Overview:

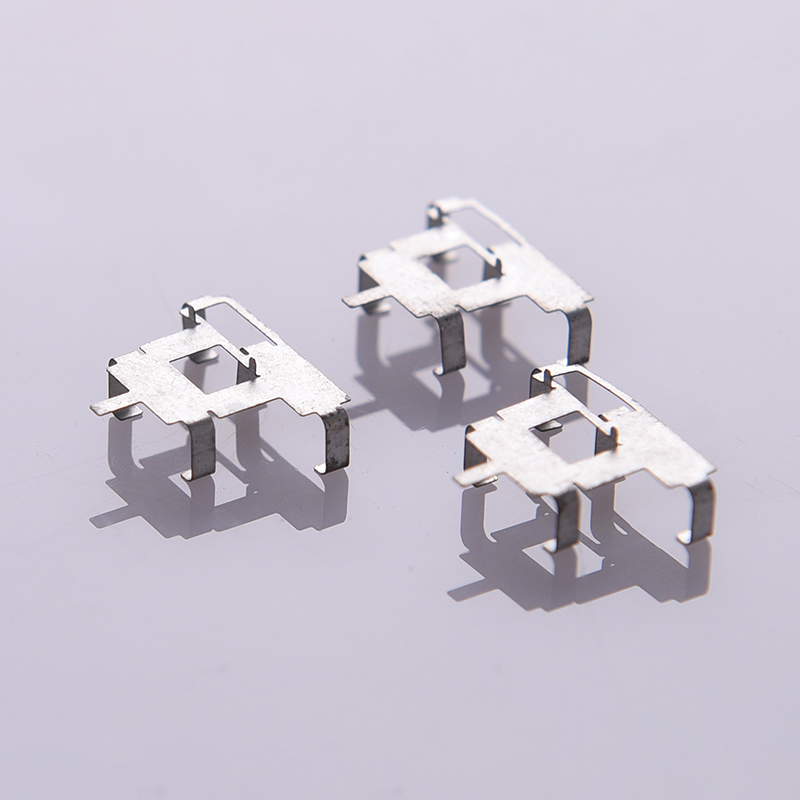

Metal stamped contacts for LED circuit boards are precision-engineered components designed to ensure reliable electrical connections in LED systems. Manufactured using advanced stamping techniques, these contacts are crafted from high-quality materials to meet strict performance standards. With state-of-the-art equipment and expertise, we specialize in producing custom designs tailored to diverse customer requirements. Our OEM services offer flexible solutions to meet various specifications, ensuring optimal functionality and compatibility for your LED applications.

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Custom |

| Color | Custom |

| Standard | ROHS, ISO |

| Certificate | ISO9001, IATF16949 |

| Material | Brass, Copper |

| Processing | Stamping, Drawing, CNC Machining |

| Surface Treatment | Chromium, Polishing, Painting, etc. |

| Service | OEM Accepted |

| MOQ | Small orders can be accepted |

| Quality Control | 100% Inspection before shipment |

| Shipping | Sea / Air / Courier |

Surface Treatment Options:

- Gold Plating: Provides excellent conductivity, corrosion resistance, and durability, ideal for high-performance applications.

- Silver Plating: Offers superior electrical conductivity and thermal performance, suitable for demanding environments.

- Nickel Plating: Ensures enhanced hardness, wear resistance, and corrosion protection, often used as a base layer for additional coatings.

- Tin Plating: Delivers reliable solderability, oxidation resistance, and cost-effectiveness for electrical connections.

Production Process:

-

Material Selection

High-quality conductive materials such as brass or copper are selected based on the design specifications and application requirements.

-

Die Design and Fabrication

Precision stamping dies are designed and fabricated using advanced CNC machining and wire EDM technology to ensure accurate dimensions and tolerances.

-

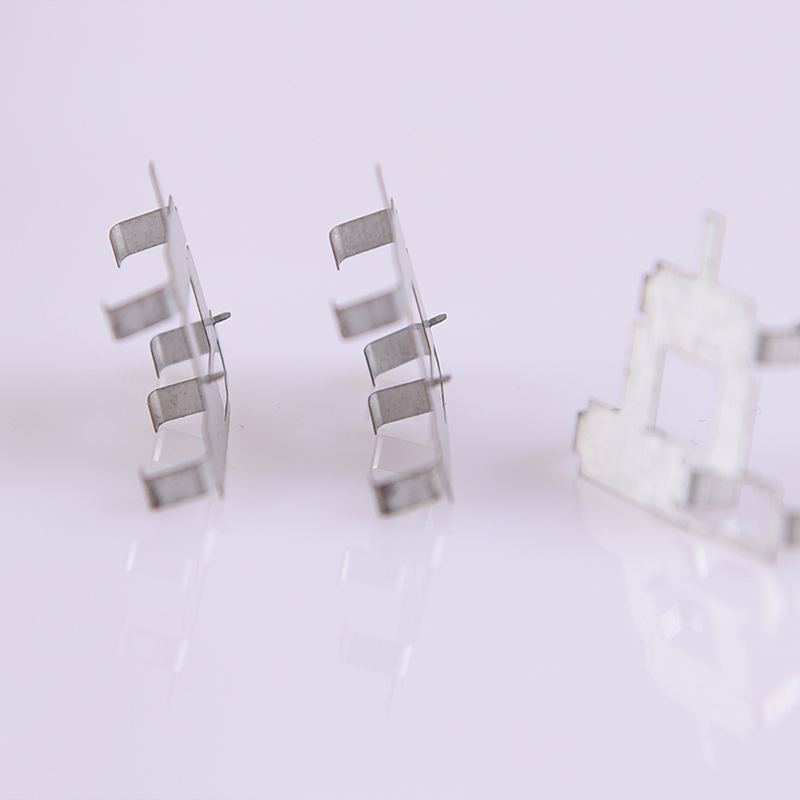

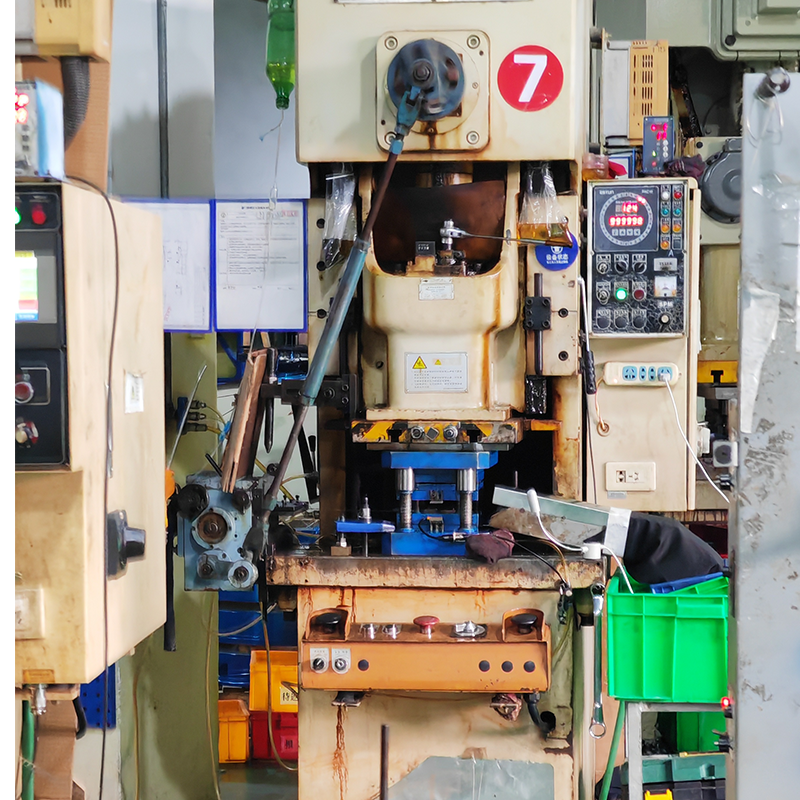

Stamping Process

The metal sheets or strips are processed through high-speed stamping presses, forming the desired contact shapes with exceptional precision and repeatability.

-

Deburring and Polishing

Stamped contacts undergo deburring and polishing to remove sharp edges and ensure a smooth, safe surface finish.

-

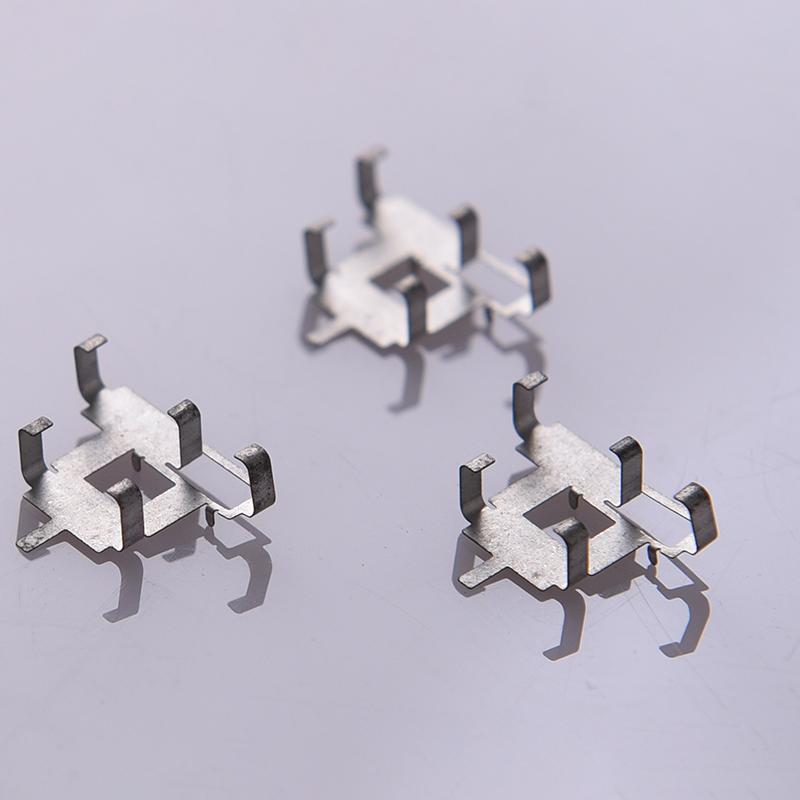

Surface Treatment

Contacts are plated with materials such as gold, silver, or tin to enhance electrical conductivity, corrosion resistance, and durability.

-

Inspection and Quality Control

Each contact is meticulously inspected using precision measuring equipment to ensure compliance with design tolerances and quality standards.

-

Packaging and Shipment

Finished contacts are carefully packaged to prevent damage during transit and shipped to the customer as per the agreed timeline and requirements.

Our Advantages:

– Cutting-Edge Manufacturing Technology

Leveraging advanced four-slide and multi-slide stamping techniques, we deliver high-precision wire lug metal connectors and components efficiently, making large-scale production both cost-effective and precise.

– Comprehensive In-House Tooling & Die Services

Our fully integrated tooling and die capabilities enable rapid design modifications and expedited production timelines, ensuring premium quality without incurring additional costs.

– Certified for Excellence

Operating under ISO 9001, ISO 14001, and IATF 16949 certifications, our facilities uphold stringent quality standards, ensuring the reliability and durability of every wire lug metal connector we produce.

– Cost-Effective Production with On-Time Delivery

Through optimized production processes and an advanced MRP system, we provide economical solutions while ensuring timely deliveries that seamlessly align with our customers’ schedules.