Overview:

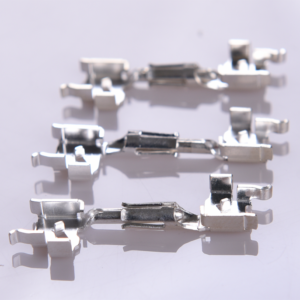

Electrical terminals are essential components for ensuring secure and dependable connections in various electrical systems. At our facility, we specialize in the design and production of custom metal-stamped electrical terminals tailored to meet the needs of demanding and mission-critical applications. Leveraging advanced manufacturing techniques such as four-slide and multi-slide forming, high-speed progressive die stamping, and precision CNC machining, our expert engineers ensure that every terminal meets the highest standards of quality, reliability, and accuracy. With a focus on precision and durability, we deliver electrical terminals that perform consistently under the most stringent conditions.

Details:

– Forming Process: Metal Stamping Parts

– Surface Finish Options: Nickel Plating, Sn Plating, Tin Plating, Zinc Plating

– Sample Availability: Available

– Tolerance: ±0.001 mm

– Size: Customizable as per requirement

– Application: Industrial, Furniture, Automotive, Motorcycle, etc.

– Manufacturing Approach: Metal Stamping, Cutting, Punching, Bending, Welding

– Transport Packaging: OPP Bag, Box, or Custom

– Specification: Customized

– Origin: Xiamen, China

Quality Test Process:

The quality process for electrical wire connectors includes several key steps to ensure reliability. It starts with material inspection to verify the quality of raw materials. Precision stamping is then performed using advanced die stamping machines, followed by electroplating for improved conductivity and corrosion resistance. Dimensional inspections ensure compliance with strict tolerances, while functionality tests like electrical conductivity, mechanical stress, and environmental simulations assess durability. Finally, connectors undergo assembly and packaging in clean conditions to maintain product integrity. This comprehensive process guarantees high-quality, reliable electrical wire connectors.

Why Choose Us?

Cost Efficiency

Our offshore metal stamping die manufacturing optimizes production costs, delivering significant savings without compromising on quality.

Exceptional Quality

Through meticulous quality control and stringent testing protocols, we ensure that every stamped part meets the highest industry standards.

Fast Turnaround

We prioritize efficiency, offering expedited production and shipping, with lead times as short as 15 days to meet your project deadlines.

Instant Pricing

Harnessing advanced technology, we provide immediate, accurate cost estimates for your metal stamping needs, enabling quicker decision-making.

Factory Show:

We operate a comprehensive range of plants and equipment to ensure the highest quality production. Our facilities are equipped with 25 punch presses ranging from 25 tons to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems.

In addition to our manufacturing capabilities, we offer a variety of metal plating processes to enhance the durability, appearance, and functionality of our metal stamping products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating facilities ensure consistent finishes, corrosion resistance, and compliance with industry standards.

This combination of professional and automated production lines, advanced mechanical equipment, rigorous quality control measures, and high-quality plating processes ensures we deliver metal stamping products of the highest standard.