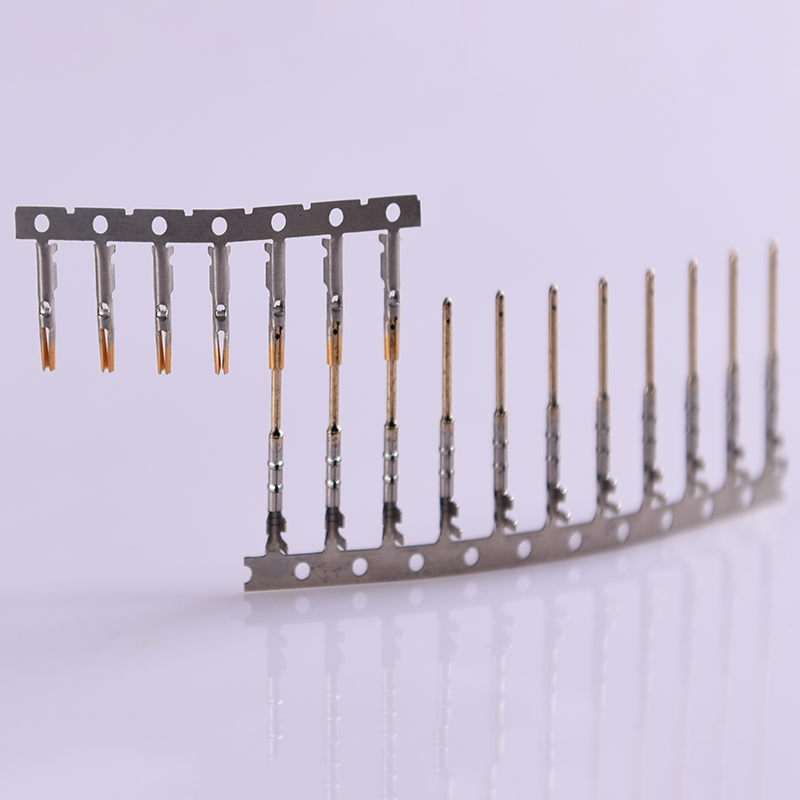

Overview:

Gold-plated male stamped connectors for the aviation industry are precision-engineered components designed to ensure reliable electrical connections in critical applications. Manufactured using advanced metal stamping processes and high-grade materials, these connectors feature gold plating to enhance conductivity, resist corrosion, and ensure long-lasting performance in demanding environments. Their role in the aviation industry is vital, as they support secure and efficient data transmission and power distribution in aircraft systems, contributing to overall safety and operational efficiency. Partner with us to explore custom connector solutions tailored to meet the rigorous standards of the aviation sector.

Features:

| Attribute | Details |

| Application | Aviation |

| Production Process | Cold Pressing |

| Shape | Custom |

| Certification | CQC, ISO9001:2015 |

| Brand | OEM |

| Color | Gold Plated / Nickel Plated / Tin Plated / Silver Plated |

| Special Features | OEM Service Offered |

| Surface Treatment | Coated Tin |

| Usage | Connecting Cable |

| Lead Time (Days) | 30 Days |

| Drawing Format | 2D, 3D Drawing Software |

| Shipping Method | FOB, CIF, EXW |

| MOQ | Negotiable |

| Trademark | Custom |

| Origin | Xiamen, China |

| Production Capacity | 10,000 PCS/Day |

Production Process:

-

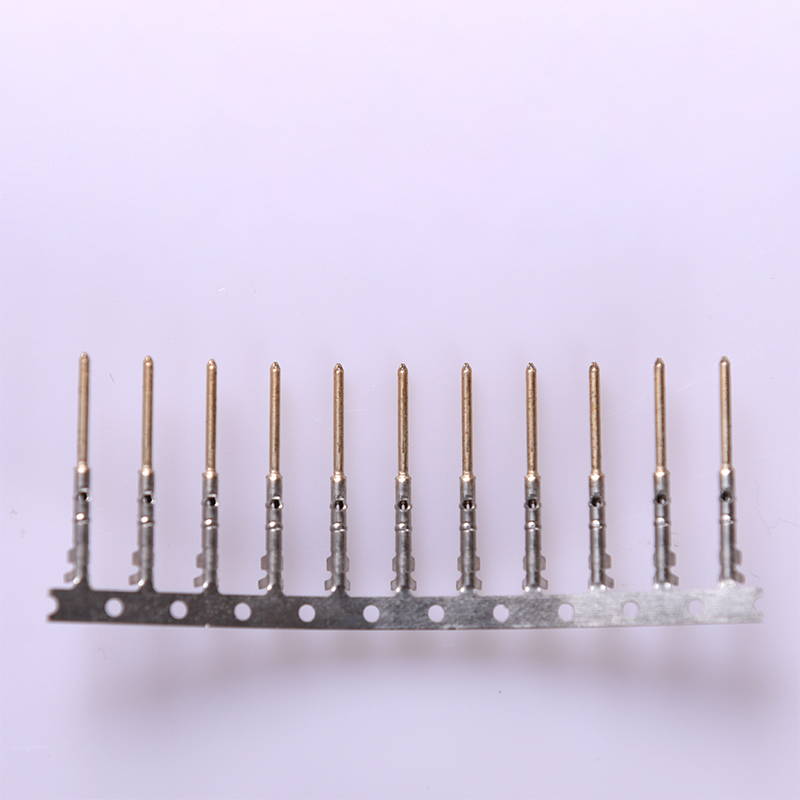

Material Selection

High-quality base materials, such as copper or brass, are carefully chosen for their excellent conductivity and durability, meeting the rigorous demands of aviation applications.

-

Precision Stamping

Using advanced stamping machinery, the connectors are shaped with exceptional precision, ensuring tight tolerances and consistent quality for critical aviation standards.

-

Surface Preparation

The stamped connectors undergo meticulous cleaning and polishing to remove any impurities, ensuring optimal adhesion during the plating process.

-

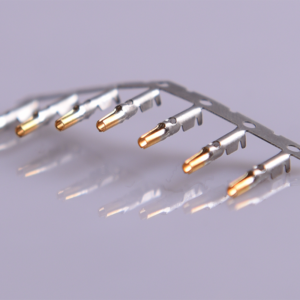

Gold Plating Process

A controlled electroplating technique is used to deposit a uniform layer of gold, enhancing corrosion resistance, electrical conductivity, and wear performance.

-

Quality Inspection

Each connector undergoes thorough quality control tests, including dimensional accuracy, plating thickness measurement, and conductivity evaluation, ensuring compliance with aviation industry standards.

-

Packaging and Delivery

The finished connectors are packaged using industry-approved methods to prevent damage during transport and are delivered on schedule to meet customer requirements.

Post-Surface Treatments for Connectors:

– Gold Plating

Provides superior corrosion resistance, excellent electrical conductivity, and enhanced durability, ideal for high-performance applications.

– Silver Plating

Delivers exceptional conductivity and thermal performance, making it suitable for demanding environments with high electrical requirements.

– Nickel Plating

Offers excellent wear resistance and a robust protective layer against corrosion, ensuring longevity and reliability in harsh conditions.

– Tin Plating

Ensures solderability and effective corrosion resistance, making it a cost-effective solution for general-purpose applications.

Our Factory:

We utilize an extensive array of cutting-edge facilities and equipment to guarantee top-tier production quality. Our manufacturing operations feature 25 punch presses with capacities ranging from 25 to 300 tons, advanced wire EDM machines, precision grinding tools, welding and polishing equipment, and ultrasonic cleaning systems.

To further enhance the durability, aesthetics, and performance of our metal stamping products, we provide a comprehensive range of plating services. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing, all performed in our state-of-the-art plating facilities designed for uniform finishes, superior corrosion resistance, and adherence to stringent industry standards.

By combining fully automated production lines, sophisticated machinery, stringent quality assurance protocols, and premium plating capabilities, we consistently deliver metal stamping products that meet and exceed the highest industry benchmarks.