At Plantmetal, we understand the critical role that heat management plays in the reliability and performance of electronic devices. Heat sinks, as crucial components of thermal management systems, ensure that your devices remain cool under pressure, avoiding performance degradation and potential failure due to overheating. Whether you are looking to optimize the cooling performance of a high-performance processor, power transistor, or any other electronic system, understanding the underlying principles and types of heat sinks is essential. In this guide, we will walk you through the intricacies of heat sink technology, providing you with a comprehensive overview of their function, types, materials, and manufacturing processes.

What is a Heat Sink?

A heat sink is a device that facilitates the transfer of excess heat from a heat-generating component, such as a microprocessor, power supply, or other electronic devices, into the surrounding environment. Constructed typically from materials with high thermal conductivity, heat sinks are designed with extended surfaces (usually fins) that maximize their ability to dissipate heat. This process involves the principles of conduction, convection, and, in some cases, radiation to enhance heat dissipation. Heat sinks can either rely on natural convection (where heat is passively dissipated through air circulation) or use active cooling mechanisms like fans to improve efficiency.

Why Are Heat Sinks Important?

The primary purpose of a heat sink is to prevent overheating by efficiently transferring heat from sensitive electronic components into the surrounding environment. Heat is an inevitable byproduct of electronic activity, and if not managed properly, it can cause thermal stress, reduce the performance of devices, or lead to permanent damage. Heat sinks prevent these issues by absorbing heat directly from the device, facilitating efficient cooling, and ensuring the device operates within safe temperature limits.

Without proper thermal management, components can overheat, causing a decline in performance, shortened lifespan, or even complete failure of the device. Heat sinks, by ensuring a stable temperature, help maintain high performance and increase the reliability of electronics.

How Do Heat Sinks Work?

The operation of a heat sink begins with its base plate, which makes direct contact with the heat-producing component, such as a microprocessor. This plate absorbs heat through conduction and transfers it to the heat sink’s fins, which significantly increase the surface area for heat dissipation.

The process of natural convection occurs as the heat sink absorbs heat from the component. The surrounding air heats up, becomes less dense, and rises, naturally drawing in cooler air to replace it. This cycle continues to help carry the heat away from the heat sink. However, for applications with higher thermal loads, forced convection is employed. This involves the use of fans or blowers to move air more rapidly over the heat sink, improving its efficiency by speeding up the heat dissipation process.

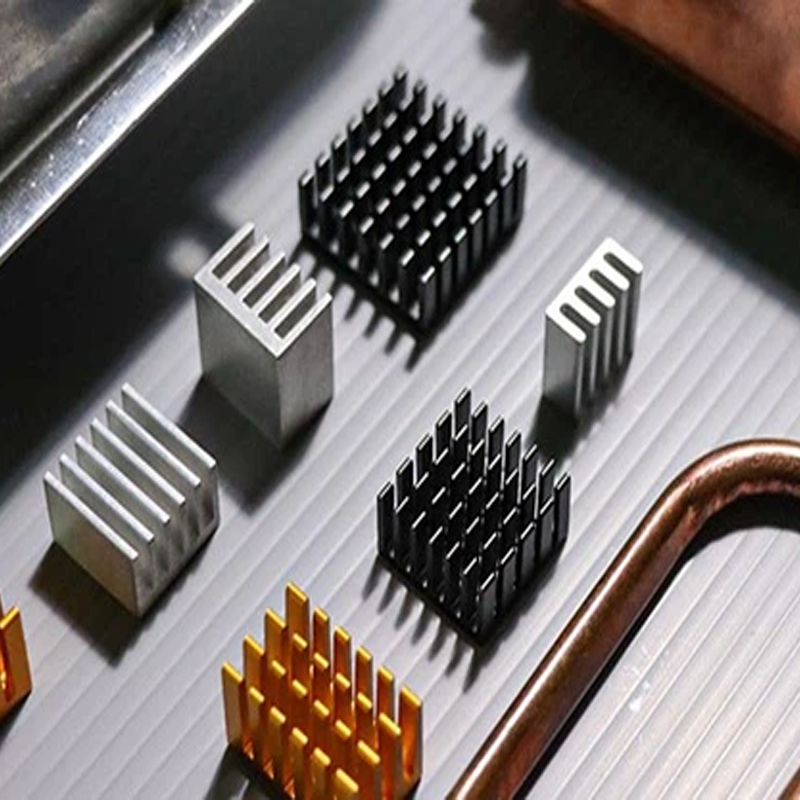

Types of Heat Sinks

Heat sinks come in several varieties, each suited to specific cooling needs. Understanding the differences can help you choose the most appropriate heat sink for your application.

