Deep Drawing Metal Stampings

Precision Stainless Steel Passivation Deep Drawing Metal Stampings Manufacturers

Stainless Steel passivation deep drawing metal Stampings are precision-engineered parts, such as bushings,housings, and shields etc,made using the deep drawing process. This method ensures high strength, uniform thickness, and the ability to create complex shapes with minimal waste. Passivation enhances corrosion resistance, making these parts durable and reliable for demanding applications.

We offer OEM services with customizable sizes, surface treatments, and designs for a variety of industries, including automotive, electronics, and aerospace. Reach us for high-quality, durable deep drawing stampings tailored to your needs.

Our Manufacturing Capabilities

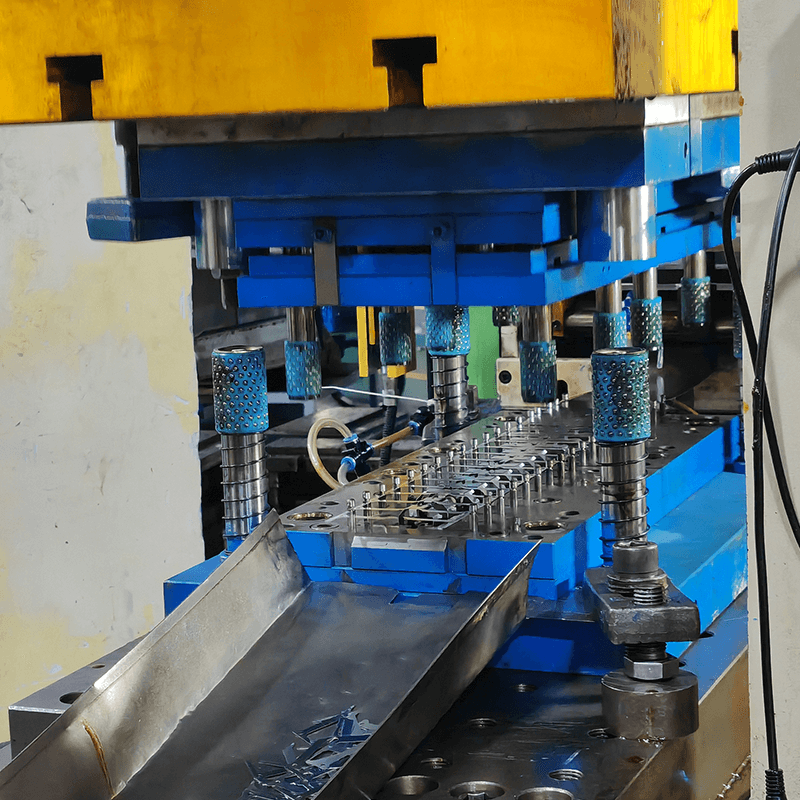

Progressive Metal Stamping

Progressive metal stamping is a precise sheet metal fabrication process that utilizes specialized stamping equipment to sequentially shape or separate metal sheets through a series of dies. This method allows for efficient production of high-quality, complex metal parts with tight tolerances and minimal waste.

Deep Drawing

Deep drawing offers high precision, tight tolerances, and an efficient process for manufacturing custom metal parts with complex shapes. It is ideal for creating high-quality, durable components across various industries.

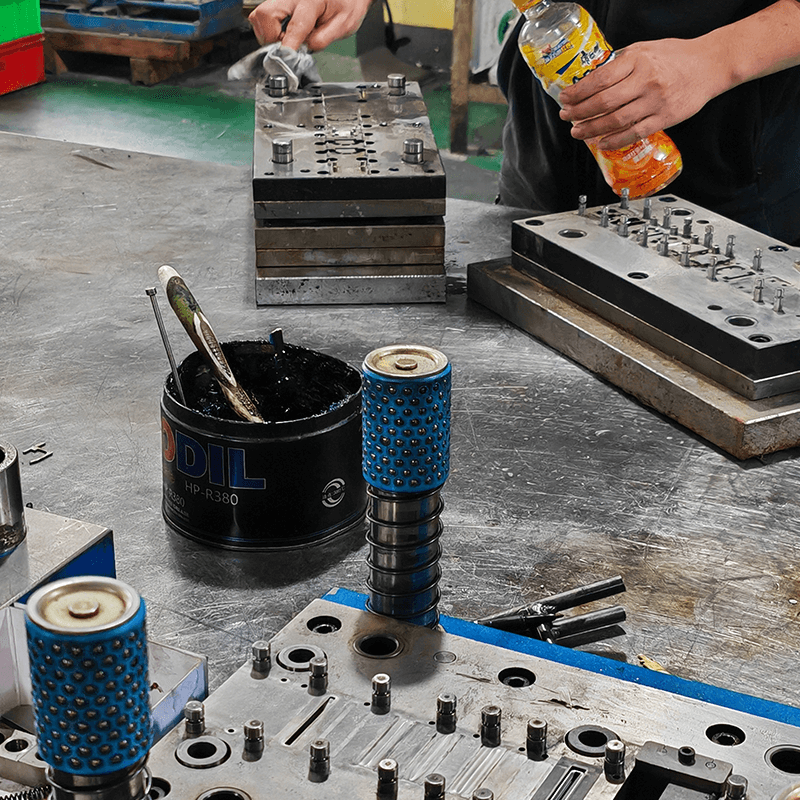

Tool & Die Manufacturing

Tool & die manufacturing is a precision process that shapes raw materials using custom tools and dies, enabling efficient production of high-quality metal components. The quality of the tools and dies is essential for accuracy and durability. This guide offers key insights to help you understand your custom metal needs and select the right tool & die suppliers.

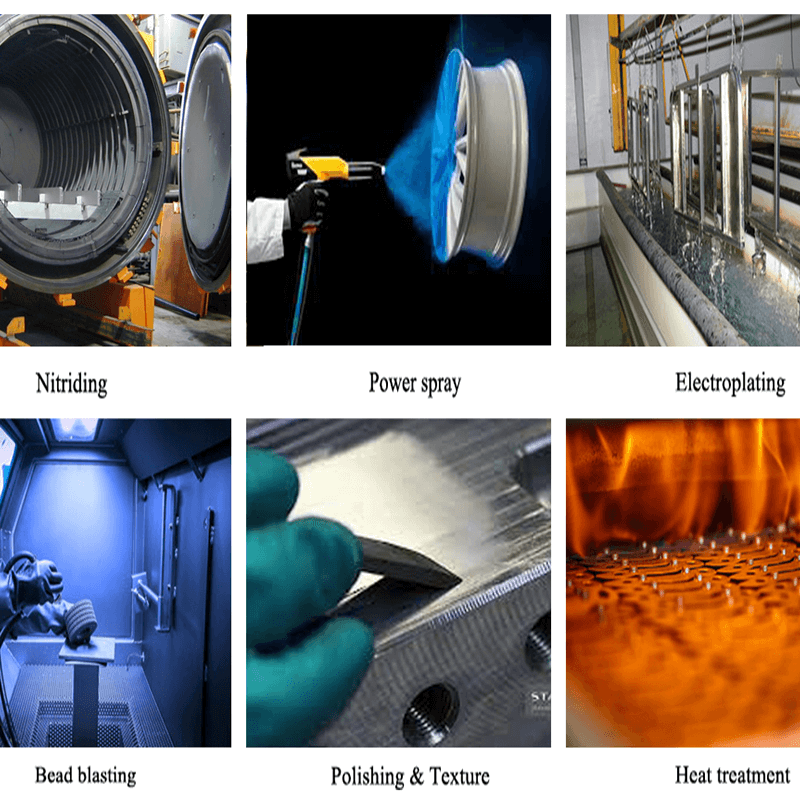

Secondary Processes

We provide a wide range of secondary processes, including nickel plating, silver plating, heat treating, and electropolishing, to deliver the final touches your metal components require. Our one-stop solution ensures each part meets our strict quality standards.

Basic Information

| Attribute | Details |

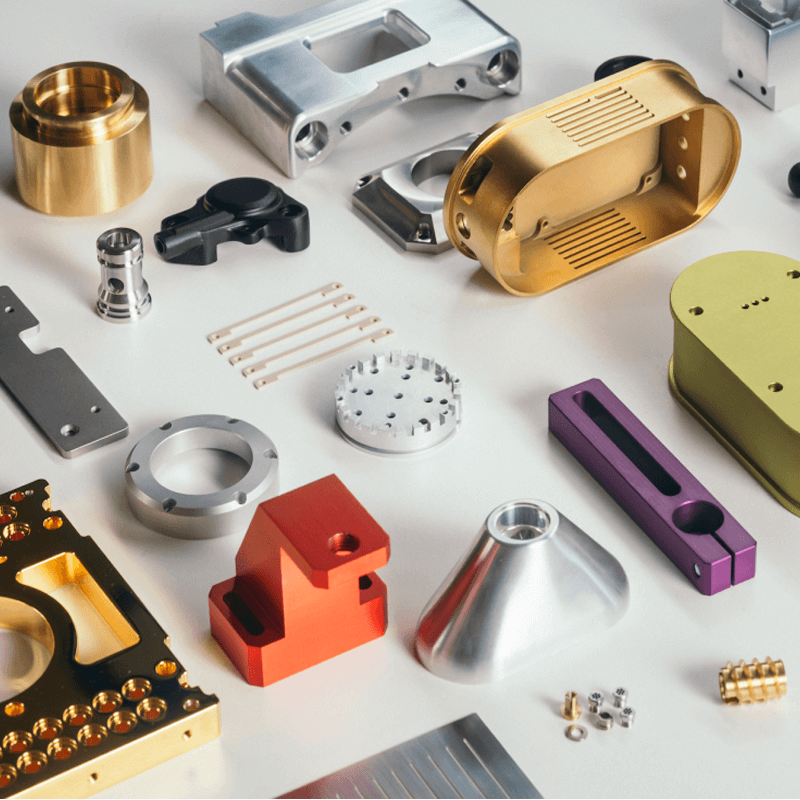

| Material | Aluminum, Stainless Steel, Brass, Copper |

| Mould | Multistep Progressive Dies |

| Process | Deep Drawing |

| Tolerances | 0.01mm |

| Customized | Warmly Welcomed |

| Quality | 100% Inspection Before Shipping |

| Lead Time | 2-4 weeks |

| Shipping Way | By Sea; By Air; By Express |

| Transport Package | To be specified (e.g., Blister, Poly Bag, Foam) |

| Certification | ISO9001, IATF16949 |

| Production Capacity | 2,000,000 PCS Per Month |

Advantages of Our Deep Drawing Metal Stampings

1. Cost-Effective Manufacturing

2 . Fast Production Lead Times

3. Broad Industry Applications

4.Reliable Quality Assurance

OEM Services From Us

1. NDA Agreement

2. 3D Drawing Confirmation

3. DFM Confirmation

4. Prototyping

5. Trial Tooling

6. Mass Tooling

7. Metal Stamping Production

8. QC Inspection & Packaging

9. Warehouse and Logistics

10. After-Sales Service

Surface Finishing Options

Our factory provides various surface finishes, including passivation, anodization, nickel plating, and tin plating, to improve the durability and performance of our products.

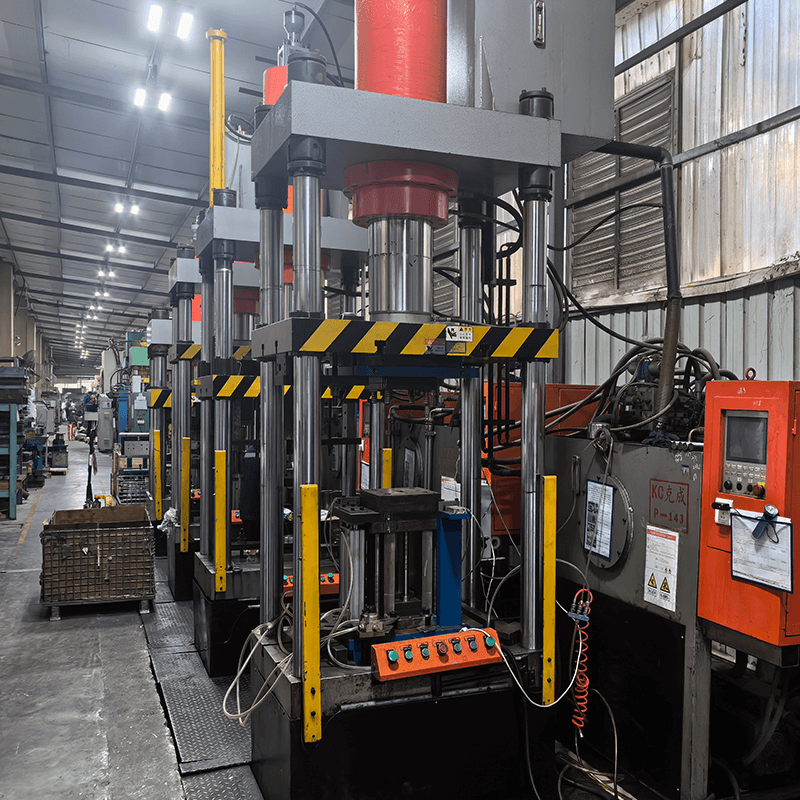

Our Factory

Our facility is equipped with advanced equipment, including 25 punch presses (25 to 300 tons), precision wire EDM machines, grinding tools, and ultrasonic cleaning systems, ensuring top-quality production.

We offer a range of metal plating options, such as electroplating, zinc plating, nickel plating, chrome plating, and anodizing, to enhance product durability and functionality.

Our rigorous quality control includes chemical analysis, mechanical testing, impact and pressure tests, 3D CMM, metallography, and magnetic particle inspections. We are certified to ISO9001 and IATF16949 standards, guaranteeing consistent quality and compliance.

Custom Products Display

Application Industries

Deep drawing metal stampings are integral to producing durable, high-precision components across a wide range of industries. Their versatility and structural reliability make them indispensable in various advanced applications.

- Automotive

- Electronics

- Medical

- Aerospace

- Energy

- Industrial