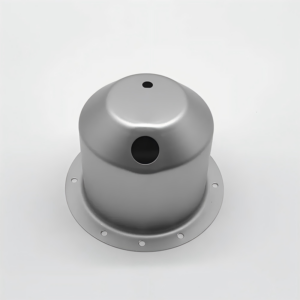

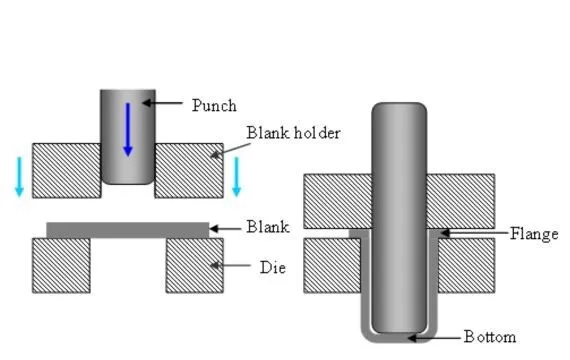

Le lattine ottenute per imbutitura profonda sono contenitori metallici di precisione creati attraverso un processo di imbutitura profonda, in cui una lamiera piana viene progressivamente modellata in una lattina cava senza saldature, stirando il materiale all'interno di una matrice. Realizzate con materiali come acciaio inossidabile, alluminio e ottone, queste lattine sono apprezzate per la loro durata, resistenza alla corrosione e capacità di mantenere l'integrità strutturale in condizioni estreme. Le lattine ottenute per imbutitura profonda trovano ampia applicazione in settori come l'elettronica, l'automotive, il medicale e i beni di consumo, fungendo da involucri protettivi o custodie per componenti sensibili. La loro costruzione senza saldature e la possibilità di personalizzare dimensioni, forma e spessore delle pareti le rendono ideali per applicazioni che richiedono dimensioni precise e standard di elevate prestazioni.

Informazioni di Base

Trattamento Superficiale: Galvanizzazione

Processo di Formatura: Parti Stampate in Metallo

Opzioni di Finitura Superficiale: Nichelatura, Placcatura in Stagno, Placcatura in Zinco

Disponibilità del campione: Disponibile

Tolleranza: ±0,001 mm

Dimensioni: Personalizzabile secondo le esigenze

Applicazione: Industriale, Arredamento, Automobilistico, Motociclistico, ecc.

Approccio di Produzione: Stampaggio Metallico, Taglio, Punzonatura, Piegatura, Saldatura

Imballaggio per il Trasporto: Busta OPP, Scatola o Personalizzato

Specifiche: Personalizzato

Origine: Xiamen, Cina

Vantaggi del nostro prodotto

- Ingegneria di Precisione

Le nostre parti stampate in metallo sono realizzate con alta precisione, garantendo dimensioni esatte e qualità costante per prestazioni ottimali.

- Alta Durata

Utilizzando materiali robusti e tecniche avanzate di stampaggio, i nostri componenti offrono una resistenza e una durata superiori, adatti per applicazioni impegnative.

- Produzione Economica

L'efficienza dei nostri processi di stampaggio riduce al minimo lo spreco di materiale e abbassa i costi di produzione, offrendo soluzioni economiche per la produzione su larga scala.

- Rapida Esecuzione della Produzione

Le nostre apparecchiature all'avanguardia e i processi ottimizzati consentono cicli di produzione rapidi, rispettando scadenze strette e richieste di grandi volumi.

- Applicazioni Versatili

Le nostre parti stampate in metallo sono versatili e possono essere personalizzate per adattarsi a una vasta gamma di settori, tra cui automotive, aerospaziale e applicazioni industriali.

- Qualità Consistente

Rigorose misure di controllo qualità garantiscono che ogni componente soddisfi specifiche rigorose e standard del settore, offrendo prodotti affidabili e coerenti.

- Tecnologia Avanzata

Utilizziamo tecnologie all'avanguardia, come macchine CNC e taglio laser, per ottenere tagli precisi e design intricati con alta efficienza.

- Soluzioni Personalizzabili

Offriamo opzioni di personalizzazione flessibili per soddisfare requisiti di design specifici e necessità funzionali, fornendo soluzioni su misura per progetti diversi.

- Opzioni di Trattamento Superficiale

Una varietà di trattamenti superficiali, tra cui placcatura e ossidazione, sono disponibili per migliorare l'appeal estetico e le prestazioni delle nostre parti stampate in metallo.

- Pratiche Sostenibili

I nostri processi enfatizzano la sostenibilità riducendo gli sprechi e ottimizzando l'uso dei materiali, in linea con pratiche di produzione rispettose dell'ambiente.