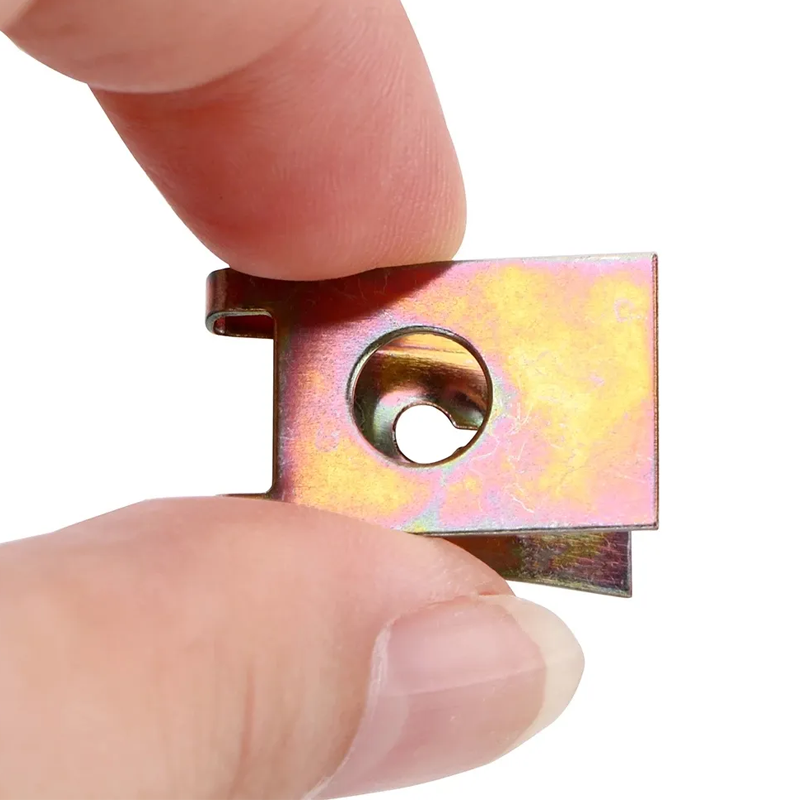

Overview:

Metal stamped fasteners for automotive applications are precision-made components typically crafted from materials like stainless steel, carbon steel, and aluminum. These fasteners offer exceptional durability, corrosion resistance, and dimensional accuracy, making them ideal for securely joining vehicle parts in demanding automotive environments.

Our custom services ensure tailored solutions for various fastener sizes and designs, with surface treatments to meet specific performance needs. We deliver high-quality, precision fasteners that comply with automotive industry standards. Contact us to discuss how our expertise can support your project with top-tier fasteners for your automotive applications.

Details:

| Attribute | Details |

| Material | Stainless Steel, SUS301/631 |

| Mould | Multistep Progressive Dies |

| Industry | Automotive Applications |

| Tolerances | 0.02mm |

| Customized | Yes |

| Brand Name | OEM |

| Press Capabilities | 16ton – 500ton |

| Capacity | Stamping, Punching, Welding, Machining, Extrusion |

| Samples | Available |

| File Format | CAD, Solidworks, Pdf, etc |

| Service | OEM |

| Transport Package | As per your requests |

| Specification | Customized |

| Trademark | OEM |

| Origin | China |

| Production Capacity | 500,000 pieces per month |

Advantages of Fasteners:

- High Precision

- Enhanced Durability

- Corrosion Resistance

- Cost-Effective Manufacturing

- Customizable Designs

- Strong Mechanical Properties

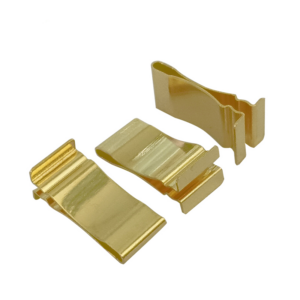

Surface Treatment Options:

- Passivation: A chemical treatment that enhances corrosion resistance by forming a protective oxide layer on stainless steel and alloys.

- Golden Plating: A decorative and protective coating of gold, improving corrosion resistance and electrical conductivity for high-end automotive applications.

- Silver Plating: A thin layer of silver for superior electrical conductivity, corrosion resistance, and wear protection in automotive parts.

- Nickel Plating: A durable coating that provides excellent wear resistance, heat, and corrosion protection, ideal for automotive applications.

- Tin Plating: A protective coating that resists corrosion and rust, commonly used for parts exposed to moisture in automotive environments.

Manufacturing Process:

- Material Selection: The process begins with selecting the appropriate material, such as stainless steel (SUS301/631), ensuring it meets the required strength, durability, and corrosion resistance for automotive applications.

- Tooling Design & Die Development: Precision tooling is designed using CAD or other advanced software, followed by the creation of progressive dies that allow for high-volume, precise stamping of components.

- Stamping and Punching: Using multi-step progressive dies, the material is fed into a stamping press, where the fasteners are precisely stamped or punched into their desired shape and size.

- Secondary Operations: Depending on the design requirements, additional processes such as welding, machining, or extrusion may be performed to refine the fastener’s shape or add specific features.

- Surface Treatment: The fasteners undergo surface treatments such as plating, coating, or anodizing to enhance their corrosion resistance, appearance, and durability.

- Inspection and Quality Control: Rigorous quality control measures are applied throughout the process, including dimensional inspections, mechanical testing, and visual checks, to ensure the fasteners meet the required specifications and standards.

- Packaging and Shipping: After passing inspection, the finished fasteners are packaged according to customer specifications and prepared for delivery, ensuring they reach the client in optimal condition and on time.

Our Factory:

We operate a state-of-the-art manufacturing facility equipped with a wide range of advanced machinery to guarantee top-tier production quality. Our plant features 25 punch presses with capacities ranging from 25 tons to 300 tons, along with precision wire EDM machines, grinding equipment, welding tools, polishing stations, and ultrasonic cleaning systems, ensuring versatility and precision in every project.

Beyond our extensive manufacturing capabilities, we offer a full spectrum of metal plating solutions designed to enhance both the functionality and aesthetic quality of our stamped products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating facilities are engineered to deliver consistent, high-quality finishes, exceptional corrosion resistance, and full compliance with industry standards.

This integration of advanced automation, top-quality mechanical equipment, stringent quality control protocols, and premium plating services ensures we consistently produce metal stamping parts that meet the highest standards of durability and performance.