Panoramica:

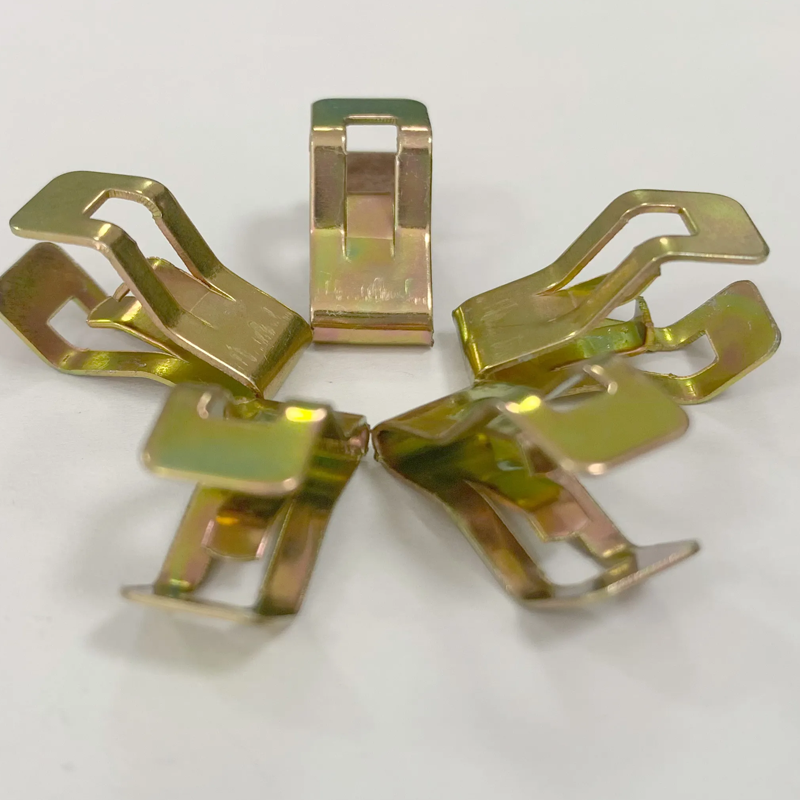

We specialize in the OEM production of precision-engineered stamped steel and stainless-steel clips and fasteners for automotive applications. Manufactured using high-speed progressive die stamping, blanking, bending, and piercing techniques, our components are crafted from premium-grade carbon steel and 301/304 stainless steel to ensure superior strength and performance.Our comprehensive, one-stop manufacturing solution covers everything from custom tool design and rapid prototyping to high-volume production, secondary finishing processes such as electropolishing, passivation, and plating, as well as final kitting and packaging.Whether you require corrosion-resistant stainless-steel clips, heavy-duty steel fasteners, or custom automotive brackets, our end-to-end service guarantees reliable, high-quality parts delivered on time to meet your exact specifications—every time.

Caratteristiche:

| Attributo | Detail |

| Customized Support | OEM |

| Campione | Can be Provided |

| Materiale | Acciaio Inossidabile |

| Logo | Customized Brand Logo |

| Taglia | Personalizzato |

| Pacchetto | Carton + Iron Pallet |

| Certificazione | ISO9001, IATF16949 |

| MOQ | Small Order Can be Provided |

| Tempo di Consegna | 25–30 days |

Opzioni di Trattamento Superficiale:

- Chemical Passivation

A precisely controlled chemical treatment that generates a uniform, inert oxide layer on stainless‑steel surfaces, dramatically improving corrosion resistance and ensuring long‑term durability.

- Doratura Elettrolitica

The meticulous deposition of an ultra‑thin conductive gold film onto substrates, delivering outstanding electrical performance, superior wear resistance, and reliable protection against tarnishing.

- Placcatura Elettrolitica d'Argento

The application of a high‑purity silver coating via electroplating to maximize electrical conductivity, solderability, and reflectivity, while providing moderate corrosion protection.

Nickel Plating (Electrolytic & Electroless)

A versatile nickel‑based coating technique—available as electrolytic or electroless—designed to impart exceptional hardness, abrasion resistance, and corrosion protection across a broad range of substrates.

Assicurazione della Qualità:

Our metal‑stamped OEM clips—available in both steel and stainless steel—are governed by a rigorous, end‑to‑end quality assurance program. We begin by verifying raw materials through optical emission spectroscopy and mechanical property testing. As parts progress, in‑line dimensional checks are performed with a 3D coordinate‑measuring machine (CMM) and an optical comparator, while hardness is gauged on Rockwell testers and microstructure is inspected under metallurgical microscopes. Finished components then undergo salt‑spray corrosion testing per ASTM B117, and their tensile and fatigue characteristics are validated on universal testing machines. All inspection equipment is calibrated to ISO/IEC 17025 standards, and our IATF 16949/ISO 9001‑certified facility provides full PPAP documentation to ensure complete traceability and customer approval.

Mostra della Fabbrica:

Our facility utilizes state-of-the-art manufacturing technology to achieve unparalleled precision and quality. We are equipped with 25 high-performance punch presses (ranging from 25 to 300 tons), precision wire EDM machines, advanced grinding systems, and specialized welding, polishing, and ultrasonic cleaning equipment, ensuring exceptional surface finishes and cleanliness. In addition, we offer a comprehensive range of metal plating solutions, including electroplating, zinc plating, nickel plating, chrome plating, and anodizing. These treatments provide uniform coatings, superior corrosion resistance, and full compliance with industry standards. With fully automated production lines and strict quality control protocols, we proudly maintain ISO 9001 and IATF 16949 certifications, guaranteeing exceptional reliability, precision, and durability in every aspect of our metal stamping manufacturing processes.