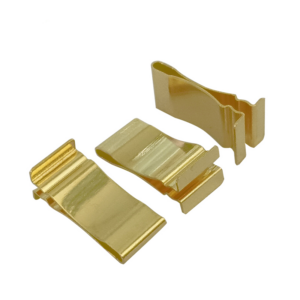

Overview:

Our precise silver plating stamped metal clips are made from premium brass or stainless steel and finished with silver plating for superior conductivity and corrosion resistance. Known for high precision and high quality, these clips are ideal for electrical applications requiring reliability and durability. We offer customizable sizes and material options, providing a one-stop service for all your manufacturing needs.

Features:

| Item | Details |

| Service | OEM |

| Size | Custom |

| Processing Type | Progressive Stamping |

| Material | Iron, Carbon Steel, Stainless Steel, Copper, Brass |

| Surface Processing | Zinc/Nickel/Tin/Chrome/PVD Plated, Anodize, Polish, Fine Blanking |

| Industry | Metal Stamping Parts |

| Tolerances | 0.01mm |

| Customized | Yes |

| Dimensions | As Drawings or Samples |

| Trademark | OEM |

| Transport Package | Custom |

| Origin | China |

Production Process:

- Material Selection: High-quality materials like iron, stainless steel, or copper are chosen for their strength and suitability for stamping.

- Cold Stamping: The raw material is shaped into the clip design using precise cold stamping, ensuring tight tolerances.

- Progressive Stamping: Clips are refined through multiple die stages for precise shaping and clean edges.

- Silver Plating: A silver coating is applied to enhance conductivity, corrosion resistance, and aesthetics.

- Surface Finishing: Additional treatments like polishing or anodizing provide a smooth, durable finish.

- Quality Control: Clips are inspected for dimensional accuracy and plating quality, with a typical tolerance of 0.01mm.

- Packaging and Delivery: Clips are securely packaged for safe transport to customers.

Quality Control Process:

At our factory, quality is paramount. We begin each project with a feasibility review to ensure manufacturability and perform a run-at-rate study to verify quality before full production begins. Our quality management system integrates advanced technology, continuous improvement, and a dedicated lab team to oversee the process.

We employ in-line and off-line camera vision systems and sensor technologies, tailored to each project, working alongside our stamping equipment to ensure precise inspections of every silver-plated stamped metal clip. This guarantees 100% quality assurance and zero defects.

Trust Plantmetal for high-quality, precision-engineered silver-plated stamped metal clips. Our expert team and cutting-edge equipment ensure reliable, on-time delivery without compromise.

Factory Show:

Our state-of-the-art facilities feature a comprehensive range of equipment designed to ensure top-quality production. With 25 punch presses, ranging from 25 to 300 tons, along with precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems, we maintain the highest manufacturing standards. To further enhance the durability and appearance of our metal stamping products, we offer a variety of metal plating options, including electroplating, zinc, nickel, chrome plating, and anodizing. Our advanced plating facilities deliver consistent finishes, superior corrosion resistance, and compliance with industry standards. This combination of cutting-edge technology, automated production lines, and strict quality controls ensures the exceptional quality of every product we produce.