Aperçu :

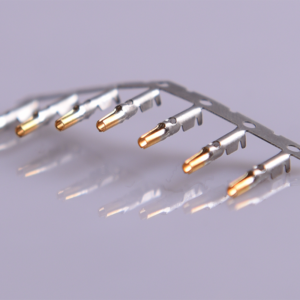

Nos produits de contacts électriques en argent sont méticuleusement conçus et fabriqués pour répondre aux normes les plus élevées de qualité et de fiabilité. En tirant parti de la technologie avancée de soudage en poinçon, nous garantissons une constance et une stabilité exceptionnelles des produits tout au long du processus de production.

Ces contacts électriques en métal argenté offrent non seulement des performances remarquables, mais également un avantage économique significatif. Grâce à l’utilisation de la technologie de soudage en poinçon, nous sommes en mesure de rationaliser la production, permettant ainsi une fabrication à grande échelle qui réduit les coûts et améliore l’efficacité globale de la production.

Détails :

| Spécification | Détails |

| Craftsmanship | Estampage, CNC |

| Terminer | Placage (Électrodéposition, Placage au nickel, etc.) |

| Prix | Tarification en Temps Réel pour l'Usine |

| Emballage | Intérieur : Sac en plastique et mousse PE ; Extérieur : Emballage en carton |

| Services | Services OEM disponibles pour des conceptions et spécifications personnalisées |

| Lieu d'origine | Xiamen, Chine |

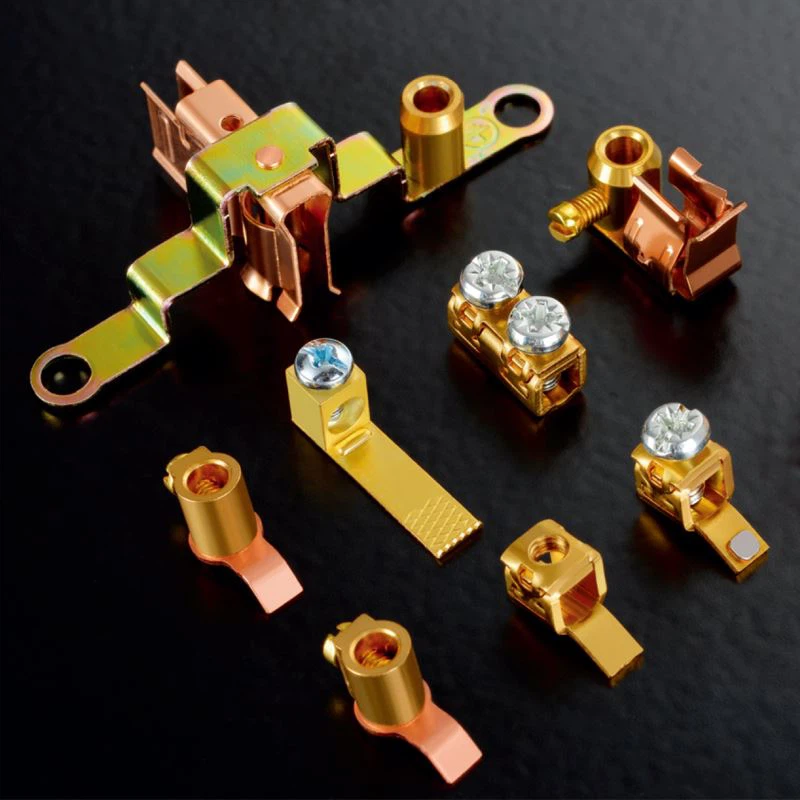

| Options de Matériaux | Aluminium, Acier inoxydable, Laiton, Cuivre, Plastique, etc. |

| Options de couleur | Blanc, Noir, Rouge, Bleu, Argent, Or, Couleurs personnalisées disponibles |

| Certifications | ISO9001:2015, Certifié SGS |

| Capacité de Production | 5 000 unités par jour (par machine) |

| Délai de Production | 7 à 15 jours selon la taille et la complexité de la commande |

| Test. | Inspection à 100 %, inspection par une tierce partie sur demande |

| Options d'expédition | DHL, FedEx, UPS, TNT, EMS, par voie maritime, par camion ou par train |

Processus de production :

- Sélection des matériaux : L'argent de haute pureté et d'autres matériaux d'alliage sont soigneusement sélectionnés pour garantir une excellente conductivité électrique, durabilité et résistance à la corrosion.

- Conception et Fabrication des Matrices : Des conceptions de matrices précises sont réalisées à l'aide de logiciels avancés de CAO/FAO afin de garantir une mise en forme optimale des composants de contact électrique. Les matrices sont ensuite fabriquées avec une grande précision grâce à l'usinage CNC ou d'autres techniques avancées.

- Estampage et Formage : Les matières premières sont estampées à l'aide de machines d'estampage de haute précision, formant ainsi la forme de base des contacts électriques. Ce processus est rigoureusement contrôlé afin de garantir des dimensions et une qualité constantes.

- Soudage dans le moule : Pour certains designs, la technologie de soudage dans le moule est utilisée pour assembler les composants pendant le processus d'emboutissage. Cela garantit des connexions solides et homogènes tout en éliminant la nécessité d'étapes d'assemblage supplémentaires.

- Traitement de surface : Les contacts électriques subissent divers traitements de surface tels que le placage, le polissage ou le revêtement afin d'améliorer leur durabilité, leur conductivité électrique et leur résistance à l'usure et à la corrosion.

- Inspection et tests : Chaque lot de contacts électriques en argent subit des tests rigoureux, comprenant des contrôles dimensionnels, des inspections visuelles et des tests de performance électrique, afin de garantir leur conformité aux spécifications et aux normes de l'industrie.

- Emballage : Une fois approuvés, les contacts électriques sont soigneusement emballés pour éviter tout dommage pendant le transport, garantissant qu'ils arrivent en parfait état.

- Expédition : Le produit final est ensuite expédié aux clients, avec des options pour une expédition express ou standard en fonction des exigences du client.

Options de traitement de surface :

Anodisation : Offre une finition durable et résistante à la corrosion avec une dureté de surface accrue, idéale pour les composants en aluminium.

Revêtement en poudre : Offre une finition résistante et de haute qualité qui résiste aux éclats, aux rayures et à la décoloration, disponible dans une large gamme de couleurs.

Peinture : Offre une finition lisse et esthétiquement agréable avec une excellente adhérence, idéale pour des applications à la fois protectrices et décoratives.

Sablage : Produit une texture mate et uniforme sur les surfaces métalliques, améliorant leur apparence et les préparant pour des traitements de finition ultérieurs.

Polissage : Permet d'obtenir une finition brillante et miroir qui améliore l'esthétique de la surface tout en offrant une texture lisse et raffinée.

Spectacle de l'Usine :