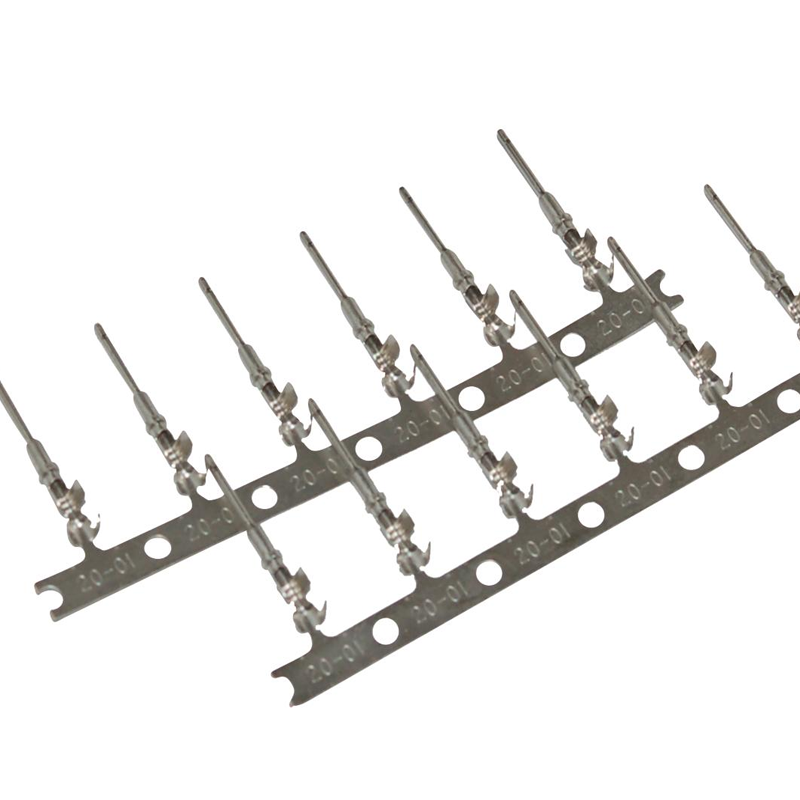

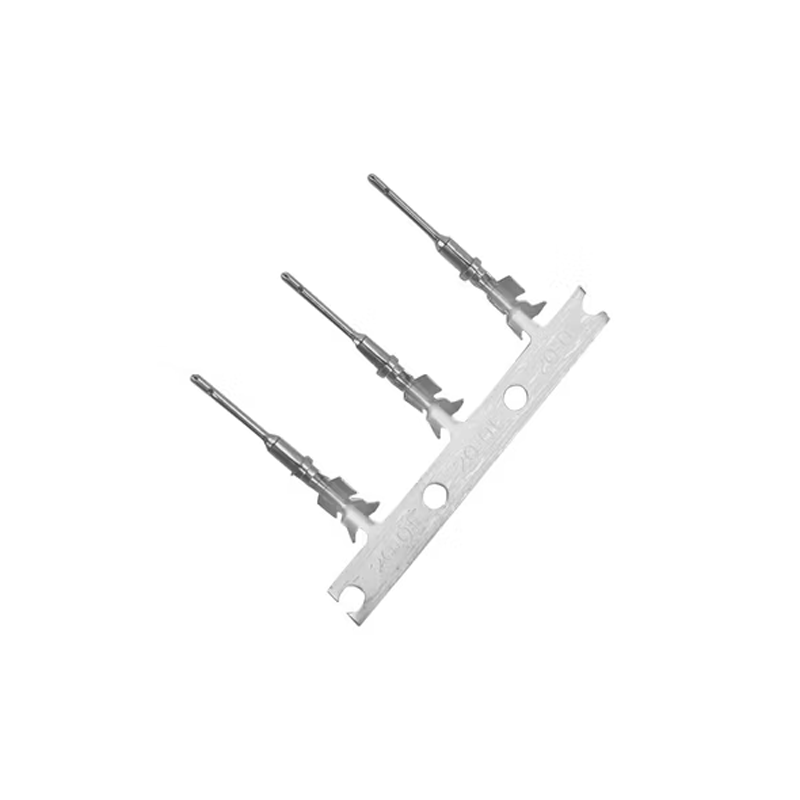

Nos bornes à broches en cuivre sont fabriquées à l'aide de techniques avancées d'estampage progressif, garantissant des connexions précises, durables et fiables pour vos systèmes électriques. Conçues pour un sertissage facile aux extrémités des fils, ces bornes offrent des performances électriques optimales et sont idéales pour une utilisation dans diverses applications, notamment l'électronique grand public, l'automobile et les systèmes de câblage industriels. Contactez-nous pour des bornes à broches en cuivre personnalisées répondant à vos exigences spécifiques.

