Descrizione:

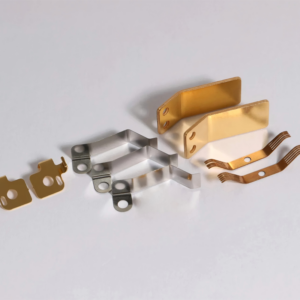

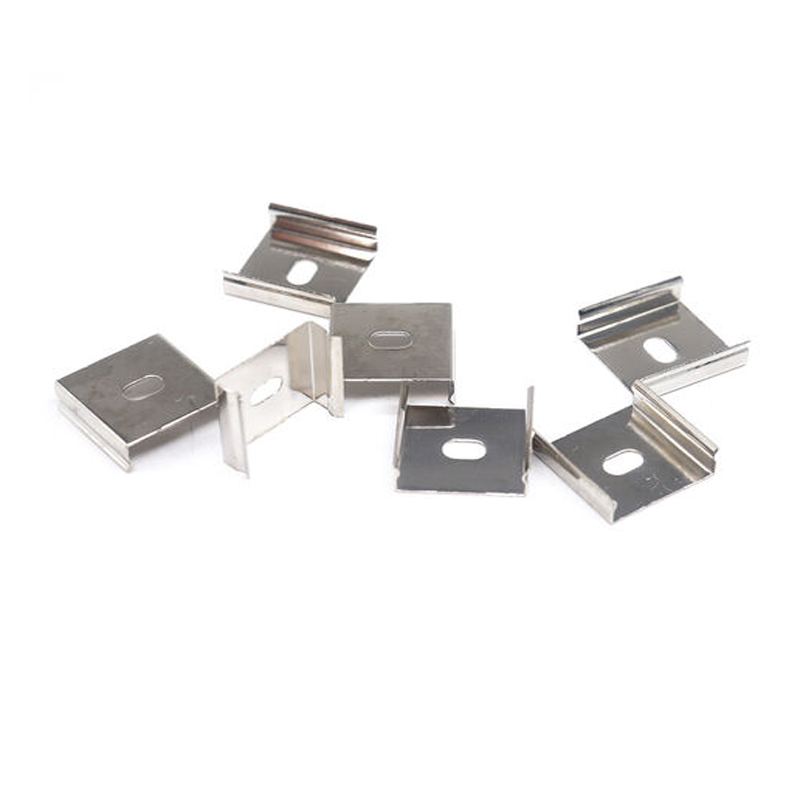

La staffa in metallo in acciaio inossidabile realizzata tramite stampaggio si riferisce a un componente metallico di precisione comunemente utilizzato in una varietà di applicazioni industriali e commerciali. Queste staffe vengono principalmente prodotte mediante processi di stampaggio del metallo, in cui fogli di acciaio inossidabile vengono inseriti in una macchina per stampaggio, che applica pressione per tagliare, piegare e modellare il materiale nella forma desiderata della staffa. Questo processo garantisce un'elevata precisione e uniformità per ogni pezzo. Le nostre staffe metalliche personalizzate sono progettate per soddisfare anche i requisiti applicativi più esigenti, offrendo flessibilità nella scelta dei materiali, inclusi l'acciaio inossidabile, oltre a varie finiture e opzioni di design. Queste caratteristiche rendono le nostre staffe metalliche adatte a una vasta gamma di applicazioni, dai sistemi automobilistici a quelli industriali, garantendo superiore resistenza, durata e affidabilità. Che abbiate bisogno di soluzioni standard o personalizzate, le nostre staffe metalliche offrono prestazioni eccezionali, adattate alle vostre specifiche esigenze.

Caratteristiche:

| Specifica | Dettagli |

| Materiale | Acciaio Inox 304, 316, 202, 201, 430; Alluminio 6061, 6062, 5052; Ottone; Rame; Acciaio Laminato a Freddo; Acciaio Laminato a Caldo |

| Dimensioni | Personalizzabile, in base ai requisiti del cliente |

| Spessore | 0.4 mm to 20.0 mm |

| Tolleranza | ±0,2 mm; Ispezione QC al 100% prima della consegna; Rapporto di ispezione della qualità disponibile su richiesta |

| Elaborazione | Stampaggio, Lavorazione meccanica, Taglio laser, Piegatura CNC, Saldatura, Rivettatura, Sviluppo di stampi/matrici, ecc. |

| Trattamento Superficiale | Verniciatura a polvere, Verniciatura, Sabbiatura, Lucidatura, Zincatura elettrica, Zincatura chimica, Cromatura, Nichelatura, Burattatura, Passivazione, ecc. |

| Formato di Disegno | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, Draft |

| Certificati del Sistema di Qualità | ISO 9001, SGS, IATF16949 |

Processo di Test di Qualità:

Il nostro processo di controllo qualità per la pressofusione di staffe metalliche in acciaio inossidabile garantisce che ogni componente soddisfi i più alti standard del settore. Questo include l'analisi chimica per verificare la composizione del materiale, i test delle proprietà meccaniche per valutare resistenza e durata, e i test d'impatto per analizzare le prestazioni sotto stress. Effettuiamo anche test di pressione per garantire una funzionalità affidabile, oltre a misurazioni tridimensionali (CMM) per confermare dimensioni precise. Inoltre, il nostro processo di garanzia della qualità comprende l'analisi metallografica, l'ispezione con particelle magnetiche per rilevare difetti interni e altri metodi di test avanzati. Ogni prodotto è sottoposto a un'ispezione QC al 100% prima della consegna e, su richiesta, forniamo rapporti dettagliati di ispezione della qualità, assicurando totale trasparenza e fiducia nelle prestazioni dei nostri prodotti.

Trattamenti Superficiali per Staffe in Acciaio Inox:

Verniciatura a polvere: Fornisce una finitura resistente e di alta qualità con eccellente resistenza alla corrosione.

Pallinatura: Migliora la texture superficiale e prepara il metallo per ulteriori trattamenti.

Lucidatura: Ottiene una superficie liscia e lucida per un aspetto estetico e una maggiore resistenza alla corrosione.

Zincatura Elettrica: Offre un rivestimento protettivo di zinco per prevenire ruggine e corrosione.

Zincatura Chimica: Fornisce un rivestimento uniforme per una maggiore resistenza alla corrosione in ambienti difficili.

Cromatura: Offre una finitura elegante e resistente alla corrosione per una maggiore durabilità ed estetica.

Mostra della Fabbrica: