Description:

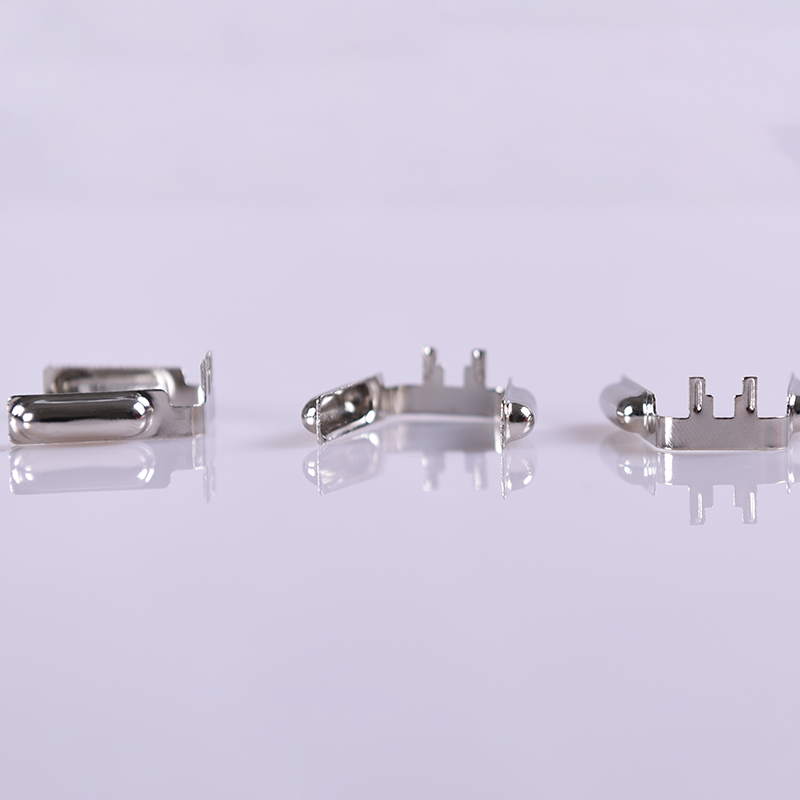

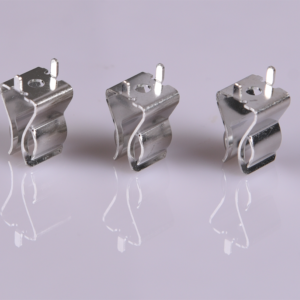

Metal stamping spring clips play a crucial role in car chargers, ensuring reliable electrical connections and maintaining consistent contact for optimal power transfer. These clips are manufactured with precision stamping techniques and are typically crafted from durable, conductive materials such as stainless steel or beryllium copper. These materials offer superior elasticity, excellent corrosion resistance, and long-lasting performance.

We specialize in providing custom OEM spring clips, designed to meet your specific requirements, including size, material selection, and surface treatments. Our high-quality, cost-effective solutions are engineered to enhance the performance and reliability of your car charger applications. Reach out to us today to discuss your custom spring clip needs!

Features:

| Attribute | Details |

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Size | Custom |

| Thickness | Custom |

| Materials | Zinc, Aluminum, Copper, Steel, Stainless Steel, Brass, Beryllium Copper, etc. |

| Surface Treatment | Electric Plating, Powder Coating, Sand Blasting, Lacquer |

| Process | Punching, Stamping, Bending, Riveting, etc. |

| Technology | Metal Stamping |

| OEM | Accept |

| Certification | ISO 9001:2008, IATF 16949 |

Why Partner with Us?

-

Tailored Solutions & OEM Capabilities

We provide customized solutions and OEM services, offering expert guidance and flexible options to meet your exact specifications. From sample provision to bespoke design recommendations, we ensure the ideal fit for your application needs.

-

Rigorous Quality Control & Testing

Our products undergo comprehensive testing, including a mandatory 72-hour salt spray test, to guarantee durability and performance. Additionally, we offer secondary processes like drilling, plating, and heat treatment to meet the most demanding standards.

-

Seamless Assembly & Customized Packaging

We manage the entire assembly process, from welding and installation to custom packaging, ensuring your products arrive in perfect condition and ready for use.

-

Competitive Pricing & Reliable Delivery

Enjoy cost-effective pricing without compromising quality. We offer flexible order quantities and ensure timely delivery, with lead times ranging from 10 to 20 days depending on the order size, so you can count on us to meet your deadlines.

Production Process:

-

Material Selection

We begin by selecting premium materials like stainless steel, aluminum, or beryllium copper, chosen for their superior strength, conductivity, and corrosion resistance. These materials are sourced in sheet or coil form, ready for further processing.

-

Cutting & Shaping

The raw materials are precisely cut and shaped using advanced pressing equipment. This step ensures that the base components are formed with high accuracy, aligning with the design specifications required for the stamping process.

-

Stamping & Forming

Utilizing high-speed stamping presses, the materials are transformed into spring clip components. Our stamping process achieves precise dimensions, while bending operations are performed to create the required curvature and structural integrity.

-

Joining & Welding

In cases where multiple components need to be connected, we employ welding or other joining techniques to ensure the finished spring clips possess the necessary strength and durability.

-

Coating & Surface Finishing

To improve the clips’ resistance to corrosion and enhance their appearance, we apply various surface treatments, including electroplating, powder coating, and other finishing methods, depending on the specific requirements of the application.

-

Assembly & Quality Assurance

If the design requires, we carry out final assembly operations. All products undergo rigorous quality control to verify they meet dimensional accuracy, structural soundness, and functionality standards.

-

Packaging & Shipping

The finished spring clips are carefully stored and packaged to prevent damage during transit, ensuring that they reach customers in perfect condition and ready for installation.

Our Manufacturing Facility:

We operate a comprehensive range of advanced manufacturing technologies and equipment to ensure the highest standards of production quality. Our facility is equipped with 25 high-performance punch presses, ranging from 25 to 300 tons, along with precision wire EDM machines, grinding tools, welding stations, polishing systems, and ultrasonic cleaning equipment.

To elevate the performance, longevity, and aesthetics of our metal stamping components, we provide an extensive selection of metal plating services. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing, all performed in our state-of-the-art plating lines. Our plating processes are designed to deliver consistent coatings that provide superior corrosion resistance and meet stringent industry specifications.

By integrating cutting-edge production lines, high-precision mechanical equipment, and a robust quality assurance framework with a full suite of plating options, we consistently deliver metal stamping products that exceed industry standards for quality and reliability.