Panoramica

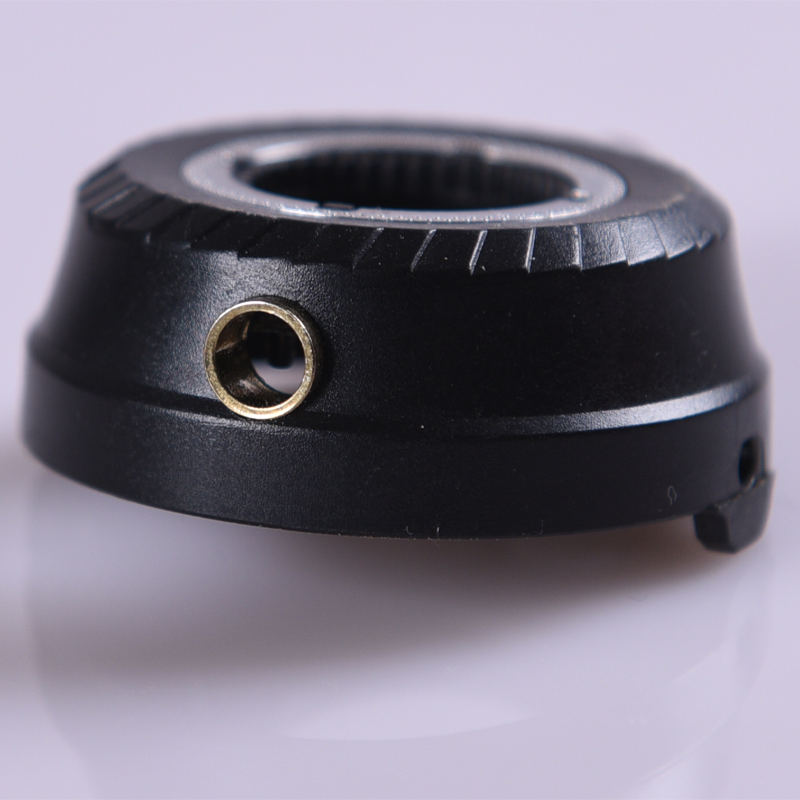

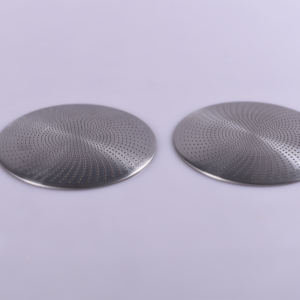

L'involucro auricolare è un componente cruciale delle cuffie, progettato per alloggiare e proteggere le parti interne garantendo al contempo durata e comfort. Realizzato con materiali di alta qualità, questo involucro fornisce un rivestimento esterno sicuro per gli elementi elettronici e acustici delle cuffie. È progettato per un facile assemblaggio e prestazioni di lunga durata, il che lo rende ideale per l'uso in call center professionali, uffici e dispositivi audio personali. L'involucro auricolare garantisce sia una protezione funzionale che un design elegante ed ergonomico per un'esperienza utente ottimizzata.

Il Processo di Produzione per le Nostre Parti Stampate in Metallo:

-

Ricevuta dell'Ordine e Revisione del Disegno

Ricevere e revisionare gli ordini dei clienti, inclusi i disegni tecnici in formati come DXF, IGS, STEP o PDF.

-

Conferma del Design

Confermare i dettagli del design con il cliente per garantire l'accuratezza prima dell'inizio della produzione.

-

Preparazione del Materiale

Seleziona e prepara i fogli di metallo in base alle specifiche richieste.

-

Taglio di Precisione

Utilizzare il taglio laser e la cesoiatura CNC per tagliare lamiere metalliche con dimensioni precise.

-

Formazione e Modellatura

Eseguire piegatura, punzonatura e stampaggio per ottenere le forme e le caratteristiche desiderate.

-

Saldatura e Rivettatura

Unisci componenti metallici utilizzando tecniche avanzate di saldatura e rivettatura.

-

Trattamento Superficiale

Applicare i trattamenti superficiali necessari, inclusi placcatura e spruzzatura, per migliorare la durata e l'aspetto.

-

Assemblaggio e Controllo Qualità

Assemblare i componenti ed eseguire rigorosi controlli di qualità per garantire la conformità alle specifiche.

-

Imballaggio e Spedizione

Imballare le parti finite in modo sicuro e gestire la logistica per una consegna puntuale al cliente.

-

Assistenza Post-Vendita

Fornire supporto continuo e affrontare eventuali problemi post-consegna per garantire la soddisfazione del cliente.

Controllo Qualità

La qualità è la nostra priorità assoluta. All'inizio di ogni progetto, conduciamo uno studio di fattibilità sui componenti metallici per garantirne la producibilità. Eseguiamo inoltre uno studio di "run-at-rate" durante la fase iniziale di produzione per validare la qualità prima di procedere alla produzione su larga scala. Ciò consente ai nostri team di gestione della qualità e della produzione di monitorare attentamente i controlli e garantire operazioni senza intoppi. Una volta completati i test con successo, procediamo con la produzione del primo lotto di componenti metallici conformi.

Il nostro sistema di gestione della qualità si basa su tecnologie e controlli avanzati, iniziative di miglioramento continuo e un laboratorio e un team di qualità all'avanguardia. In tutto il nostro stabilimento di produzione, utilizziamo sistemi di visione con telecamere in linea e fuori linea e tecnologia a sensori, personalizzati per ogni programma di produzione. La nostra tecnologia di visione si integra con i nostri macchinari di stampaggio per ispezionare e verificare meticolosamente le caratteristiche e le dimensioni dei pezzi utilizzando l'imaging automatico con telecamere. Questo rigoroso processo di controllo qualità garantisce che ogni parte metallica prodotta soddisfi i nostri elevati standard, assicurando una qualità del 100% e zero difetti.

Perché Scegliere Noi?

-

Ampia scelta e consegna rapida

Offriamo un'ampia gamma di opzioni e garantiamo una consegna puntuale.

-

Vasta rete di vendita

La nostra consolidata rete di vendita garantisce un'ampia copertura del mercato.

-

Attrezzature e Tecniche di Produzione Avanzate

Utilizziamo attrezzature all'avanguardia e metodi di produzione innovativi.

-

Prezzi competitivi con un servizio eccezionale

Goditi prezzi competitivi uniti al nostro impegno per un eccellente servizio clienti.

-

Here are a few options for translating "Custom Designs Available" to Italian, depending on the nuance you want to convey:

* **Disegni personalizzati disponibili:** This is a literal translation and a good general option.

* **Design personalizzati disponibili:** Uses the English word "design" which is commonly understood in Italian.

* **Progetti personalizzati disponibili:** This translates to "Custom Projects Available" and might be suitable if the designs are more complex.

* **Creazioni personalizzate disponibili:** This translates to "Custom Creations Available" and is a good option for artistic or handcrafted items.

* **Realizziamo progetti su misura:** This translates to "We create custom-made projects" and is more active and implies the service of creating custom designs is offered.

* **Personalizzazioni disponibili:** A shorter option meaning "Customizations Available."

The best option depends on the context. If you're selling t-shirts, "Disegni personalizzati disponibili" or "Design personalizzati disponibili" might be best. If you're selling furniture, "Progetti personalizzati disponibili" or "Realizziamo progetti su misura" could be more appropriate.

Soddisfiamo diverse richieste di design per venire incontro alle specifiche del cliente.

-

Test di qualità rigorosi

Le nostre apparecchiature di collaudo avanzate garantiscono il controllo al 100% delle dimensioni critiche per una qualità superiore.