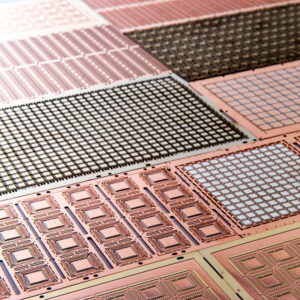

Overview:

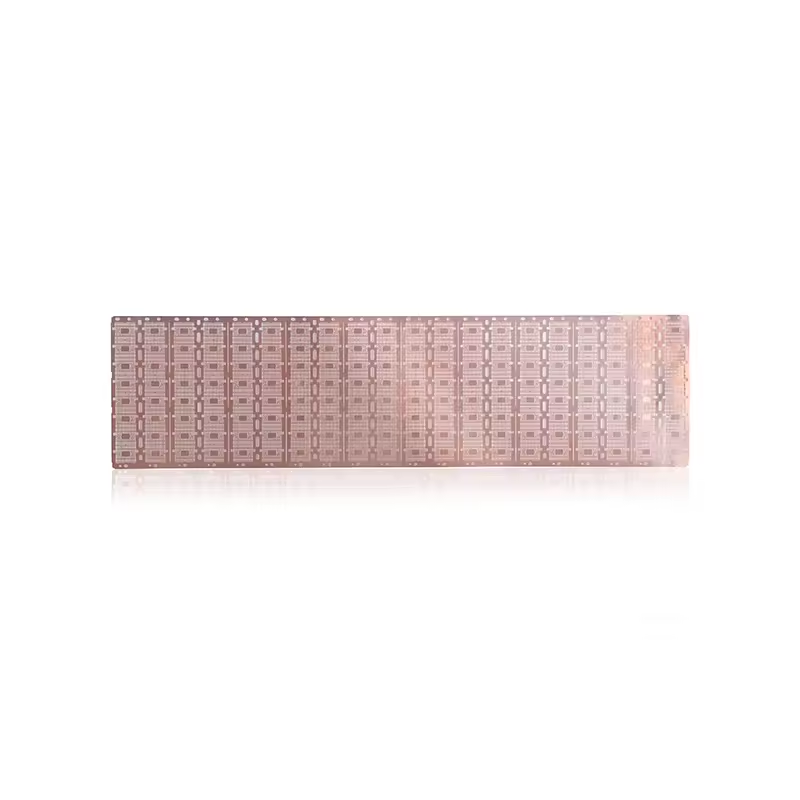

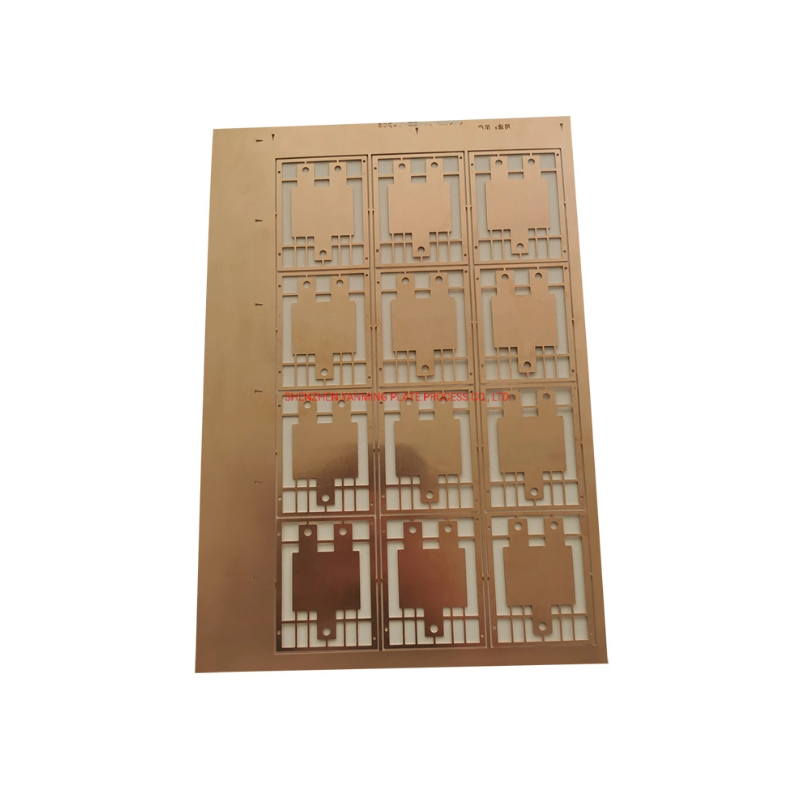

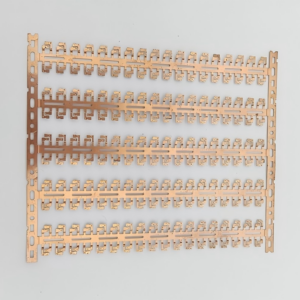

A semiconductor lead frame is a crucial component in semiconductor device assembly, providing structural support and electrical connections between the chip and external circuits. Typically made from high-conductivity metal alloys like copper, lead frames are manufactured through precision stamping and electroplating. This process ensures excellent electrical conductivity, mechanical strength, and corrosion resistance. The precision and efficiency of manufacturing also contribute to cost-effectiveness while maintaining high-quality standards.

Production Process:

- Design and Tooling: Initial design is created, followed by the development of precise tooling and molds. Computer-Aided Design (CAD) and advanced simulation techniques are used to ensure accuracy.

- Material Preparation: High-quality copper or alloy materials are selected and prepared. This includes cutting or rolling the metal to the required thickness.

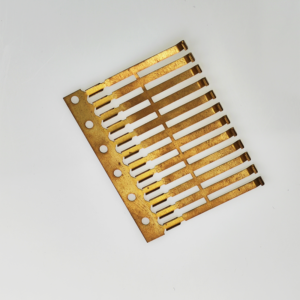

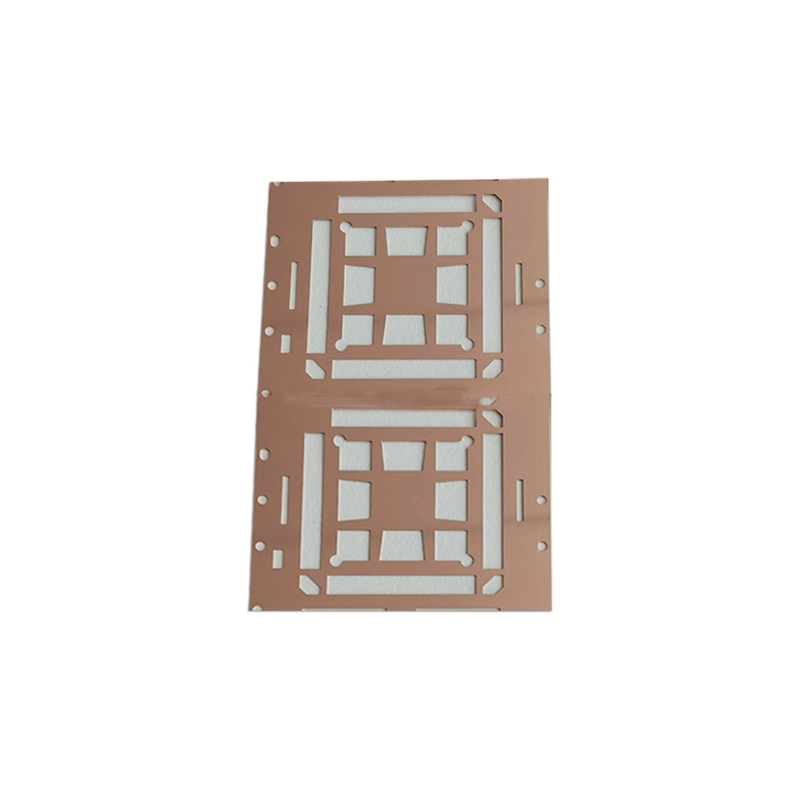

- Stamping and Punching: The prepared metal sheets are stamped or punched using high-precision dies to create the lead frame’s shape and outline. This step involves forming the frame with the correct lead positions and dimensions.

- Etching and Plating: The lead frames undergo chemical etching to remove unwanted metal and define fine features. This is followed by plating processes, such as gold or nickel plating, to improve conductivity and protect against corrosion.

- Assembly: The etched and plated lead frames are assembled into their final configurations, including attaching any necessary components.

- Inspection and Testing: Each lead frame is subjected to rigorous quality control checks, including dimensional verification, functionality testing, and visual inspection to ensure compliance with industry standards.

- Final Processing: The lead frames are cleaned, and any final surface treatments are applied. Customizations such as logos or specific color finishes are completed during this stage.

- Packaging: The finished lead frames are packaged according to specifications to prevent damage during shipping and to prepare them for distribution.