Overview:

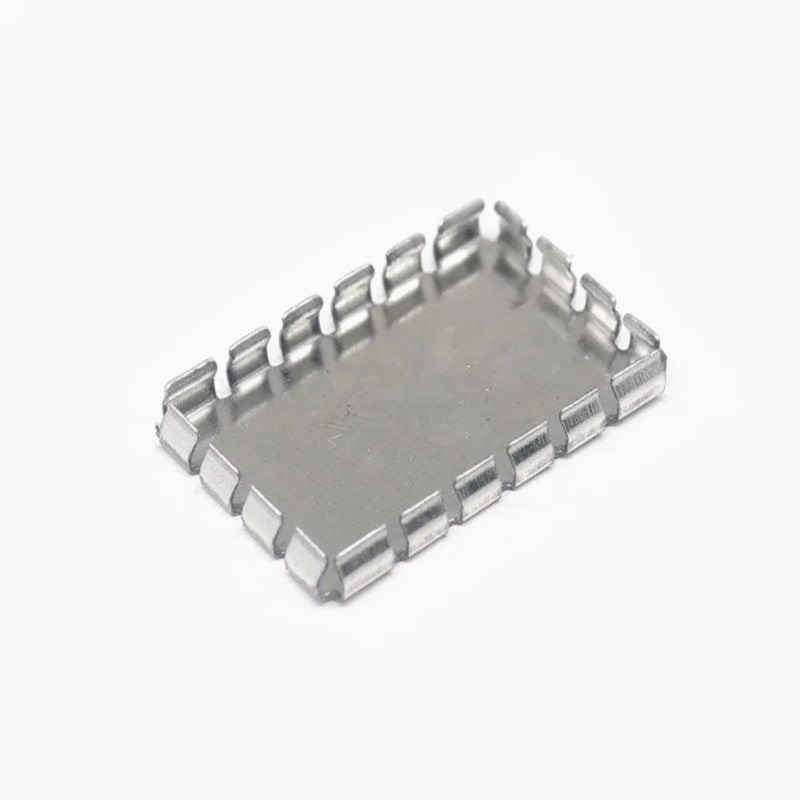

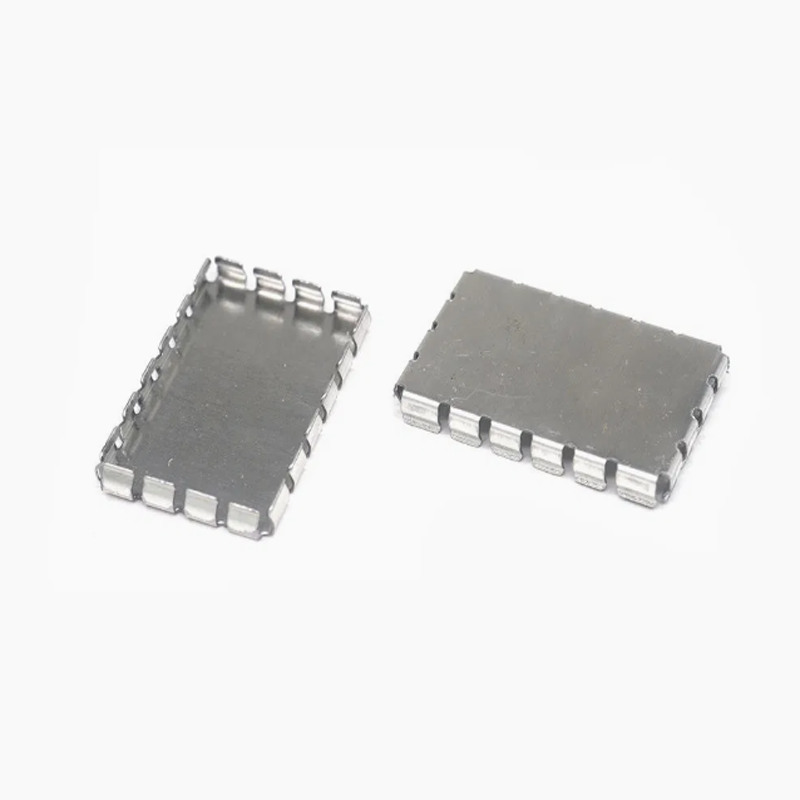

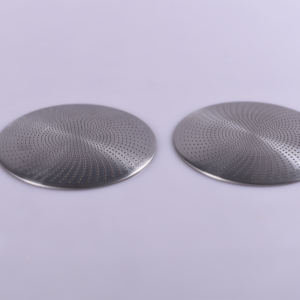

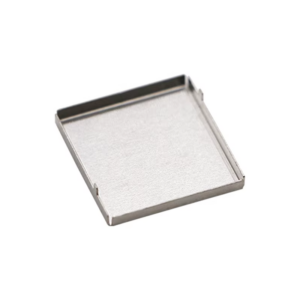

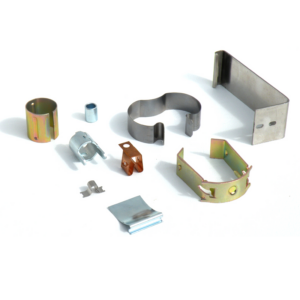

As a leading manufacturer and supplier of OEM metal shield components (enclosures/housings), we provide superior protection against electromagnetic interference (EMI) to ensure reliable performance in sensitive electronic systems. Made from conductive or magnetic materials, our stamped metal parts are designed for demanding applications, including automotive, where minimizing interference is critical for performance and safety. Trust us for durable, high-quality EMI shielding solutions tailored to your needs.

Details:

| Category | Details |

| Mould | In-House Die Making |

| Surface Processing | Electroplating |

| Process | Fine Blanking, Multi-Position, Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.02mm |

| Customization | Warmly Welcomed |

| Material Available | Copper, Stainless Steel, Carbon Steel, Aluminum, etc. |

| Usage | Automotive, Agriculture, Furniture, Machinery |

| Stamping Die | In-House Die Making |

| Samples | Free Available |

| Service | OEM |

| File Format | CAD, Solidworks, PDF, etc. |

| Transport Package | As Per Your Requests |

| Trademark | OEM |

| Origin | Xiamen, China |

Production Process:

- Material Selection: Choosing the appropriate material (e.g., copper, stainless steel, or aluminum) based on the required properties for electromagnetic shielding and durability.

- Die Design and Manufacturing: In-house design and production of custom dies for precision stamping, ensuring that each shield meets the specific shape and size requirements.

- Stamping: The die is used to stamp the metal material into the desired shape, producing high-precision components that fit perfectly into automotive assemblies.

- Surface Processing: Additional treatments like electroplating or coating are applied to enhance corrosion resistance and improve the shielding effectiveness.

- Quality Control: Each part undergoes thorough inspection to ensure it meets strict tolerances (typically 0.02mm) and functional requirements.

- Assembly and Packaging: The finished metal shields are carefully assembled and packaged for transport, ready for integration into automotive systems.

