Overview:

At our facility, we specialize in the precision manufacturing of custom metal stampings and assemblies. Among our diverse product range, we offer tailor-made metal brackets, designed and produced to meet the most demanding application specifications. Our custom metal bracket solutions encompass a wide array of design options, material choices, surface finishes, and other customizations to ensure optimal performance across a variety of industrial applications. Whether it’s for structural support, mounting, or specialized functions, our custom metal brackets are engineered to exceed expectations.

Details:

| Attribute | Details |

| Mould Type | Multistep Progressive Dies |

| Surface Processing | Electroplating, Fine Blanking |

| Process Type | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | ±0.02mm |

| Customization | Available |

| Length | 100-1000mm |

| Material | Stainless Steel |

| Delivery Time | 7-30 Days |

| R&D Capacity | OEM |

| Specification | Customization |

| Place of Origin | China |

Finishing Options:

- Polishing: Achieves a smooth, glossy surface finish for enhanced appearance and durability.

- Plain Finish: A basic, uncoated surface ideal for minimalistic designs and functional applications.

- Sandblasting: Provides a textured, matte finish with improved surface roughness for both aesthetic and functional purposes.

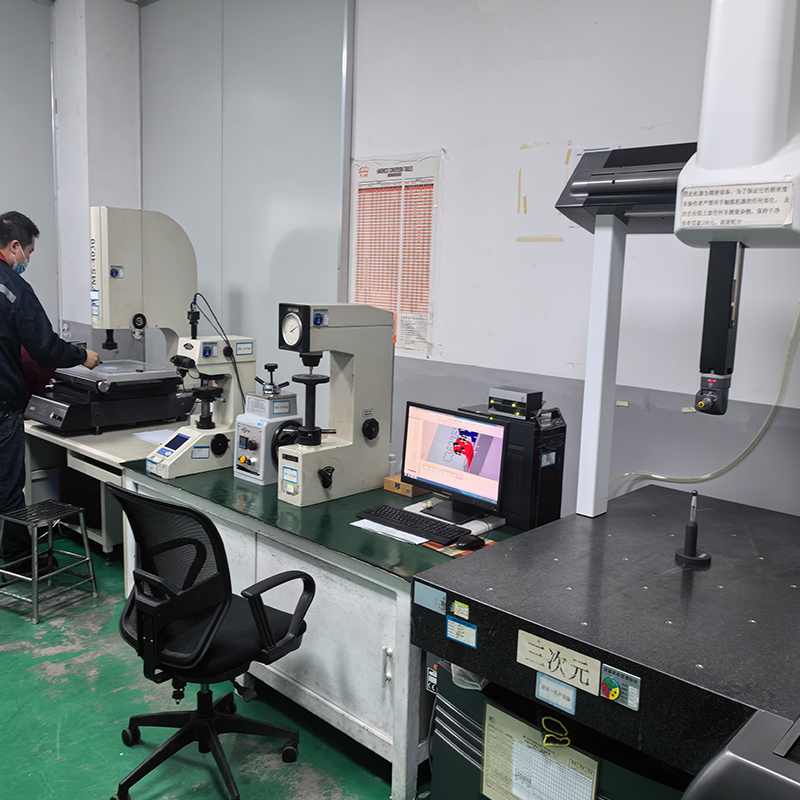

Quality Test Process:

The quality testing process for metal stamping sheet brackets includes a series of rigorous evaluations to ensure compliance with industry standards. Key tests include dimensional verification using high-precision measuring instruments such as calipers and CMM (Coordinate Measuring Machines) to confirm accuracy within tight tolerances. Surface integrity is checked through visual inspection and tests like salt spray for corrosion resistance and surface roughness measurement. Additionally, mechanical properties such as strength and flexibility are assessed through tensile testing and load-bearing capacity evaluations. Finally, any required functional tests, including fit and assembly checks, are performed to ensure the brackets meet the specified application requirements.

Our Services:

– We specialize in manufacturing fasteners tailored to meet buyers’ exact specifications and performance requirements.

– Our fasteners undergo rigorous durability testing and technical design assessments to ensure extended product lifespan.

– We offer competitive pricing, providing cost-effective solutions backed by our professional manufacturing capabilities.

– With over 20 years of experience, we offer a wide range of fastening solutions to effectively address any application needs.

Factory Overview: