Overview:

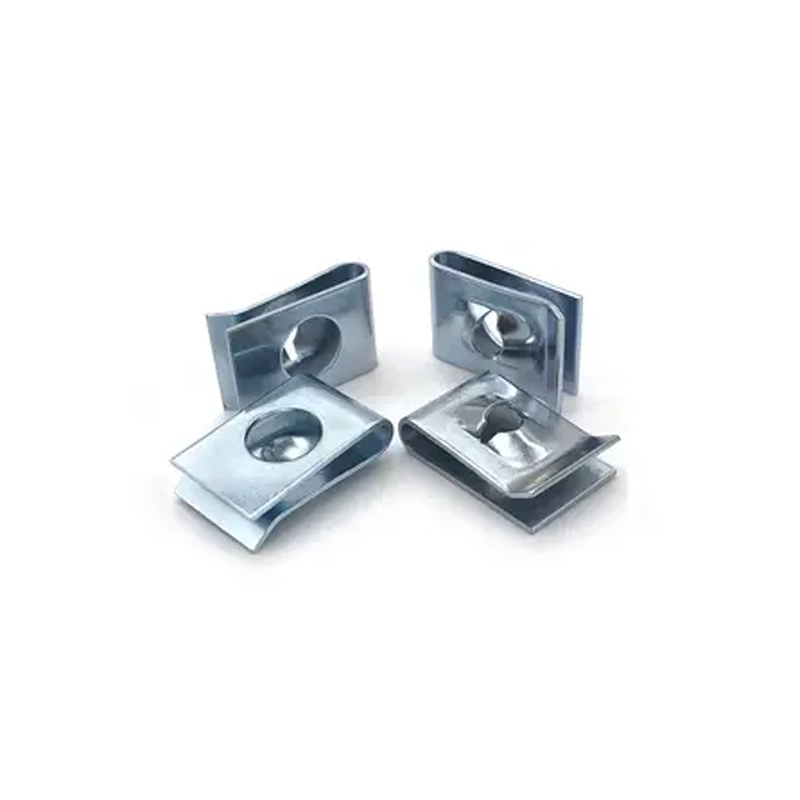

Metal stamped clips for automotive applications are precision-engineered components commonly used for securing parts within vehicle assemblies. These clips are primarily manufactured using metal stamping techniques, which involve high-pressure machines to shape and cut metal sheets into precise forms. The materials used for these clips typically include spring steel, stainless steel, or other high-strength alloys that offer durability and flexibility under demanding automotive conditions.

Our custom-made metal clips are crafted using top-quality materials, and are available with various surface finishes and treatments to ensure optimal performance, including zinc plating, powder coating, and nickel plating. These treatments enhance corrosion resistance, improve durability, and ensure long-lasting functionality in automotive environments.

Details:

| Attribute | Details |

| Brand | OEM |

| Certifications | ISO9001, IATF 16949 |

| Color | Custom |

| Size | Custom |

| Material | Carbon Steel / Spring Steel / 65Mn / Stainless Steel |

| Finish | Black, Zinc Coating, etc |

| Quality | Raw Materials and Finished Products Inspection |

| MOQ | Small Orders Accepted |

| Origin | Xiamen, China |

| Delivery Time | 7~15 days |

Production Process:

-

Material Selection

High-quality materials such as carbon steel, spring steel, stainless steel, or 65Mn are selected based on the specific requirements of the automotive application.

-

Design and Prototyping

The design phase involves creating detailed CAD drawings and prototypes to ensure precision and functionality in the final clip design.

-

Stamping

The stamping process uses high-pressure machinery to cut, bend, and shape the metal into the desired clip form. This is done using custom molds to achieve the required dimensions and tolerance.

-

Heat Treatment

Depending on the material, heat treatment may be applied to improve the strength, hardness, and durability of the clips.

-

Surface Finishing

After stamping, the clips undergo surface treatments such as zinc coating, black oxide, or other finishes to improve corrosion resistance, wear resistance, and aesthetic appeal.