- OEM Service: Throughout the process, OEM customization options are offered, including tailored designs and branding according to customer specifications.

Surface Finishing Options:

- Electroplating: A process where a metal coating (such as zinc, nickel, or gold) is applied to the surface of the shield to improve corrosion resistance, durability, and conductivity.

- Powder Coating: A dry finishing process that provides a durable, smooth, and resistant surface. It helps protect the metal shield from harsh environmental conditions and wear.

- Anodizing: Commonly used for aluminum shields, anodizing enhances corrosion resistance and provides a hard, wear-resistant surface while also offering the option for color customization.

- Laser Etching/Engraving: This process uses a laser to mark or engrave logos, serial numbers, or other identifying marks on the metal shield, providing a precise and clean finish.

Our Factory:

At Plantmetal, we operate a fully equipped, state-of-the-art production facility designed to deliver the highest standards of quality in metal stamping. Our plant is outfitted with an extensive range of advanced machinery, including 25 punch presses with capacities ranging from 25 tons to 300 tons, precision wire EDM machines, grinding equipment, as well as welding, polishing, and ultrasonic cleaning systems. These resources enable us to efficiently produce high-precision components while maintaining the utmost consistency and accuracy.

In addition to our robust manufacturing capabilities, we provide a range of premium metal plating services to enhance the performance, appearance, and longevity of our stamped products. Our offerings include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. With our cutting-edge plating facilities, we guarantee uniform coatings, superior corrosion resistance, and full compliance with industry standards.

By combining automated production lines, advanced mechanical equipment, and stringent quality control protocols, we ensure that every metal stamping product we deliver meets the highest quality benchmarks. Our comprehensive approach enables us to consistently produce durable, reliable, and aesthetically superior products that meet the precise specifications of our clients.