Panoramica:

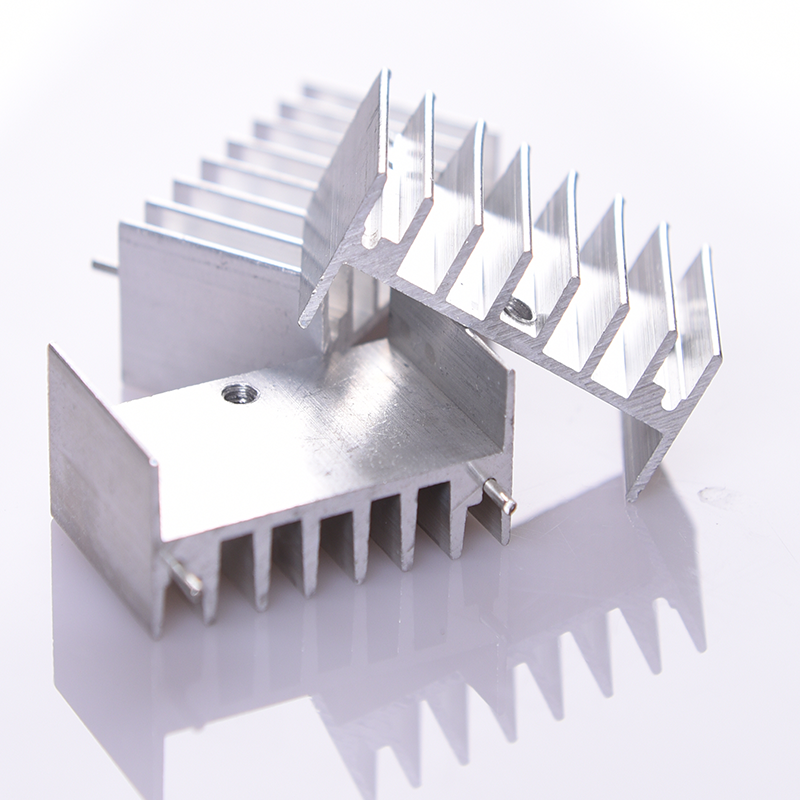

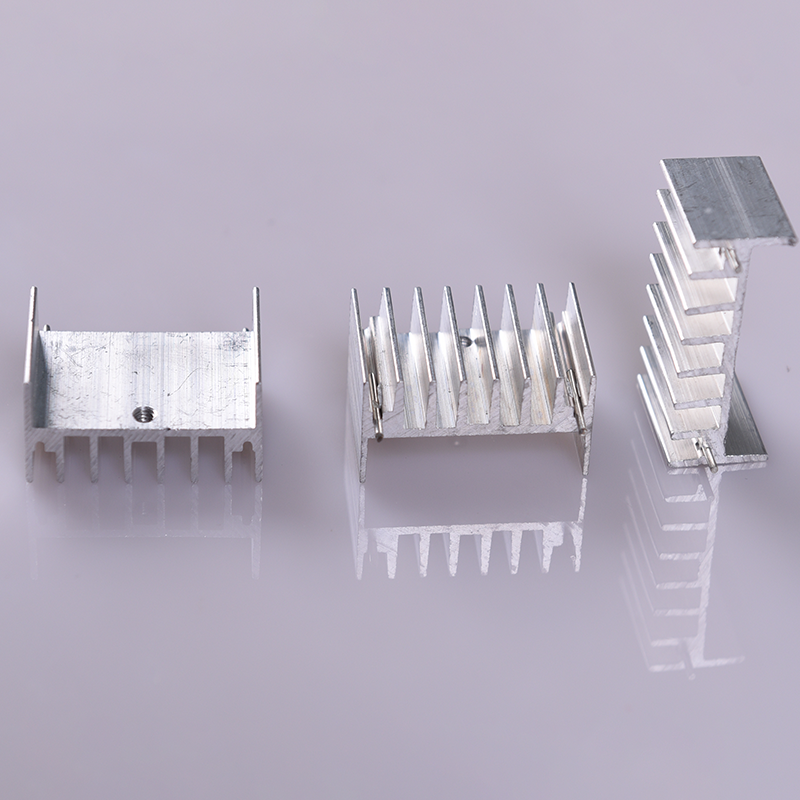

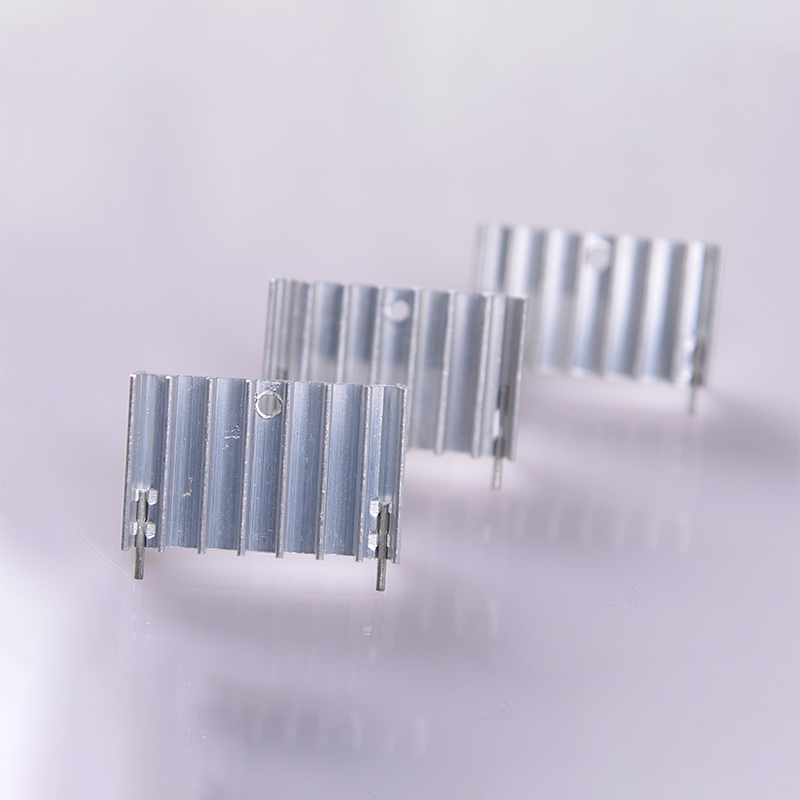

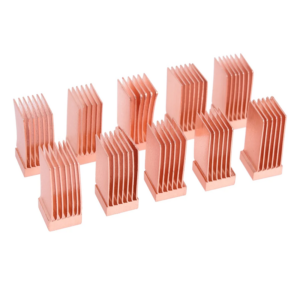

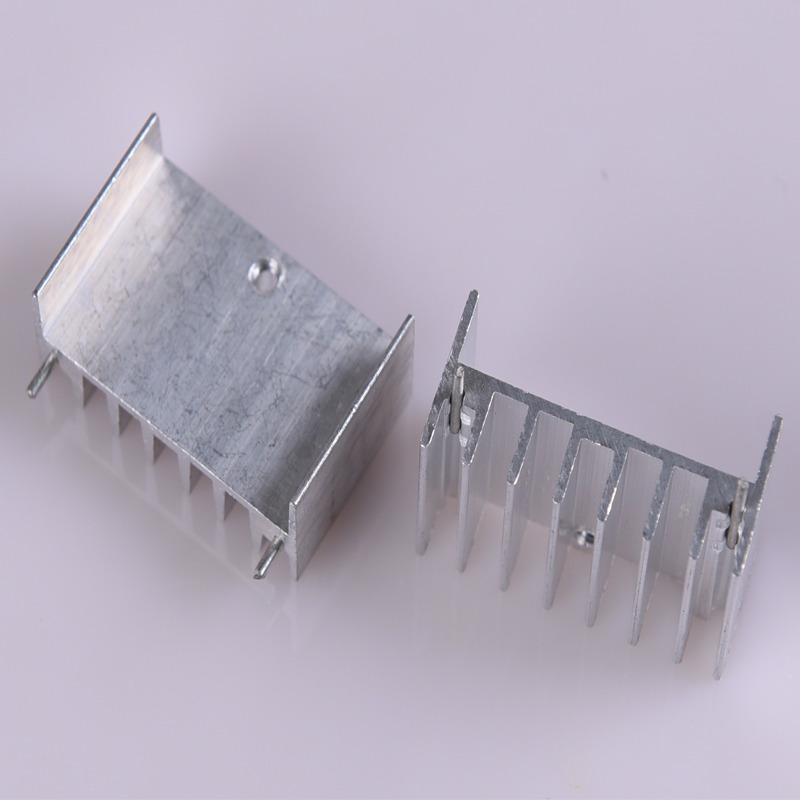

Un dissipatore stampato per applicazioni informatiche è una soluzione essenziale per la gestione termica, prodotto tramite tecniche avanzate come estrusione, pressofusione o lavorazione di precisione. Realizzati con materiali ad alta conduttività come alluminio o rame, questi dissipatori sono progettati per dissipare efficacemente il calore, prevenendo il sovraccarico termico e garantendo prestazioni e durata ottimali per CPU e GPU. Offriamo anche servizi OEM, fornendo soluzioni di gestione termica personalizzate progettate per soddisfare le vostre esigenze specifiche e migliorare l'affidabilità e l'efficienza complessive dei vostri sistemi.

Caratteristiche:

| Attributo | Dettagli |

| Luogo di Origine | Xiamen, Cina |

| Tempo di consegna | Entro 7 giorni |

| Applicazione | Dissipazione del calore del computer |

| Forma | Personalizzato |

| Servizi di elaborazione | Piegatura, Srotolamento, Saldatura, Punzonatura, Taglio |

| Materiale | Lega di alluminio |

| Personalizzazione | Personalizzabile |

| Certificazione | ISO9001 / ROHS |

| Servizio | OEM |

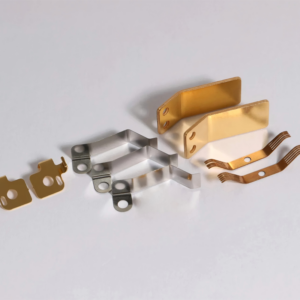

| Colore | Come da immagine; possibilità di personalizzazione. |

Processo di Produzione:

- Scelta dei materiali: I materiali ad alta conduttività, tipicamente alluminio o rame, vengono selezionati in base ai requisiti di gestione termica.

- Taglio: Il materiale scelto viene tagliato nella dimensione e forma richieste, spesso utilizzando il taglio laser o la lavorazione CNC per ottenere dimensioni precise.

- Formatura: A seconda del progetto, il dissipatore di calore viene formato attraverso processi come estrusione, pressofusione, stampaggio o forgiatura per creare la struttura ad alette necessaria per un'efficace dissipazione del calore.

- Trattamento superficiale: Per migliorare la dissipazione del calore e proteggere dalla corrosione, il dissipatore di calore viene sottoposto a trattamenti superficiali come l'anodizzazione o la placcatura.

- Assembly and Finishing: If the heat sink design includes multiple parts, they are assembled, followed by deburring, polishing, or coating as necessary to improve performance and aesthetics.

- Controllo Qualità: Vengono eseguiti test rigorosi per garantire che il dissipatore di calore soddisfi gli standard di conducibilità termica, precisione dimensionale e durata.

- Imballaggio e Spedizione: Una volta approvati, i dissipatori di calore vengono accuratamente imballati e preparati per la distribuzione, garantendo che arrivino in perfette condizioni.

Trattamento superficiale per dissipatore di calore

- Verniciatura a polvere: uno strato protettivo e resistente viene applicato al dissipatore di calore utilizzando polvere elettrostatica, migliorando la resistenza alla corrosione e l'aspetto estetico.

- Sabbiatura: Questo processo irruvidisce la superficie, creando una texture uniforme che aumenta l'area superficiale per una migliore dissipazione del calore e migliora l'adesione dei rivestimenti successivi.

- Verniciatura: Viene applicato uno strato di vernice per fornire ulteriore protezione contro gli agenti atmosferici e migliorare l'aspetto del dissipatore di calore.

- Finitura Grezza: Il dissipatore mantiene la sua finitura metallica naturale dopo la lavorazione, senza ulteriori trattamenti, offrendo un aspetto pulito e lucido.

Ogni trattamento migliora la durata e le prestazioni termiche del dissipatore, offrendo al contempo opzioni di personalizzazione per l'aspetto e la funzionalità.

Mostra della Fabbrica: