At Plantmetal, we specialize in providing high-quality short run metal stamping services designed to meet the needs of industries that demand precision, efficiency, and cost-effectiveness for low-volume production. As the name implies, short run metal stamping refers to projects with a relatively small quantity of parts. While the specific definition of a “short run” can vary among metal stampers, most consider an order with fewer than 50,000 units to fall under this category. However, what truly distinguishes a short run is the rapidity with which the parts are produced. Whether it’s for a single production run or a limited production cycle, short run stamping is an ideal solution for projects that require fast turnaround times without compromising on quality.

The short run metal stamping process is particularly suited to several key applications, such as prototyping, modular stamping, and deep draw forming. These methods offer distinct advantages that streamline production, reduce costs, and ensure superior part precision—all critical elements when working with limited quantities. Let’s take a closer look at how short run stamping works and why it’s such a valuable option for businesses looking to bring products to market quickly and efficiently.

Driving Rapid Prototyping with Short Run Stampaggio dei metalli

In today’s fast-paced industrial landscape, product development cycles have dramatically shortened. Companies are under increasing pressure to move from concept to fully developed product faster than ever before. As a result, rapid prototyping has become an essential method for businesses looking to test and refine their designs quickly.

Short run metal stamping plays a critical role in this process. Unlike other prototyping methods, which might produce parts that are far from the final product, metal stamping allows for the creation of highly accurate prototypes that closely resemble the finished product. Thanks to our advanced stamping technologies, Plantmetal ensures the parts produced are of superior quality—almost indistinguishable from their mass-produced counterparts.

What sets short run metal stamping apart from other prototyping methods, such as casting or machining, is its ability to keep production costs low without sacrificing quality. By utilizing standard tooling and producing minimal waste, metal stamping ensures that your prototype is cost-efficient to produce. This cost-effective approach means that businesses can get their products to market faster, without incurring the hefty expenses typically associated with more labor-intensive methods like casting or machining.

Modular Stamping: Precision and Flexibility

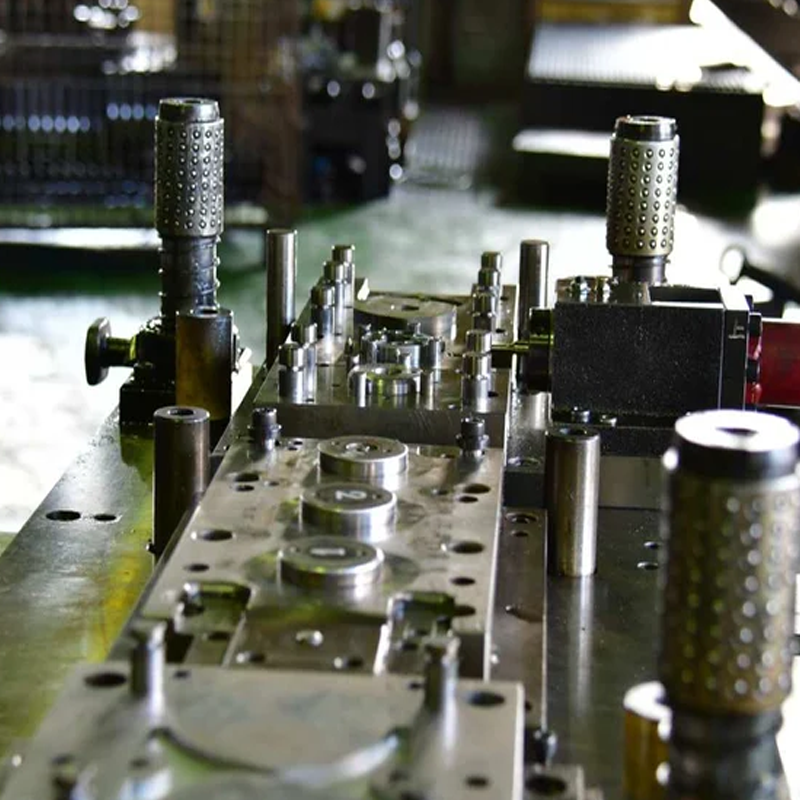

One of the most efficient methods for short run metal stamping is modular stamping, which offers a number of key benefits, especially when dealing with low-volume orders. The process is particularly advantageous for projects that require fast setup times and minimal lead times. At Plantmetal, we use modular stamping with pre-made tooling that simplifies the setup process, making it an excellent choice for projects that need quick turnarounds.

Modular stamping works by applying force via a hydraulic press, ranging from 3 to 300 tons, depending on the requirements of the part. Standard machine tooling is then used to cold-form the metal into the desired shape. This process is repeated until all features of the part are fully formed. The benefit of this method lies in its precision and repeatability, ensuring that each part produced meets the highest quality standards.

With the use of a hydraulic press control panel, the modular stamping process is fully automated, which helps reduce costs for customers. While it doesn’t offer the same throughput as progressive stamping, it remains an extremely cost-effective option for low-volume runs. This makes it ideal for clients who need high-precision parts but don’t require the large-scale output typical of traditional stamping methods.

Deep Draw Stamping: Shaping Complex Forms with Precision

When it comes to forming complex shapes, deep draw stamping stands out as one of the most versatile and efficient techniques for producing high-precision parts. Whether you need a part with a large depth or intricate geometry, deep draw stamping is capable of achieving forms that would otherwise be difficult or impossible to produce using other metal forming methods.

At Plantmetal, we utilize cutting-edge deep draw stamping equipment, including a state-of-the-art servo press capable of exerting up to 220 tons of force. This allows us to create parts with depths as great as 5 inches and diameters as wide as 14 inches. The precision and repeatability of this process are unmatched, especially for parts that require large dimensions or a high level of complexity.

Though deep draw stamping typically requires custom tooling, once this tooling is created, it can be reused to reproduce parts with the same level of precision over time. The long-term cost savings are significant, particularly when compared to casting or machining, which require extensive post-production finishing work or result in significant material waste.

In addition to the reduction in lead times, deep draw stamping also helps lower production costs, thanks to its efficient use of materials. For companies currently relying on casting or machining methods, converting to deep draw stamping can lead to significant savings and faster time-to-market, making it an ideal choice for industries that require both precision and cost-effectiveness.

Why Choose Plantmetal for Short Run Metal Stamping?

At Plantmetal, we pride ourselves on delivering high-quality metal stamping services tailored to your specific needs. With over 90 years of experience in the metal forming industry, our team of engineers and technicians is equipped with the expertise and technology to tackle any short run stamping project. Whether you need prototyping, modular stamping, or deep draw forming, we provide efficient, cost-effective solutions that meet the demands of your project.

What sets us apart is our commitment to customer satisfaction. We work closely with you throughout the production process to ensure that every part meets your specifications. Our state-of-the-art equipment, combined with our extensive experience, enables us to produce high-precision parts quickly and cost-effectively—no matter the complexity of your project. Whether you’re looking to create prototypes, low-volume production runs, or complex components, we’ve got you covered.

If you’re looking for a trusted partner for your next short run metal stamping project, don’t hesitate to get in touch. Our team at Plantmetal is ready to discuss your needs, provide you with a free consultation, and help you navigate the best stamping solutions for your project.

Contact Plantmetal Today

Ready to get started on your next metal stamping project? Plantmetal is here to offer you the expertise, speed, and precision you need for short run metal stamping that drives innovation. From prototyping to complex forming, we can help bring your vision to life with our high-quality solutions.

Don’t wait—contact us today to learn more about how Plantmetal can support your project. Whether you need expert guidance or are ready to dive into production, our team of metal forming specialists is here to help. Call now or schedule an in-person meeting to discuss how we can help with your metal stamping needs.

We hope this blog provides valuable insight into the advantages of short run metal stamping and why Plantmetal is your ideal partner for these projects. For more information or to discuss your project, reach out to us today!