-

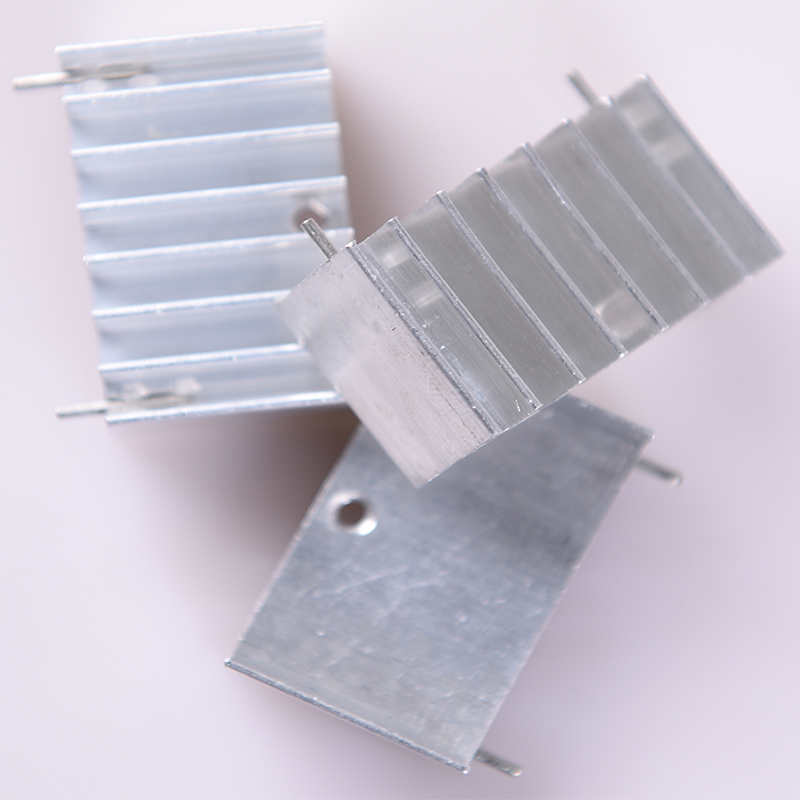

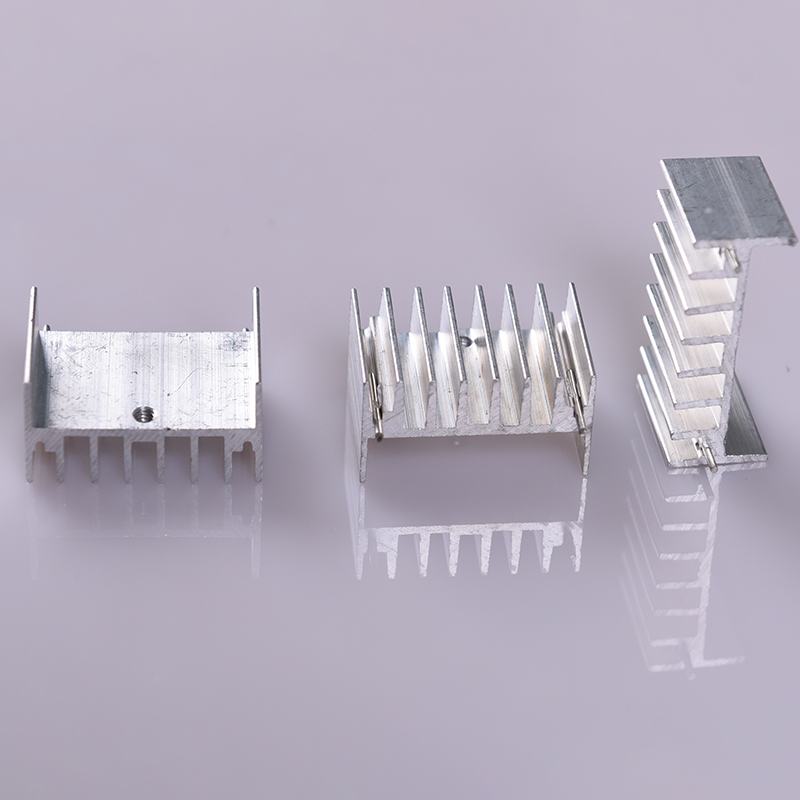

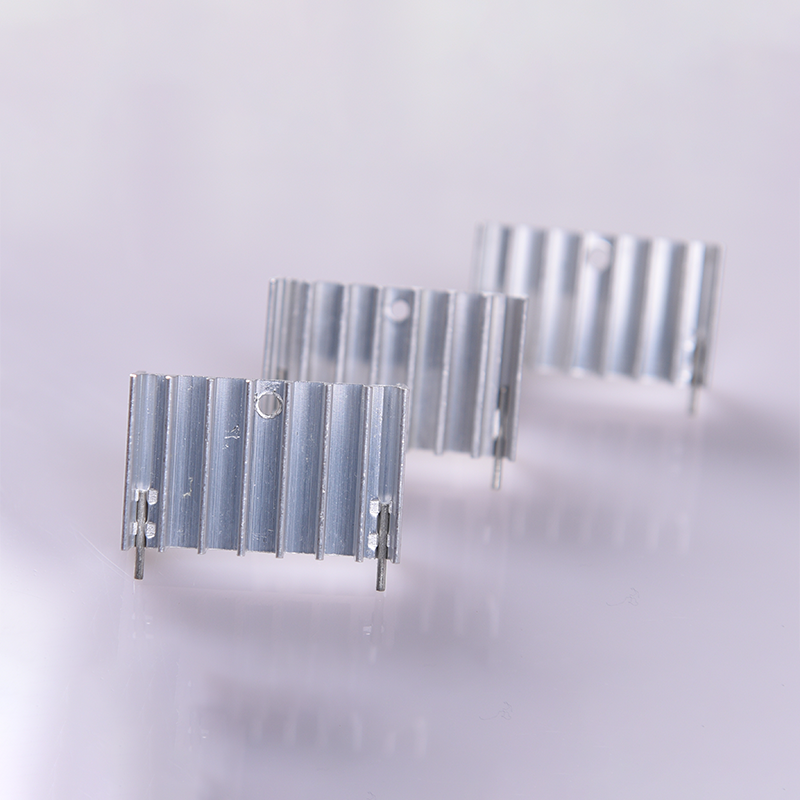

Passive Heat Sinks

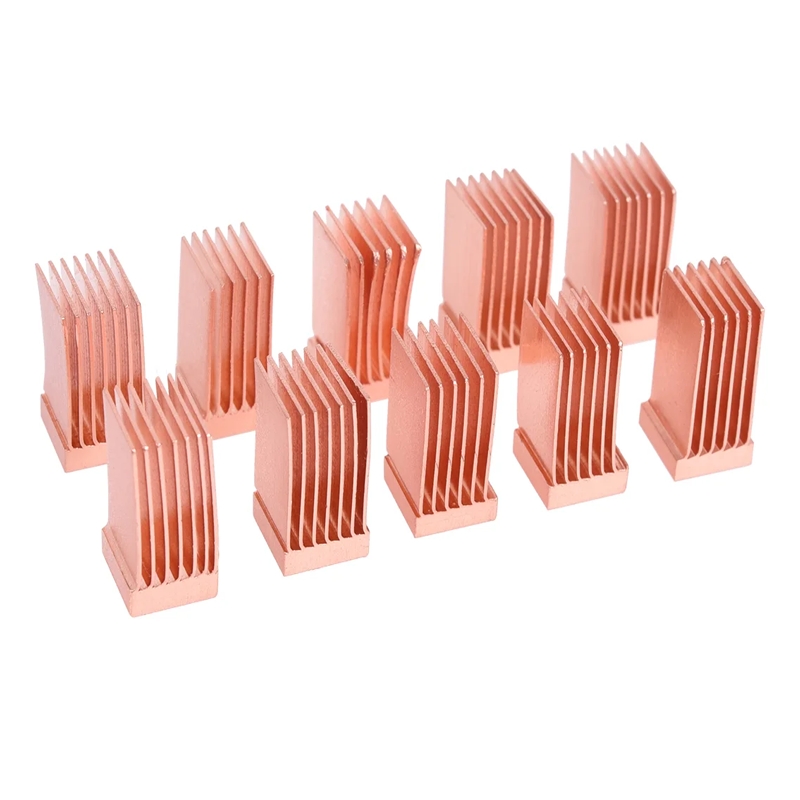

The most basic type of heat sink, passive heat sinks rely solely on natural convection to dissipate heat. They are typically made of aluminum or copper and feature a base plate and several fins. As the heated air rises from the fins, cooler air flows in, helping to carry away the heat. These heat sinks are silent, simple, and cost-effective but are generally limited in their heat dissipation capacity.

-

Active Heat Sinks

Active heat sinks incorporate additional mechanisms such as fans or liquid coolants to accelerate the heat dissipation process. Fans or pumps actively move air or coolant across the heat sink, which significantly enhances cooling efficiency, especially in high-performance applications like gaming systems, servers, or power electronics. Active heat sinks are ideal when higher thermal loads need to be managed.

-

Hybrid Heat Sinks

Hybrid heat sinks combine the benefits of both passive and active cooling. They operate as passive heat sinks under normal conditions but activate an internal fan or pump when the temperature exceeds a predetermined threshold. This provides a quiet operation in moderate conditions and enhanced cooling performance under high thermal loads.

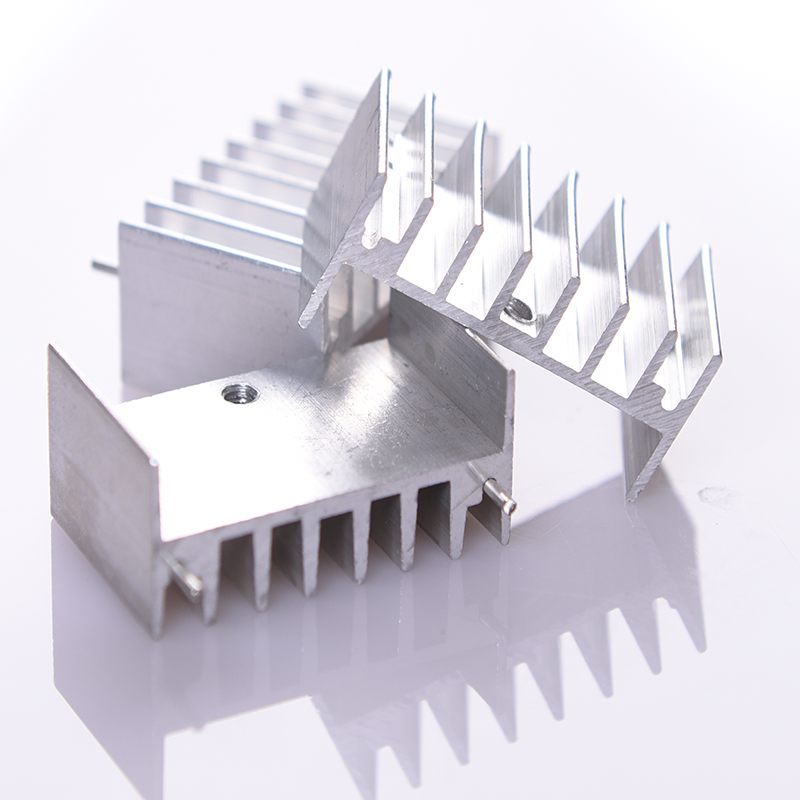

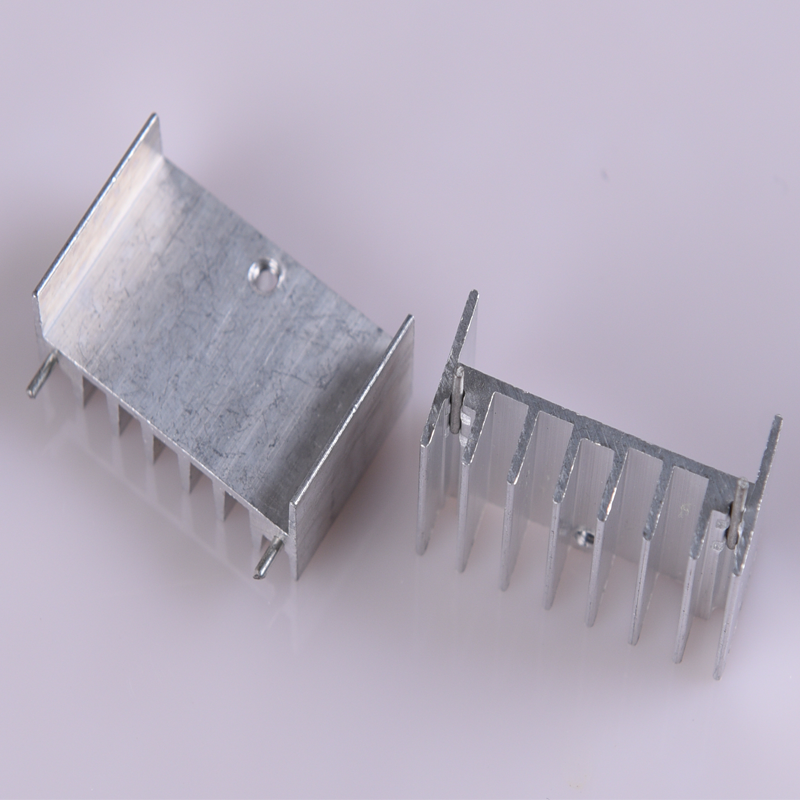

Key Components of a Heat Sink

A heat sink’s design is based on several essential components, each contributing to its efficiency:

– Base Plate: The base plate is the interface between the heat sink and the heat-producing component. Made from materials with high thermal conductivity (such as copper or aluminum), it absorbs heat from the component and distributes it across the heat sink.

– Cooling Fins: These protruding extensions increase the heat sink’s surface area, improving heat dissipation. The arrangement and shape of the fins can vary (e.g., straight, wavy, or louvered) to maximize airflow and enhance the heat exchange process.

– Heat Pipes: Heat pipes are filled with a heat-conductive fluid that vaporizes at one end of the pipe, travels to the cooler end, and condenses, effectively transferring heat away from the heat-generating component.

– Thermal Interface Material (TIM): This layer of material, typically thermal grease or pads, is placed between the heat sink and the component to reduce air gaps and improve thermal conductivity.

Materials Used in Heat Sinks

The materials selected for heat sinks are those that offer optimal thermal conductivity to effectively dissipate heat:

– Aluminum: Lightweight, cost-effective, and offering good thermal conductivity, aluminum is the most commonly used material for heat sinks.

– Copper: Copper has superior thermal conductivity but is heavier and more expensive than aluminum, making it suitable for high-performance applications.

