Struggling with ultra-tight tolerances or intricate part geometries on your next metal stamping project? At Plantmetal, we understand how critical it is to get it right the first time. You’re not just buying stamped metal—you’re investing in reliability, repeatability, and risk-free production. That’s where our meticulous First Article Inspection (FAI) process comes in. From the moment your design hits our engineering desk to the time we deliver that first validated part, we prioritize precision and partnership. In this article, we’ll walk you through how our FAI process works, why it’s a vital step in your manufacturing journey, and how Plantmetal’s commitment to quality gives you the confidence to scale.

Understanding First Article Inspection (FAI)

First Article Inspection (FAI) is more than just another quality checkpoint—it’s a systematic, high-resolution look at the first part produced under real manufacturing conditions. Whether we’re stamping high-strength steel for automotive parts or intricate aluminum components for consumer electronics, the goal of FAI is to ensure every specification is met before full production begins.

Unlike general in-process inspections or end-of-line testing, FAI verifies:

– All dimensional tolerances per engineering drawings

– Material properties, including certifications and hardness

– Surface finish quality and coating performance

– Functional characteristics and fit

– Tooling setups, press parameters, and die alignment

For industries where every micron counts, FAI acts as a gatekeeper—preventing issues before they impact your downstream processes.

From Analog Tools to Smart Systems: The Evolution of FAI

- Early-Stage Inspection Methods

In the past, FAI was largely manual—think dial calipers, micrometers, and handwritten notes. While functional, these methods lacked the consistency and traceability that modern industries demand.

- Standardization and Structure

The evolution of formal quality systems brought with it standardization. Aerospace industries led the charge with AS9102, followed by the automotive sector’s PPAP (Production Part Approval Process). These standards provided structured workflows and consistent documentation templates, paving the way for improved quality across global supply chains.

- Digitization and Integration

Modern FAI has entered the digital age. Today, we use:

– CAD-to-FAI automation: Critical dimensions and GD&T callouts flow directly into inspection reports.

– Ballooned drawings: Automatically linked to data tables for clarity and efficiency.

– CMMs and 3D scanning: For ultra-accurate dimensional verification.

– Digital archives: Ensuring traceability and easy future reference.

- Future-Forward FAI

Emerging technologies like augmented reality (AR)-guided inspections, cloud-based FAI platforms, and AI-driven defect recognition are shaping the next generation of quality control. At Plantmetal, we’re already integrating digital twins and smart reporting to support customers across time zones and technical requirements.

Why FAI Is Critical for Metal Stamping Projects

When producing stamped components, small deviations can lead to major setbacks. An out-of-spec hole or warped edge can delay assembly, compromise strength, or cause misalignments in downstream applications. Here’s how our FAI process protects your production line:

– Press & Tooling Validation: Confirming die setup, alignment, and press tonnage before full runs ensures process reliability.

– Early Nonconformance Detection: Identifying issues at the sample stage prevents costly batch-level rework.

– Waste Minimization: Material, time, and labor are conserved when defects are caught before ramp-up.

– Consistency Across Orders: A fully documented “golden part” serves as the master reference for all repeat production.

– Regulatory & Customer Compliance: We ensure adherence to global standards like ISO 9001, AS9102, and IATF 16949.

Plantmetal’s Step-by-Step FAI Process

Here’s a closer look at how we manage FAI with the precision and care your project deserves:

| Step | What We Do |

| 1. Engineering Analysis | We review your design documents in detail, highlighting key tolerances, finishes, and functional requirements. |

| 2. Production Setup | Tooling, dies, and machine parameters are configured exactly as they will be in full-scale production. |

| 3. First-Off Production | A small sample batch is created under actual production conditions, using your specified materials. |

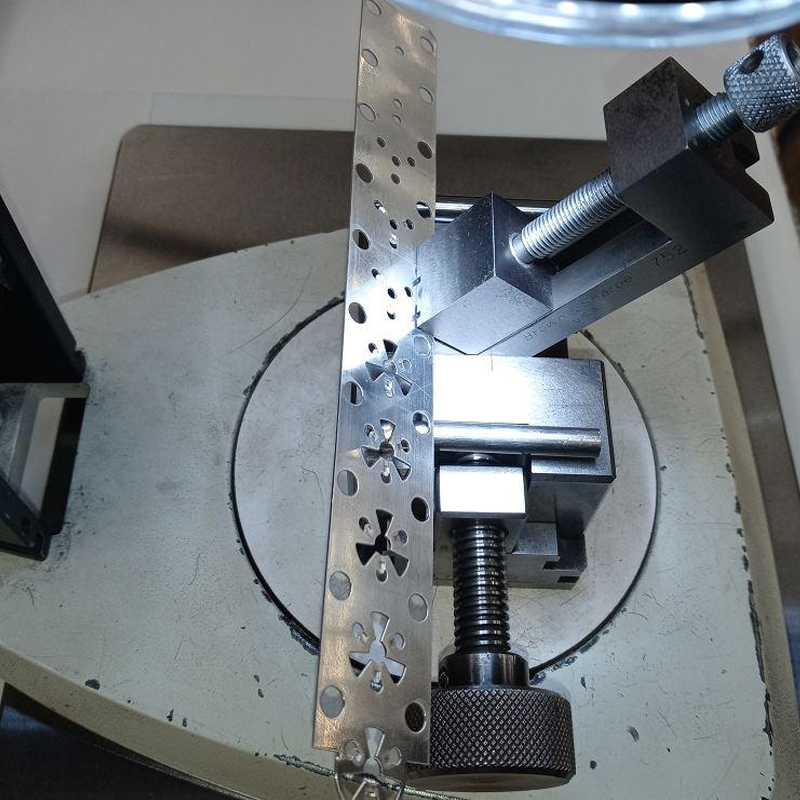

| 4. Dimensional Validation | CMMs and calibrated hand tools confirm dimensions, flatness, hole positioning, and geometric features. |

| 5. Surface & Finish Inspection | We check for burrs, coating integrity (e.g., plating, anodizing), and visual appearance per your standards. |

| 6. Material Testing | Material certificates, tensile strength, and hardness results are reviewed and recorded. |

| 7. Reporting & Documentation | Annotated ballooned drawings, actual-to-nominal data tables, and certification files are compiled. |

| 8. Customer Approval | You receive the complete FAI report for review and approval before production proceeds. |

Anticipating & Overcoming Common FAI Challenges

At Plantmetal, we understand that not every project is straightforward. That’s why we proactively tackle FAI-related challenges:

– Ambiguous Drawings? Our engineers collaborate with yours to clarify intent and suggest DFM (Design for Manufacturability) improvements.

– Tight Deadlines? Our automated systems speed up inspection cycles without compromising accuracy.

– Language Barriers? We offer multilingual FAI reports—available in English, Spanish, or your preferred language.

– Communication Gaps? Regular status updates, clear deviation tracking, and dedicated support keep you informed at every step.

After FAI: What Happens Next?

– If Approved (Pass):

– Full production begins

– First article archived as your reference standard

– All inspection data logged for traceability

– If Not Approved (Fail):

– An NCR (Non-Conformance Report) is issued

– Corrective action plans are executed

– Adjustments are made, and a revised FAI is submitted

– Production remains on hold until full compliance is achieved

Why FAI Is a Must in Global Sourcing

If you’re working with international vendors, FAI becomes even more essential. Time zones, language differences, and varying quality expectations can create friction. Plantmetal’s FAI process eliminates uncertainty by offering:

– Universal Documentation: Clearly structured reports that translate technical data across geographies

– Dispute Prevention: Early verification reduces shipping issues, customs delays, and rejected shipments

– Trust Building: Demonstrates supplier accountability and commitment to quality

– Standards Alignment: Ensures compliance regardless of where your production is located

Conclusion

At Plantmetal, we treat every first article like it’s the foundation of your product’s success—because it is. Our First Article Inspection process isn’t just a checkbox; it’s a critical investment in your long-term quality, reputation, and bottom line. If you’re ready to take the guesswork out of your next project, let’s connect. Whether you’re developing a new product or scaling an existing one, our team is here to help you launch with confidence—starting from the very first stamped part. Reach out today, and let’s get it right from the start.