Descrizione:

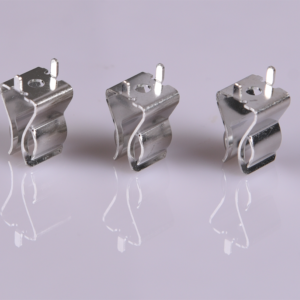

Le clip metalliche in acciaio inossidabile stampate su misura sono componenti progettati con precisione e realizzati tramite il processo di stampaggio metalli, utilizzando materiali di alta qualità come acciaio inossidabile, acciaio per molle e acciaio al carbonio. Queste clip sono realizzate per soddisfare specifici requisiti di prestazione in varie applicazioni, tra cui automotive, aerospaziale e macchinari industriali. Offriamo dimensioni personalizzate e un'ampia gamma di opzioni di trattamento superficiale, come zincatura, ossidazione nera o passivazione, per migliorare la durata, la resistenza alla corrosione e le prestazioni generali.

Le clip metalliche stampate possono fungere da morsetti, fissaggi o staffe, applicando pressione per tenere saldamente uniti gli oggetti. Le nostre clip metalliche personalizzate sono ampiamente utilizzate in applicazioni come cruscotti, gruppi parafanghi, sistemi frenanti ABS e interruttori di controllo. Con la nostra esperienza nella progettazione personalizzata e nella produzione di precisione, forniamo soluzioni che soddisfano le vostre specifiche esatte e garantiscono prestazioni affidabili e di alta qualità in ambienti difficili.

Caratteristiche:

| Attributo | Dettagli |

| Tipo di Elaborazione | Plasmare il Metallo |

| Materiale | Zinco, Alluminio, Rame, Acciaio, Ottone, ecc. |

| Stampo | Stampi progressivi multistadio |

| Stampa di precisione | Multiposizione |

| Processo | Stampaggio, Piegatura, Taglio Laser, Saldatura |

| Industria | Parti Stampate in Metallo |

| Tolleranze | ±0,01 mm |

| Personalizzato | Disponibile |

| Spessore | 0,1 mm – 12 mm |

| Certificazione | ISO 9001:2015, RoHS |

| Marchio di fabbrica | OEM |

| Pacchetto di Trasporto | Sacchetto di plastica/Imballaggio a bolle + Scatole di cartone + Cassa di legno |

| Specifica | OEM |

| Origine | Cina |

Opzioni di Superficie:

-

Elettrodeposizione

Un processo in cui un sottile strato di metallo viene depositato sulla superficie delle clip tramite una reazione elettrochimica, migliorando la resistenza alla corrosione e la durata.

-

Rivestimento a spruzzo

Una tecnica che applica un sottile strato nebulizzato di materiale di rivestimento sulla superficie delle clip, fornendo una finitura uniforme e migliorando al contempo la protezione contro l'usura e i fattori ambientali.

-

Lucidatura

Un processo di finitura meccanica che leviga la superficie delle clip, migliorandone l'estetica e conferendo un aspetto raffinato e lucido.

-

Ossidazione

Un metodo di trattamento che crea uno strato controllato di ossido sulla superficie metallica, migliorando la resistenza alla corrosione e aumentando la longevità complessiva delle clip.

I nostri vantaggi

-

Competenza specializzata nella produzione OEM

Siamo specializzati nella produzione di una vasta gamma di componenti OEM, inclusi componenti stampati in metallo, lavorati a macchina, imbutiti e formati da lamiera, con una varietà di finiture superficiali personalizzate in base alle specifiche del cliente.

-

Vantaggio di Posizione Strategica

La nostra struttura a Dongguan, nella provincia del Guangdong, offre una vicinanza strategica ai principali porti di Shenzhen, consentendoci di fornire soluzioni di spedizione più rapide ed economiche, migliorando al contempo le nostre capacità di servizio per i clienti internazionali.

