Panoramica:

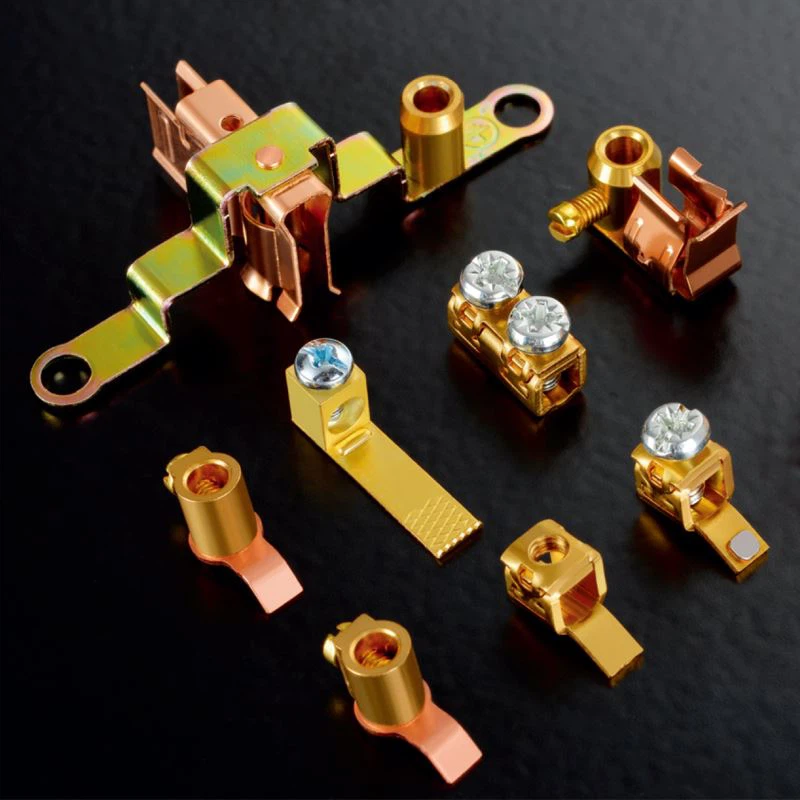

I nostri prodotti di contatti elettrici in argento sono progettati e realizzati con la massima precisione per soddisfare i più alti standard di qualità e affidabilità. Grazie all'uso della tecnologia avanzata di saldatura in stampo, garantiamo un'eccezionale uniformità e stabilità del prodotto durante l'intero processo produttivo.

Questi contatti elettrici in metallo d'argento non solo offrono prestazioni straordinarie, ma rappresentano anche un significativo vantaggio economico. Utilizzando la tecnologia di saldatura in stampo, siamo in grado di ottimizzare la produzione, consentendo una fabbricazione su larga scala che riduce i costi e migliora l'efficienza complessiva del processo produttivo.

Dettagli:

| Specifica | Dettagli |

| Craftsmanship | Stampaggio, CNC |

| Finire | Placcatura (Galvanostegia, Placcatura al Nichel, ecc.) |

| Prezzo | Prezzi in Tempo Reale per la Fabbrica |

| Imballaggio | Interno: Sacchetto di plastica e schiuma PE; Esterno: Imballaggio in cartone |

| Servizi | Servizi OEM disponibili per design e specifiche personalizzati. |

| Luogo di Origine | Xiamen, Cina |

| Opzioni Materiali | Alluminio, Acciaio Inossidabile, Ottone, Rame, Plastica, ecc. |

| Opzioni Colore | Bianco, Nero, Rosso, Blu, Argento, Oro, Colori personalizzati disponibili |

| Certificazioni | ISO9001:2015, Certificato SGS |

| Capacità di Produzione | 5.000 unità al giorno (per macchina) |

| Tempo di Consegna | 7–15 giorni, a seconda delle dimensioni e della complessità dell'ordine. |

| Collaudo | Ispezione al 100%, Ispezione da parte di terzi su richiesta |

| Opzioni di Spedizione | DHL, FedEx, UPS, TNT, EMS, via mare, via camion o via treno |

Metalli di alta qualità come rame, ottone e altre leghe vengono selezionati con cura per la loro conduttività elettrica e resistenza meccanica, che sono fondamentali per garantire connessioni affidabili nei componenti elettronici.

- Selezione dei Materiali: Argento ad alta purezza e altri materiali in lega sono accuratamente selezionati per garantire un'eccellente conducibilità elettrica, durata e resistenza alla corrosione.

- Progettazione e Realizzazione degli Stampi: I progetti degli stampi di precisione vengono creati utilizzando software CAD/CAM avanzati per garantire la formatura ottimale dei componenti dei contatti elettrici. Gli stampi vengono quindi realizzati con estrema precisione mediante lavorazioni CNC o altre tecniche avanzate.

- Stampaggio e Formatura: I materiali grezzi vengono stampati utilizzando macchine di stampaggio ad alta precisione, formando la forma di base dei contatti elettrici. Questo processo è attentamente monitorato per garantire dimensioni e qualità costanti.

- Saldatura In-Die: Per alcuni design, la tecnologia di saldatura in-die viene utilizzata per unire i componenti durante il processo di stampaggio. Questo garantisce connessioni solide e senza interruzioni, eliminando la necessità di ulteriori fasi di assemblaggio.

- Trattamento Superficiale: I contatti elettrici subiscono vari trattamenti superficiali come placcatura, lucidatura o rivestimento per migliorare la loro durata, la conducibilità elettrica e la resistenza all'usura e alla corrosione.

- Ispezione e Test: Ogni lotto di contatti elettrici in metallo d'argento viene sottoposto a rigorosi test, tra cui controlli dimensionali, ispezioni visive e test di prestazioni elettriche per garantire la conformità alle specifiche e agli standard del settore.

- Imballaggio: Una volta approvati, i contatti elettrici vengono accuratamente imballati per prevenire danni durante la spedizione, garantendo che arrivino in condizioni ottimali.

- Spedizione: Il prodotto finale viene quindi spedito ai clienti, con opzioni di spedizione rapida o standard a seconda delle esigenze del cliente.

Opzioni di Trattamento Superficiale:

Anodizzazione: Fornisce una finitura durevole e resistente alla corrosione con una maggiore durezza superficiale, ideale per componenti in alluminio.

Verniciatura a polvere: Offre una finitura resistente e di alta qualità che resiste a scheggiature, graffi e sbiadimento, disponibile in una vasta gamma di colori.

Pittura: Offre una finitura liscia ed esteticamente gradevole con eccellente adesione, ideale sia per applicazioni protettive che decorative.

Sabbiatura: Produce una texture uniforme e opaca sulle superfici metalliche, migliorandone l'aspetto e preparandole per ulteriori trattamenti di finitura.

Lucidatura: Ottiene una finitura lucida e a specchio che migliora l'estetica della superficie, offrendo al contempo una texture liscia e raffinata.

Mostra della Fabbrica: