Panoramica:

Nella nostra struttura, siamo specializzati nella produzione di precisione di stampaggi e assemblaggi metallici su misura. Tra la nostra vasta gamma di prodotti, offriamo staffe metalliche personalizzate, progettate e realizzate per soddisfare le specifiche applicative più esigenti. Le nostre soluzioni di staffe metalliche personalizzate comprendono una vasta gamma di opzioni di design, scelte di materiali, finiture superficiali e altre personalizzazioni per garantire prestazioni ottimali in una varietà di applicazioni industriali. Che si tratti di supporto strutturale, montaggio o funzioni specializzate, le nostre staffe metalliche personalizzate sono progettate per superare le aspettative.

Dettagli:

| Attributo | Dettagli |

| Tipo di Stampo | Stampi progressivi multistadio |

| Elaborazione della superficie | Placcatura elettrolitica, Tranciatura fine |

| Tipo di Processo | Processo di Formazione |

| Industria | Parti Stampate in Metallo |

| Tolleranze | ±0.02mm |

| Personalizzazione | Disponibile |

| Lunghezza | 100-1000mm |

| Materiale | Acciaio Inossidabile |

| Tempo di consegna | 7-30 Giorni |

| Capacità di Ricerca e Sviluppo (R&S) | OEM |

| Specifica | Personalizzazione |

| Luogo di Origine | Cina |

Opzioni di Finitura:

- Lucidatura: Ottiene una finitura superficiale liscia e lucida per un aspetto migliorato e una maggiore durata.

- Finitura Naturale: Una superficie di base, non rivestita, ideale per design minimalisti e applicazioni funzionali.

- Sabbiatura: Fornisce una finitura opaca e testurizzata con una rugosità superficiale migliorata, sia per scopi estetici che funzionali.

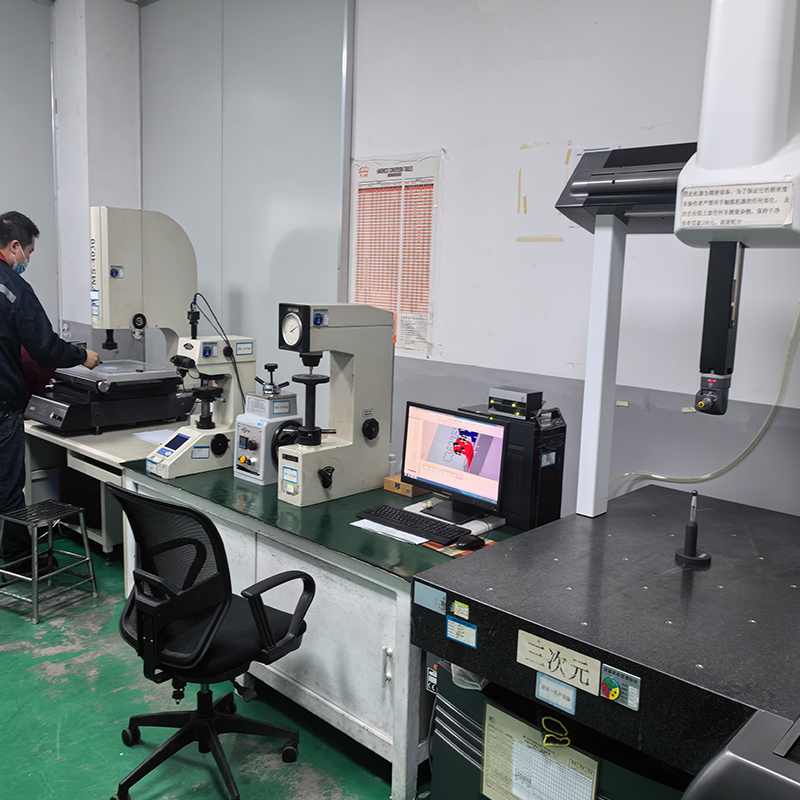

Processo di Test di Qualità:

Il processo di controllo qualità per le staffe in lamiera stampata comprende una serie di rigorose valutazioni per garantire la conformità agli standard del settore. I test principali includono la verifica dimensionale utilizzando strumenti di misurazione ad alta precisione, come calibri e macchine di misura a coordinate (CMM), per confermare l'accuratezza entro tolleranze ristrette. L'integrità della superficie viene controllata tramite ispezioni visive e test come la nebbia salina per la resistenza alla corrosione e la misurazione della rugosità superficiale. Inoltre, le proprietà meccaniche, come resistenza e flessibilità, vengono valutate tramite test di trazione e verifiche della capacità di carico. Infine, vengono eseguiti eventuali test funzionali richiesti, inclusi controlli di adattamento e assemblaggio, per assicurare che le staffe soddisfino i requisiti specificati per l'applicazione.

I nostri servizi:

Ci specializziamo nella produzione di elementi di fissaggio personalizzati per soddisfare le specifiche esatte e i requisiti di prestazione dei clienti.

I nostri dispositivi di fissaggio sono sottoposti a rigorosi test di durata e valutazioni tecniche di progettazione per garantire una maggiore durata del prodotto.

Offriamo prezzi competitivi, fornendo soluzioni convenienti supportate dalle nostre capacità di produzione professionale.

Con oltre 20 anni di esperienza, offriamo una vasta gamma di soluzioni di fissaggio per rispondere efficacemente a qualsiasi esigenza applicativa.

Panoramica della Fabbrica: