Descrizione:

La nostra struttura utilizza macchinari all'avanguardia a quattro e multi-slide, oltre a presse punzonatrici, per produrre telai portacontatti personalizzati in base alle vostre specifiche esigenze. Il nostro team di progettazione esperto collabora a stretto contatto con voi per garantire che tutti i requisiti siano soddisfatti con precisione. In qualità di produttore certificato ISO 9001, ISO 14001 e IATF 16949, ci impegniamo a mantenere i più elevati standard del settore. Per garantire la massima qualità, implementiamo una solida raccolta dati in ogni fase del processo produttivo ed effettuiamo un'ispezione finale approfondita prima della spedizione. Contattateci oggi stesso per scoprire perché la nostra fabbrica è il partner ideale per i vostri progetti di telai portacontatti personalizzati.

Dettagli:

| Articolo | Dettagli |

| Luogo di Origine | Xiamen, Cina |

| Nome del Marchio | OEM |

| Materiale | Acciaio inossidabile, acciaio al carbonio |

| Software di progettazione | UG, PROE, CAD |

| Certificato | ISO 9001:2015 |

| Tolleranza | +/- 0,002 mm – +/- 0,05 mm |

| Processo | Stampatura, Punzonatura |

| Finire | Zincato, Verniciatura a polvere, Verniciatura |

| Colore | Personalizzato |

| MOQ | Si accettano anche piccoli ordini. |

| Imballaggio | Personalizzato |

Processo di Produzione:

-

Selezione dei Materiali

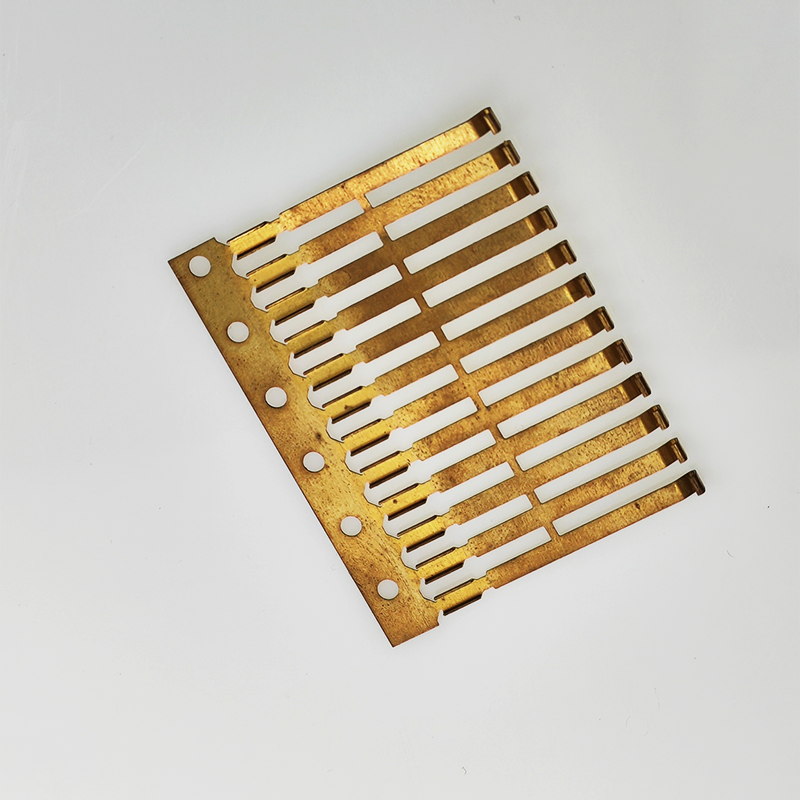

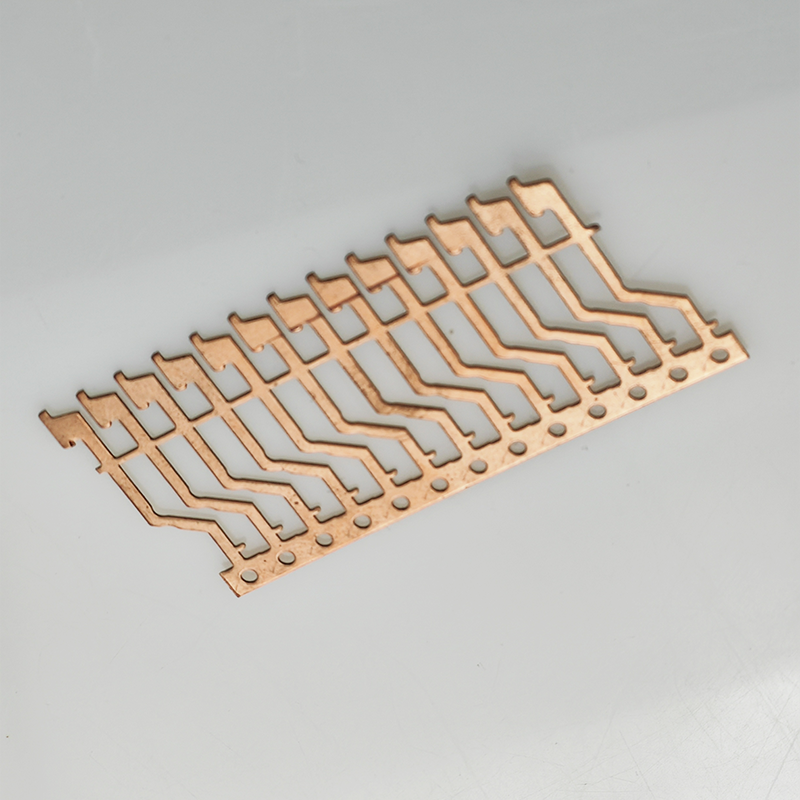

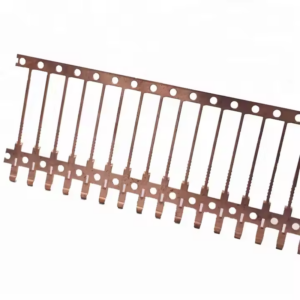

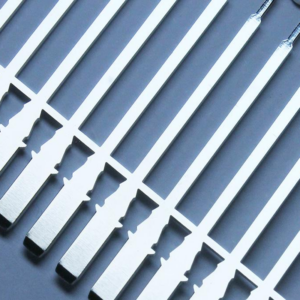

– Materiali utilizzati: Tipicamente realizzati con materiali come acciaio inossidabile, rame o ottone, scelti per la loro conduttività, resistenza alla corrosione e capacità di resistere alle alte temperature.

-

Progettazione e Attrezzature

Progettazione CAD: Il processo di progettazione inizia con software avanzati di progettazione assistita da computer (CAD), come UG, PROE o CAD, per creare specifiche dettagliate per il lead frame.

– Creazione degli Strumenti: Gli stampi di precisione vengono creati utilizzando la lavorazione CNC o l'EDM (Elettroerosione) per formare i lead frame con accuratezza.

-

Stampaggio

Stampaggio Progressivo: Il processo di stampaggio utilizza uno stampo a più stadi per modellare progressivamente il materiale, tagliandolo e formandolo nella forma desiderata del telaio di supporto (lead frame).

Foratura: Potrebbero essere necessarie ulteriori forature per garantire il corretto posizionamento dei fori per i collegamenti dei LED.

-

Trattamento Superficiale

– Galvanoplastia: I frame di piombo vengono placcati con un sottile strato di oro, argento, stagno, nichel, zinco o rame per migliorarne la conduttività e proteggerli dalla corrosione.

Incisione laser: l'incisione laser può essere applicata per realizzare marcature precise o codici di identificazione sul telaio del lead.

-

Ispezione

Controllo Qualità: Durante l'intero processo produttivo, i lead frame sono sottoposti a rigorosi controlli di qualità, che includono la precisione dimensionale, la finitura superficiale e l'adesione del rivestimento. I metodi di ispezione comuni includono la CMM (Macchina di Misurazione a Coordinate) e le ispezioni visive.

-

Montaggio (Se Necessario)

– Assemblaggio: In alcuni casi, i lead frame vengono ulteriormente assemblati in unità complete, pronte per essere utilizzate nel confezionamento di LED o nell'integrazione in dispositivi elettronici.

-

Imballaggio e consegna

– Confezionamento finale: Una volta che i lead frame superano il controllo qualità, vengono confezionati secondo le esigenze del cliente, con opzioni come il confezionamento sottovuoto o confezionamenti personalizzati.

– Consegna: I prodotti finiti vengono quindi consegnati al cliente secondo il programma concordato, spesso con tempi di consegna rapidi per gli ordini urgenti.

Processo di Controllo Qualità:

In Plantmetal, la qualità è la nostra massima priorità. Iniziamo ogni progetto con un'accurata analisi di fattibilità per garantire la producibilità, seguita da uno studio "run-at-rate" sul lotto di produzione iniziale per confermare la qualità prima della produzione su vasta scala. Questo permette ai nostri team di monitorare attentamente la produzione e garantire operazioni senza intoppi.

Utilizziamo sistemi di visione artificiale in linea e fuori linea avanzati e tecnologia a sensori per ispezionare ogni singolo pezzo durante la produzione, garantendo una qualità del 100% e zero difetti. Il nostro sistema di gestione della qualità certificato ISO, supportato da iniziative di miglioramento continuo, assicura che ogni pezzo soddisfi i più elevati standard.

Riconoscendo che la progettazione dei telai portacomponenti richiede specifiche personalizzate, offriamo soluzioni su misura per applicazioni critiche. Con una vasta esperienza nella produzione di telai portacomponenti ad alte prestazioni, Plantmetal è il vostro partner di fiducia per precisione e qualità nella produzione di telai portacomponenti.

La Nostra Fabbrica:

Gestiamo una vasta gamma di impianti e attrezzature per garantire una produzione di altissima qualità. Le nostre strutture sono dotate di 25 presse a punzonatura con capacità che vanno da 25 tonnellate a 300 tonnellate, macchine EDM a filo di precisione, attrezzature per la rettifica, strumenti per saldatura e lucidatura, e sistemi di pulizia a ultrasuoni.

Oltre alle nostre capacità produttive, offriamo una varietà di processi di placcatura dei metalli per migliorare la durabilità, l'aspetto e la funzionalità dei nostri prodotti di stampaggio metallico. Questi includono galvanizzazione, placcatura allo zinco, placcatura al nichel, placcatura al cromo e anodizzazione. I nostri impianti di placcatura all'avanguardia garantiscono finiture uniformi, resistenza alla corrosione e conformità agli standard del settore.

Questa combinazione di linee di produzione professionali e automatizzate, attrezzature meccaniche avanzate, rigorose misure di controllo qualità e processi di placcatura di alta qualità garantisce la consegna di prodotti di stampaggio metallico al massimo standard.