Overview:

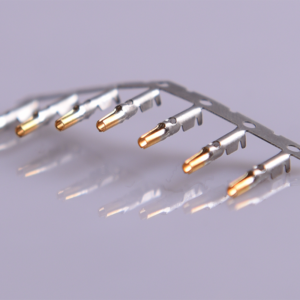

Gold Plating Stamping Terminal Connectors are precision-engineered components typically made using high-quality progressive dies processes, with a gold plating finish to enhance conductivity and corrosion resistance. These connectors are commonly used in industries such as electronics, automotive, telecommunications, and medical devices, offering superior performance and reliability. The gold plating ensures long-lasting, stable connections, even in harsh environments.

We offer custom manufacturing services for these connectors, including tailored surface treatments (e.g., gold, nickel, or tin plating), size adjustments, color options, and other specific requirements to meet your unique needs. Whether it’s for small or large-scale production, we deliver high-quality, precision connectors designed to fit your exact specifications.

Details:

| Category | Details |

| Processing Type | Shaping Metal |

| Material | Copper |

| Mould | Multistep Progressive Dies |

| Surface Processing | Gold Plating |

| Industry | Metal Stamping Parts |

| Tolerances | ±0.01mm |

| Available Material | Copper, Aluminum, etc. |

| Environmental Friendly | Yes, ISO9001 Certification Passed |

| Testing | Horizontal & Vertical Flame Test, Salt Spray Test |

| Transport Package | Custom |

| Specification | Customized |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 5000 PCS/Day in One Machine |

Production Process:

-

Material Selection

High-quality copper is selected as the base material due to its excellent conductivity and durability.

-

Progressive Die Stamping

The copper is fed into multi-step progressive dies, which precisely cut and shape the material into terminal connectors.

-

Gold Plating

After shaping, the connectors undergo a gold plating process to enhance conductivity, provide corrosion resistance, and ensure a high-quality finish.

-

Surface Treatment

The connectors may also undergo additional surface treatments, such as polishing or cleaning, to ensure smoothness and improve overall performance.

-

Testing and Inspection

Rigorous testing, including horizontal and vertical flame tests and salt spray tests, are performed to ensure compliance with industry standards and ensure long-lasting performance.

-

Packaging

Once the connectors pass quality checks, they are carefully packaged, ready for delivery or further assembly.

Why Choose Us?

-

OEM & Assembly Services

Offering customized OEM solutions and assembly services since 2000.

-

Comprehensive One-Stop Service

Providing a full range of products including stamping parts, CNC lathe and milling parts, springs, shafts, fasteners, and more.

-

Certified Supplier

A trusted second-tier supplier with passed factory audits and certifications including RoHS and HE compliance.

-

Quality Management Certifications

Certified with ISO 9001:2015 and IATF 16949 for high standards of quality management.

Factory Show:

Our production facility is equipped with a diverse range of advanced machinery to guarantee the highest standards of manufacturing. We operate 25 punch presses, ranging from 25 to 300 tons, along with precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems, ensuring precise and efficient production.

To further elevate the quality, durability, and aesthetics of our metal stamping products, we offer a comprehensive selection of metal plating options. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing, all performed in our cutting-edge plating facilities. This ensures uniform coating, enhanced corrosion resistance, and adherence to industry regulations.

By integrating professional, automated production lines with advanced equipment and stringent quality control processes, we consistently deliver metal stamping components that meet the highest industry standards.