-

Macchinari Avanzati e Manodopera Qualificata

Dotati di macchinari all'avanguardia per punzonatura, saldatura, lavorazione CNC, fresatura e rettifica, garantiamo precisione e affidabilità in ogni fase della produzione. Il nostro personale qualificato opera questi sistemi avanzati con la massima cura e attenzione ai dettagli.

-

Competenza e supporto tecnico dedicati

Il nostro team è composto da tecnici esperti focalizzati sul continuo sviluppo tecnologico, il che ci garantisce di rimanere all'avanguardia nell'innovazione manifatturiera. Supportati da un team dedicato di ingegneri professionisti e specialisti del commercio estero, ci impegniamo a fornire un supporto e un servizio eccezionali ai nostri clienti.

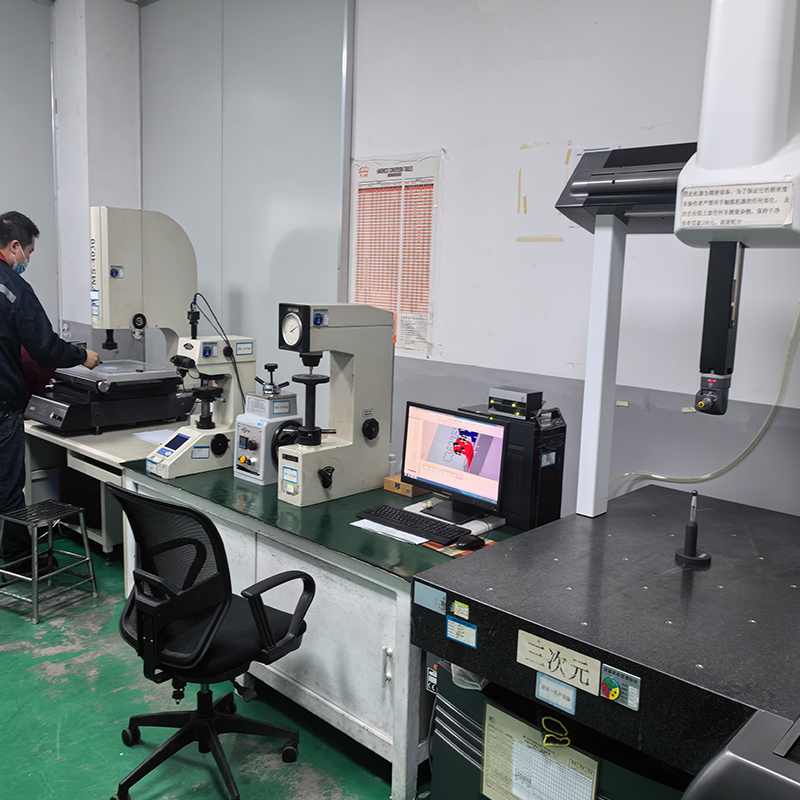

Mostra della Fabbrica:

Gestiamo una vasta gamma di impianti e attrezzature per garantire una produzione di altissima qualità. Le nostre strutture sono dotate di 25 presse a punzonatura con capacità che vanno da 25 tonnellate a 300 tonnellate, macchine EDM a filo di precisione, attrezzature per la rettifica, strumenti per saldatura e lucidatura, e sistemi di pulizia a ultrasuoni.

Oltre alle nostre capacità produttive, offriamo una varietà di processi di placcatura dei metalli per migliorare la durabilità, l'aspetto e la funzionalità dei nostri prodotti di stampaggio metallico. Questi includono galvanizzazione, placcatura allo zinco, placcatura al nichel, placcatura al cromo e anodizzazione. I nostri impianti di placcatura all'avanguardia garantiscono finiture uniformi, resistenza alla corrosione e conformità agli standard del settore.

Questa combinazione di linee di produzione professionali e automatizzate, attrezzature meccaniche avanzate, rigorose misure di controllo qualità e processi di placcatura di alta qualità garantisce la consegna di prodotti di stampaggio metallico al massimo standard.