Breve Introduzione:

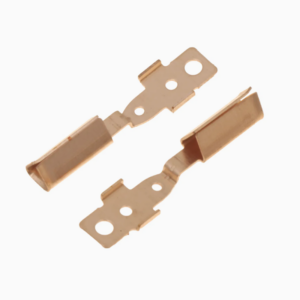

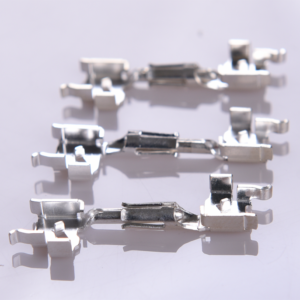

Il terminale connettore a filo stampato in metallo è un componente cruciale progettato per stabilire e garantire connessioni elettriche affidabili in diversi sistemi elettronici ed elettrici. Nel nostro stabilimento, siamo specializzati nella personalizzazione di questi terminali per soddisfare requisiti specifici, assicurando che ogni prodotto sia adattato alle esigenze uniche dei nostri clienti. Grazie a tecniche avanzate di stampaggio del metallo, i nostri macchinari all'avanguardia modellano con precisione le lamiere metalliche nella configurazione esatta del terminale richiesto. Questo processo garantisce una produzione accurata e uniforme, migliorando le prestazioni e l'affidabilità delle connessioni elettriche. Ogni terminale soddisfa rigorosi standard di qualità, offrendo soluzioni personalizzate e affidabili per un’ampia gamma di applicazioni.

Processo di Produzione del Terminale del Connettore:

- Selezione dei Materiali: Scegli con cura materiali di alta qualità che offrano conducibilità e durata ottimali.

- Lavorazione di Precisione: Utilizzare tecniche di lavorazione all'avanguardia per ottenere dimensioni e tolleranze precise.

- Trattamento Superficiale: Applicare rivestimenti o placcature specializzate per migliorare la resistenza alla corrosione e la conduttività.

- Assembly: Expertly assemble the components to form the complete connector terminal.

- Controllo Qualità: Eseguire test e ispezioni rigorosi per garantire prestazioni e affidabilità superiori.

- Imballaggio: Imballare i terminali in modo sicuro per proteggerli durante il trasporto e lo stoccaggio.

Vantaggi dei Terminali a Connettore:

- Affidabilità: I terminali dei connettori offrono una connessione elettrica sicura e costante, garantendo un rischio minimo di perdita o interruzione del segnale. Questa affidabilità è fondamentale nelle applicazioni in cui la trasmissione continua di energia o dati è essenziale.

- Facilità di Manutenzione: Progettati per un'installazione e una rimozione semplici, i terminali dei connettori facilitano una manutenzione e una risoluzione dei problemi efficienti. Questa facilità di accesso riduce i tempi di inattività e i costi di manutenzione, consentendo riparazioni e aggiornamenti più rapidi.

- Versatilità: I terminali dei connettori sono disponibili in diversi tipi e configurazioni, rendendoli adatti a una vasta gamma di applicazioni in diversi settori. La loro adattabilità consente l'utilizzo in tutto, dall'elettronica di consumo all'industria automobilistica e ai macchinari industriali.

- Robustezza: Progettati per resistere a condizioni ambientali difficili, molti terminali dei connettori sono realizzati con materiali che resistono alla corrosione, all'umidità e alle temperature estreme. Questa durabilità migliora le loro prestazioni e la loro durata in ambienti impegnativi.

- Sicurezza Migliorata: I terminali dei connettori progettati correttamente migliorano la sicurezza riducendo al minimo...

Perché Scegliere Noi?

Ampia Competenza nel Settore: Con oltre 20 anni di esperienza, offriamo conoscenze e competenze senza pari a ogni progetto.

Tecnologia all'Avanguardia: La nostra struttura è dotata di macchinari e tecnologie all'avanguardia per garantire qualità e precisione superiori.

– Certified Quality Management: Our operations adhere to certified management systems, guaranteeing consistent quality and reliability.

– Rapid Prototyping Services: Our MYD Rapid Prototyping service accelerates the development process, bringing your ideas to life swiftly.

Servizi di Prototipazione Rapida: Il nostro servizio di Prototipazione Rapida MYD accelera il processo di sviluppo, dando vita alle tue idee in modo rapido.

Supporto Post-Vendita Eccezionale: Offriamo un supporto post-vendita straordinario, garantendo la vostra soddisfazione e affrontando tempestivamente qualsiasi problema.