Caractéristiques :

| Attribut | Détails |

| Lieu d'origine | Xiamen, Chine |

| Nom de la marque | OEM |

| Matériau | Laiton / Cuivre |

| Couleur | Personnalisé |

| Certificat | ISO9001, IATF16949 |

| Taille | Personnalisé |

| Tolérances | 0,01 mm |

| Service OEM | Offert |

Options de traitement de surface :

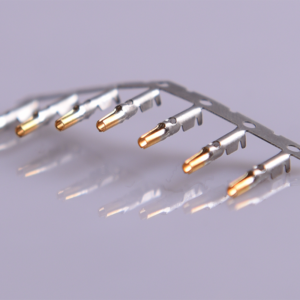

- Placage d'or : Améliore la conductivité, la résistance à la corrosion et offre une finition esthétique haut de gamme.

- Placage d'argent : Offre une excellente conductivité électrique et une grande résistance à la corrosion, idéal pour les applications haute performance.

- Placage au nickel : Offre durabilité, résistance accrue à l'usure et protection contre la corrosion, le rendant adapté à un large éventail d'applications industrielles.

- Placage d'Étain : Offre une excellente soudabilité, une résistance à la corrosion et est couramment utilisé pour les composants électroniques.

Processus de production :

- Préparation du Matériel : Des feuilles ou bobines de cuivre sont sélectionnées en fonction des spécifications requises, notamment l'épaisseur et la taille, afin de garantir les propriétés adéquates du matériau pour le processus d'emboutissage.

- Conception et Installation des Outils : Les outils progressifs sont conçus et installés dans des presses à emboutir. Ces outils sont conçus pour façonner progressivement le matériau en cuivre en formes de bornes à broches à travers plusieurs étapes d’emboutissage.

- Estampage Progressif : Le matériau en cuivre est introduit dans la presse d'estampage, où il subit une série de poinçons et de matrices qui forment progressivement la forme de la borne. Chaque étape dans l'ensemble de matrices crée une caractéristique spécifique, telle que la broche de la borne, les bords ou les motifs de trous.

- Ébarbage et Finition : Après la formation des bornes, l'excédent de matériau est éliminé, et les éventuels processus secondaires nécessaires, tels que l'ébavurage ou le nettoyage, sont réalisés afin de garantir une finition lisse et précise.

- Traitement de surface (optionnel) : En fonction de l'application, les bornes en cuivre peuvent subir des traitements de surface tels que le placage (par exemple, placage de nickel, d'étain ou d'or) pour améliorer la conductivité, la résistance à la corrosion et la durabilité.

- Contrôle de Qualité et Inspection : Les bornes de broches en cuivre finies sont soumises à des mesures strictes de contrôle de qualité, pouvant inclure des vérifications dimensionnelles, des tests fonctionnels et des inspections visuelles afin de garantir qu'elles respectent les normes et tolérances requises.

- Emballage et Livraison : Une fois que les bornes à pin en cuivre ont passé les contrôles de qualité, elles sont soigneusement emballées pour être livrées au client, garantissant ainsi qu'elles arrivent en parfait état pour une utilisation dans diverses applications.

Spectacle de l'Usine :

Nos installations de fabrication sont équipées d'une large gamme d'équipements de pointe conçus pour garantir la plus haute qualité de production. Cela inclut 25 presses à emboutir allant de 25 à 300 tonnes, des machines de découpe par fil EDM de précision, ainsi que des systèmes avancés de meulage, de soudage, de polissage et de nettoyage par ultrasons.

Avec les certifications ISO 9001 et IATF 16949, ainsi que des protocoles de contrôle qualité rigoureux, incluant l'utilisation de machines de mesure tridimensionnelle (CMM) pour des inspections précises, nous nous engageons à fournir des produits d'emboutissage métallique répondant aux normes les plus élevées de l'industrie.

With ISO9001 and IATF16949 certifications, coupled with stringent quality control protocols, including the use of Coordinate Measuring Machines (CMM) for precise inspections, we are committed to delivering metal stamping products that meet the highest industry standards.