Overview:

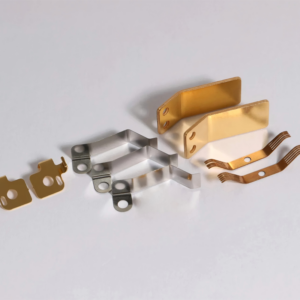

Stainless steel acid passivation terminal clips are designed for superior corrosion resistance and reliability, making them ideal for applications in the automotive, electronics, telecommunications, and energy industries. As a trusted supplier, we manufacture these clips using precise stamping and acid passivation processes, ensuring high-quality, durable, and efficient solutions. We offer customized production services to meet your specific requirements, providing professional, tailored solutions for diverse applications.

Details:

| Attribute | Details |

| Material | Stainless Steel |

| Mould | In-House Die Making |

| Surface Processing | Acid Passivation |

| Process | Forming Process |

| Tolerances | 0.02mm |

| Customization | Warmly Welcomed |

| Material Available | Copper, Stainless Steel, Carbon Steel, Aluminum, etc. |

| Usage | Automotive, Agriculture, Furniture, Machinery |

| Press Capabilities | 25ton-300ton |

| Samples | Provided |

| Service | OEM |

| File Format | CAD, Solidworks, PDF, etc. |

| Transport Package | As Per Your Requests |

| Trademark | OEM |

| Origin | Xiamen, China |

Manufacturing Process:

- Material Selection: High-quality stainless steel is chosen for its excellent corrosion resistance, strength, and durability, ensuring the clips perform reliably in demanding environments.

- Die Design and In-House Die Making: Custom die sets are designed and manufactured in-house to meet precise specifications for the terminal clips, ensuring accurate and consistent production.

- Stamping Process: The stainless steel material is fed into stamping presses, where the die set shapes and forms the clips using high-pressure forming techniques, typically in press ranges from 25 tons to 300 tons.

- Acid Passivation: After stamping, the clips undergo an acid passivation process, which removes any contaminants from the surface and enhances the corrosion resistance, ensuring longevity and durability in harsh conditions.

- Quality Inspection and Tolerancing: The clips are carefully inspected to ensure they meet stringent dimensional tolerances, typically within ±0.02mm, and are tested for functionality and surface finish.

- Surface Finishing: Depending on customer requirements, additional surface treatments, such as polishing or coating, may be applied to further enhance the appearance and durability of the clips.

- Final Inspection and Packaging: The completed terminal clips undergo final inspection for quality control before being packaged according to customer specifications, ensuring safe transport and delivery.

Why Choose Us?

- High-Quality OEM Service

- Fast Shipping

- Strict Quality Control (ISO9001, IATF16949 Certified)

- Competitive Pricing

Factory Show:

We operate advanced facilities equipped with 25 punch presses (25-300 tons), precision wire EDM machines, grinding equipment, and ultrasonic cleaning systems to ensure top-quality production. Additionally, we offer a range of metal plating services—including electroplating, zinc plating, nickel plating, chrome plating, and anodizing—to enhance durability, appearance, and functionality. Our state-of-the-art equipment, coupled with rigorous quality control and high-quality plating processes, ensures the consistent delivery of superior metal stamping products that meet industry standards.