– Graphite and Carbon Materials: These materials offer thermal properties close to copper but are much lighter, making them ideal for weight-sensitive applications.

– Diamond: With the best thermal conductivity, diamond is used in specialized, high-end applications, though its cost and manufacturing complexity limit its widespread use.

Heat Sink Manufacturing Processes

The production of heat sinks involves several manufacturing processes to achieve the desired shape, size, and thermal properties:

– Extrusion: This process involves forcing a heated material through a die to produce a continuous length of heat sink, which is then cut to size. It’s a cost-effective and high-speed process.

– Die Casting: In die casting, molten metal is injected into a mold under high pressure, forming complex shapes and allowing for the creation of detailed heat sink designs.

– Stampaggio: This method uses dies and punches to shape metal sheets into fins or other required patterns, making it ideal for medium to high-volume production.

– CNC Machining: CNC machining allows for the creation of custom-designed, high-precision heat sinks, making it suitable for small to medium production volumes.

– Metal Skiving: Skiving is used to create thin, evenly spaced fins from a solid metal block, optimizing heat dissipation with lightweight designs.

– Metal Forging: This process involves shaping metal with compressive forces, producing heat sinks with robust, high-performance properties ideal for demanding applications.

Conclusion

Heat sinks are integral to the cooling systems of electronic devices, offering a reliable solution to thermal management challenges. At Plantmetal, we specialize in designing and manufacturing high-quality heat sinks tailored to meet your specific thermal management needs. Our expertise in selecting the right materials, designing optimal heat sink geometries, and utilizing advanced manufacturing processes ensures that your devices maintain peak performance, reliability, and longevity.

To learn more about how our custom heat sinks can enhance the efficiency and lifespan of your electronic products, feel free to reach out to us at Plantmetal. Let us help you keep your devices cool and running smoothly!