Overview

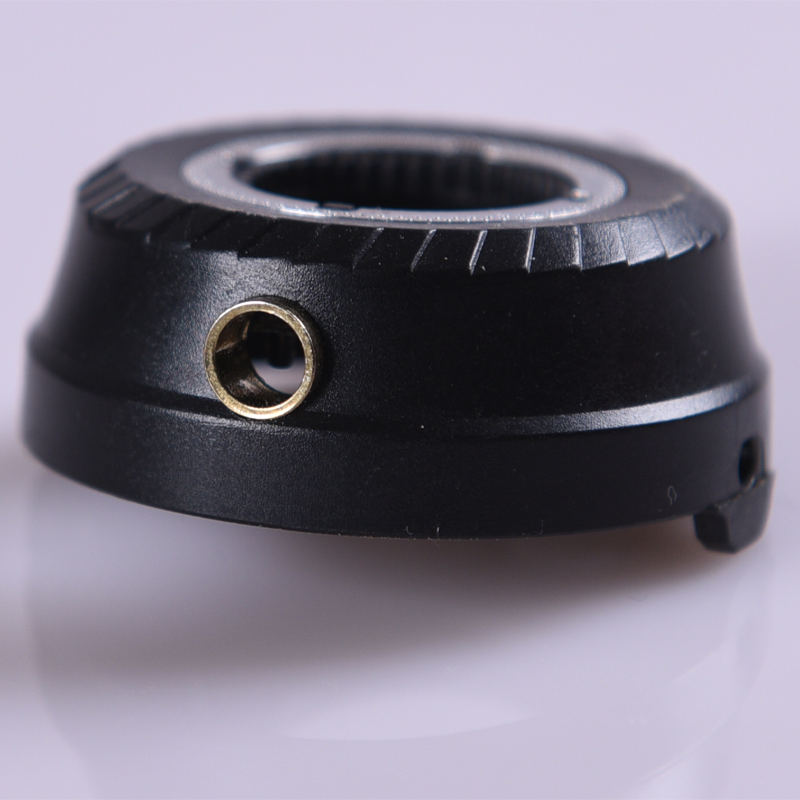

The Headset Shell Assembly is a crucial component of a headset, designed to house and protect internal parts while ensuring durability and comfort. Made from high-quality materials, this assembly provides a secure outer casing for the headset’s electronic and acoustic elements. It is engineered for easy assembly and long-lasting performance, making it ideal for use in professional call centers, offices, and personal audio devices. The Headset Shell Assembly ensures both functional protection and a sleek, ergonomic design for enhanced user experience.

The Production Process for Our Metal Stamping Parts:

-

Order Receipt and Drawing Review

– Receive and review customer orders, including technical drawings in formats such as DXF, IGS, STEP, or PDF.

-

Design Confirmation

– Confirm design details with the customer to ensure accuracy before production begins.

-

Material Preparation

– Select and prepare metal sheets according to the required specifications.

-

Precision Cutting

– Utilize laser cutting and CNC shearing to cut metal sheets to precise dimensions.

-

Forming and Shaping

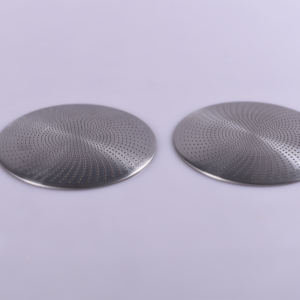

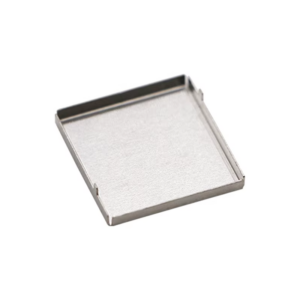

– Perform bending, punching, and stamping to achieve the desired shapes and features.

-

Welding and Riveting

– Join metal components using advanced welding techniques and riveting.

-

Surface Treatment

– Apply necessary surface treatments, including plating and spraying, to enhance durability and appearance.

-

Assembly and Quality Control

– Assemble the components and conduct rigorous quality checks to ensure adherence to specifications.

-

Packaging and Shipping

– Package finished parts securely and manage logistics for timely delivery to the customer.

-

After-Sales Support

– Provide ongoing support and address any post-delivery issues to ensure customer satisfaction.

Quality Control

Quality is our foremost priority. At the outset of each project, we conduct a feasibility review of the metal parts to ensure manufacturability. We also perform a run-at-rate study during the initial production run to validate quality before proceeding to large-scale manufacturing. This allows our quality and production management teams to closely monitor controls and ensure smooth operations. Once testing is completed successfully, we proceed with the production of the first batch of conforming metal parts.

Our quality management system is built on advanced technology and controls, continuous improvement initiatives, and a state-of-the-art quality laboratory and team. Throughout our production facility, we utilize in-line and off-line camera vision systems and sensor technology, customized for each production program. Our vision system technology integrates with our stamping machinery to meticulously inspect and verify part features and dimensions using automated camera imaging. This rigorous quality control process guarantees that every metal part produced meets our high standards, ensuring 100% quality and zero defects.

Why Choose Us?

-

Wide Selection and Prompt Delivery

We offer a diverse range of options and ensure timely delivery.

-

Extensive Sales Network

Our well-established sales network supports comprehensive market reach.

-

Advanced Production Equipment and Techniques

We utilize state-of-the-art equipment and innovative production methods.

-

Competitive Pricing with Exceptional Service

Enjoy competitive pricing paired with our commitment to excellent customer service.

-

Custom Designs Available

We accommodate various design requests to meet customer specifications.

-

Rigorous Quality Testing

Our advanced testing equipment ensures 100% inspection of critical dimensions for superior quality.