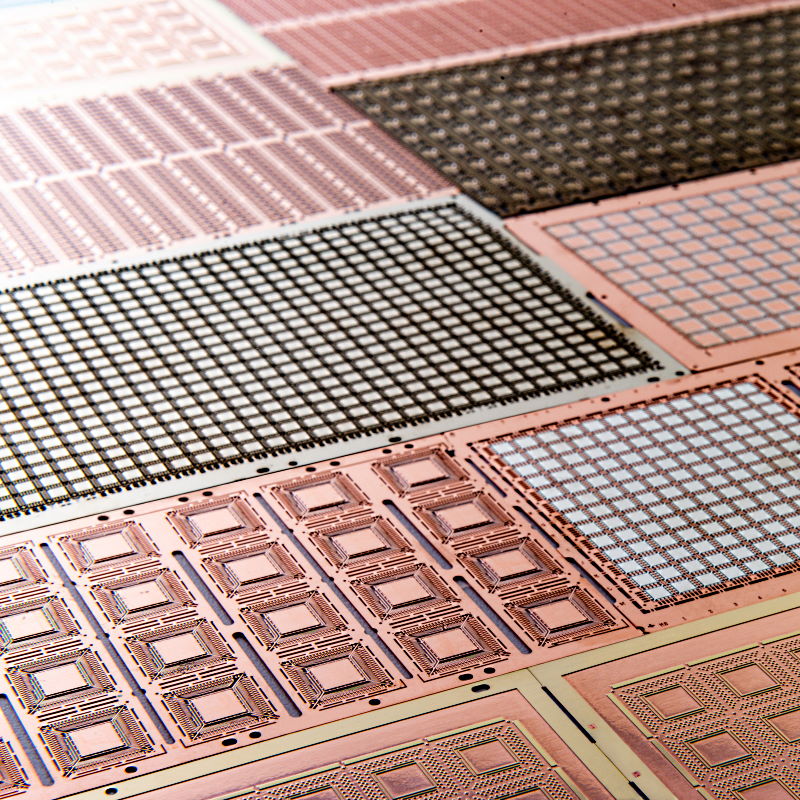

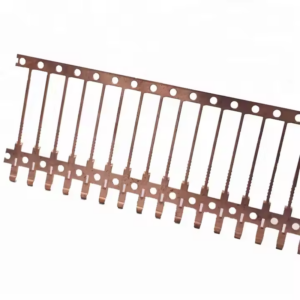

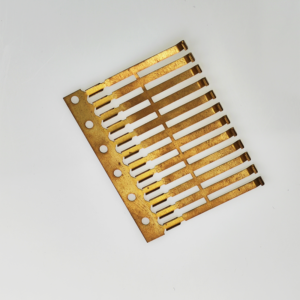

A Lead Frame is a critical component in semiconductor packaging, serving as the conductive pathway for electrical signals between the semiconductor chip and external circuitry. Typically made from materials like copper, nickel, or alloy metals, the lead frame undergoes precise metal stamping, cutting, and plating processes to ensure durability and conductivity. Used in various electronic devices, including automotive, consumer electronics, and industrial applications, lead frames provide structural support and electrical connections in integrated circuits (ICs) and other components. Custom lead frame designs can be tailored to meet specific performance requirements.

Basic Information

Place of Origin: Xiamen, China

Brand Name: OEM

Material :Stainless Steel/ Metal

Type :Hardware Parts

Size: Customized Size

Surface treatment :Galvenized/ Custom

Certificate :ISO9001:2015/IATF16949

Delivery :by sea/air/express

Service Customized: OEM

Application :Industrial

Surface Treatments for Metal Stamping Parts

- Electroplating

– Description: A process that deposits a layer of metal onto the surface of the part using an electric current. Commonly used for improving corrosion resistance and enhancing appearance.

– Types: Nickel plating, chrome plating, zinc plating.

- Powder Coating

– Description: A dry coating process where powdered paint is electrostatically applied and then cured under heat. It provides a durable, high-quality finish with excellent resistance to scratches, chipping, and fading.

- Anodizing

– Description: An electrochemical process that converts the surface of aluminum into a durable, corrosion-resistant layer. Anodizing also enhances appearance and can be dyed in various colors.

- Plating

– Description: The application of a thin layer of metal to the surface of the part to improve wear resistance, reduce friction, or provide an aesthetic finish.

– Types: Tin plating, copper plating.

- Spraying

– Description: A method where paint or protective coating is sprayed onto the part’s surface. This process is used for both aesthetic and protective purposes, offering a wide range of colors and finishes.

- Oxidation

– Description: A chemical treatment that forms a protective oxide layer on the surface of metals, such as steel. It improves corrosion resistance and can provide a unique aesthetic finish.

- Polishing

– Description: A mechanical process that smooths and shines the surface of the part. Polishing removes imperfections and enhances the visual appeal of the metal.

- Sandblasting

– Description: A process that uses high-speed abrasive particles to clean or roughen the surface. It prepares the surface for further treatments or provides a textured finish.

- Passivation

– Description: A treatment process that enhances the natural oxide layer on stainless steel to improve corrosion resistance. It involves soaking the part in a solution that removes free iron and other contaminants.