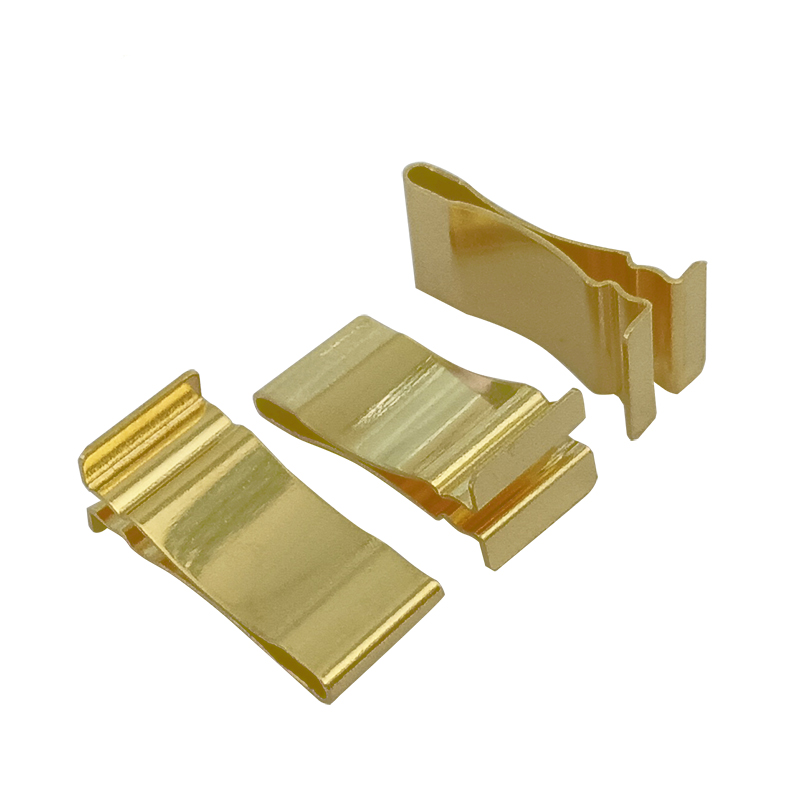

Description:

OEM gold-plated metal clips for electronic communication equipment are high-precision components that undergo an advanced electroplating process, where a thin layer of gold is applied to enhance conductivity, corrosion resistance, and overall durability. Manufactured through precision stamping or molding techniques, these clips are designed to perform reliably in high-demand environments. We offer customized gold-plating services for metal clips, providing a variety of sizes and surface treatments to meet the unique needs of each client. With a focus on quality assurance and timely delivery, our dedicated team ensures that every product meets stringent industry standards, offering tailored solutions for the electronic communication sector.

Product Details:

- Place of Origin: Xiamen, China

- Brand: OEM

- Size: Customizable

- Application: Electronic Communication Equipment

- Certification: ISO9001 / IATF16949

- Surface Treatment Options: Nickel Plating / Chrome Gold Plating

- Manufacturing Process: Progressive Stamping

- Thickness Range: 0.1-12.0mm (customizable as needed)

- Shape: OEM Sheet Metal Stamping & Bending

- Materials Available: Brass, Copper, Carbon Steel, Stainless Steel, and more

- Inspection Process: 100% Inspection Before Delivery

Why Partner with Us?

-

Tailored OEM & Assembly Solutions

With over two decades of experience, we specialize in providing custom OEM solutions and comprehensive assembly services. Our precision manufacturing processes are designed to meet your unique specifications and requirements.

-

Comprehensive Product Offering

We deliver a full range of products, including stamped components, CNC-machined parts, springs, shafts, fasteners, and more. As your trusted one-stop manufacturing partner, we provide seamless solutions for all your production needs.

-

Certified, Trusted Supplier

As a reliable second-tier supplier, we have successfully passed rigorous factory audits and hold essential industry certifications, such as RoHS and HE compliance, ensuring our products meet global standards.

-

Unwavering Commitment to Quality

Certified under ISO 9001:2015 and IATF 16949, we adhere to the highest standards of quality management, ensuring consistent and reliable production across all services we offer.

Production Process:

-

Material Selection

We begin with the careful selection of high-quality materials, such as brass, copper, carbon steel, or stainless steel, chosen for their excellent conductivity, strength, and corrosion resistance to meet specific application needs.

-

Stamping/Forming

The selected material is precisely shaped through a progressive stamping or molding process. This ensures high dimensional accuracy, smooth edges, and the integrity of the metal clips.

-

Surface Preparation

The clips undergo a comprehensive surface cleaning process to remove impurities, oils, and oxidation, ensuring optimal conditions for the subsequent gold plating and enhancing the adhesion of the plating layer.

-

Gold Electroplating

In this step, the clips are subjected to an electroplating process where a thin, uniform layer of gold is deposited onto the surface. The electroplating process improves the clips’ electrical conductivity, corrosion resistance, and overall durability.

-

Post-Plating Inspection

After plating, the clips are thoroughly examined to verify uniform gold coverage and quality. This inspection ensures that the plating is consistent, adheres properly, and meets all required specifications.

-

Final Quality Control & Inspection

A final 100% inspection is carried out to detect any defects in size, shape, or plating quality. Only those clips that pass all rigorous checks are approved for shipment, ensuring the highest quality standards.

-

Packaging & Delivery

The gold-plated metal clips are carefully packaged to prevent any damage during transport. We ensure prompt and secure delivery, with flexible options tailored to meet customer requirements.

Surface Treatment Options:

– Passivation

A chemical treatment that enhances the corrosion resistance of metals by forming a protective oxide layer. Ideal for stainless steel components, passivation improves durability and prevents rust.

– Silver Plating

A thin silver layer is applied to the metal surface to improve electrical conductivity, enhance corrosion resistance, and provide a smooth, aesthetically pleasing finish. Ideal for electronic components.

– Nickel Plating

Nickel plating offers superior hardness, corrosion resistance, and wear protection. This process is commonly used to improve the durability and lifespan of components exposed to harsh environments.

– Tin Plating

Tin plating provides a protective barrier against corrosion and improves solderability. It is commonly used in electrical applications where components need enhanced resistance to moisture and oxidation.