Description:

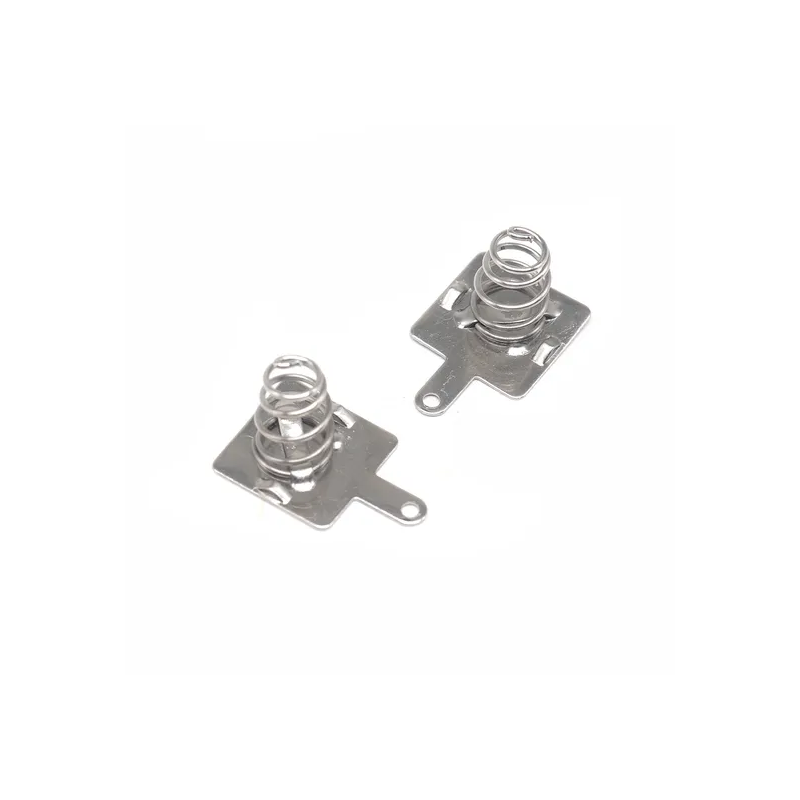

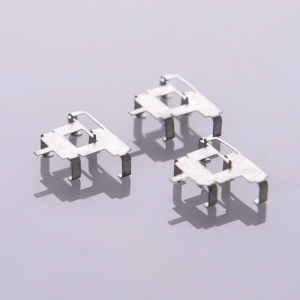

Nickel Plated Electronic Stamped Contacts for Electric Vehicle Charging Devices are made from high-quality copper and coated with nickel to enhance corrosion resistance and electrical conductivity. This plating ensures durability and reliability in high-performance EV charging applications.

Our factory offers custom manufacturing services, including tailored sizes, dimensions, and surface treatments such as zinc, chrome, and tin plating. With advanced stamping technology and strict quality control, we deliver high-quality, durable components for electric vehicle charging systems. Contact us for custom solutions to meet your specific needs.

Details:

| Attribute | Details |

| Usage | Industrial, Automotive, Furniture, Motorcycle, Home Appliance |

| Process | Metal Stamping |

| Size | Custom |

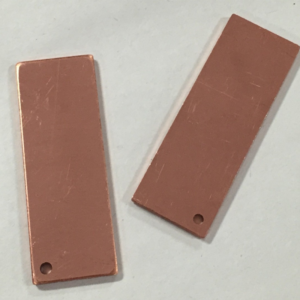

| Material | Copper, Brass |

| Shape | Custom |

| Service | Customized OEM |

| Drawing Format | 3D, CAD, DWG, Step, PDF |

| Transport Package | Inner Polybag, Outer Box, or Custom |

| Specification | Customized |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 20,000 units per week |

Production Process:

-

Material Selection & Preparation

Copper or brass is chosen for its conductivity and cleaned to remove contaminants for better plating adhesion.

-

Metal Stamping

High-precision stamping presses form the contacts into their custom shapes and sizes using specialized dies for accuracy.

-

Nickel Plating

Electroplating applies a nickel coating to enhance corrosion resistance, durability, and conductivity, with thickness carefully controlled.

-

Quality Control & Inspection

Each contact is inspected for dimensional accuracy, plating adhesion, and durability through tests like salt spray.

-

Post-Processing & Packaging

Secondary operations such as bending or cutting may be performed, followed by custom packaging to ensure safe delivery.

Other Surface Treatments:

-

Gold Plating

A thin layer of gold is electroplated onto the surface, providing excellent corrosion resistance, enhanced conductivity, and a polished appearance.

-

Silver Plating

Silver plating is applied to improve conductivity and reduce resistance, offering a highly durable and electrically efficient finish.

-

Tin Plating

A tin coating is used for corrosion resistance, particularly in harsh environments, while maintaining solderability and enhancing the overall durability of the component.

Factory Show:

We operate a state-of-the-art manufacturing facility equipped with a full range of advanced production equipment, ensuring top-tier product quality. Our capabilities include 25 high-performance punch presses (ranging from 25 tons to 300 tons), precision wire EDM machines, grinding and polishing stations, welding tools, and ultrasonic cleaning systems.

To further elevate the functionality, durability, and appearance of our metal stamping products, we provide a comprehensive suite of plating services. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our cutting-edge plating technology guarantees consistent, high-quality finishes, superior corrosion resistance, and adherence to the highest industry standards.

By combining sophisticated automation, advanced mechanical systems, stringent quality control processes, and premium plating options, we consistently deliver metal stamping products that meet and exceed the highest industry standards.