-

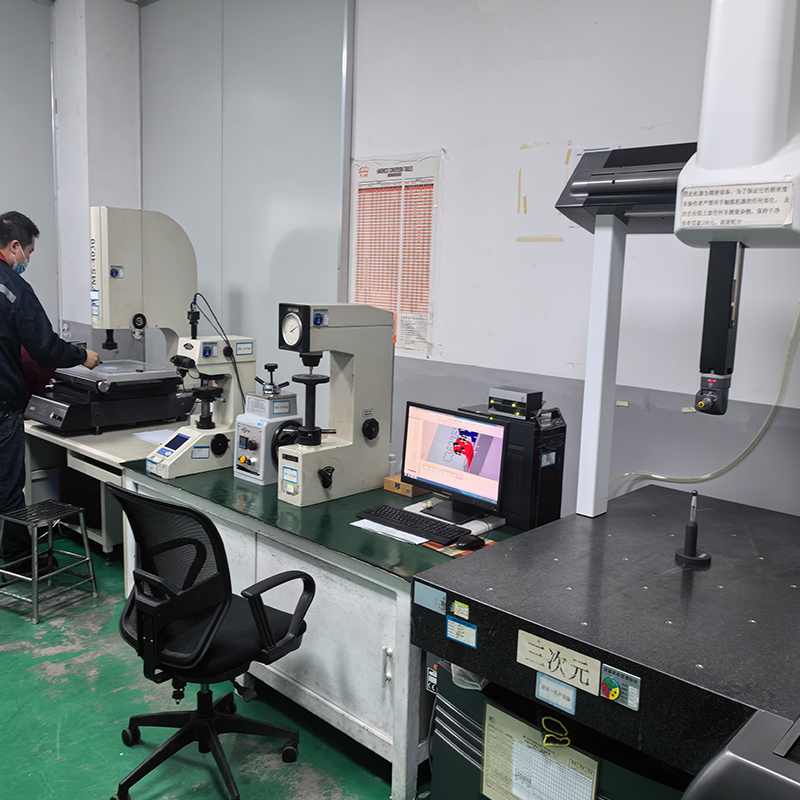

Inspection and Quality Control

Each batch of clips is rigorously inspected to ensure that they meet quality standards. This includes dimensional checks, tensile testing, and visual inspections.

-

Packaging and Shipping

Once inspected, the clips are carefully packaged for safe transport and delivery to customers, ensuring that they arrive in perfect condition.

Quality Control Process:

The quality control process for metal stamped clips used in automotive parts involves several critical steps to ensure precision, durability, and reliability. First, incoming raw materials such as carbon steel, spring steel, and stainless steel are inspected for compliance with quality standards. During production, dimensional checks are continuously conducted using advanced measurement tools like Coordinate Measuring Machines (CMM), calipers, and micrometers to ensure parts meet precise specifications. After stamping, each clip undergoes functional testing, including tensile strength tests and visual inspections for defects. Additional checks for corrosion resistance are performed using salt spray testing and other specialized equipment. The clips are also subjected to hardness testing using Vickers hardness testers to ensure they possess the required strength and durability. Every part is meticulously inspected to guarantee it meets both internal quality standards and industry requirements before being packaged and shipped.

Our Services:

Industry Expertise

With over 20 years of experience in the metal clips manufacturing industry, we combine in-depth technical knowledge with practical expertise to deliver tailored solutions that meet the unique requirements of our clients.

Sample Availability

We provide rapid access to product samples within 7 days, allowing you to evaluate quality and fit before proceeding with production. If the necessary tooling is available, we offer these samples at no additional charge.

Quick Turnaround

Our typical lead time is within 10 days, ensuring that we deliver high-quality metal clips and components swiftly and efficiently to meet your production deadlines and project needs.

Commitment to Excellence

We are committed to offering competitive pricing, exceptional customer service, and consistent product quality. Our goal is to provide valuable solutions that drive our clients’ success, with a focus on reliable and high-performance metal clips.