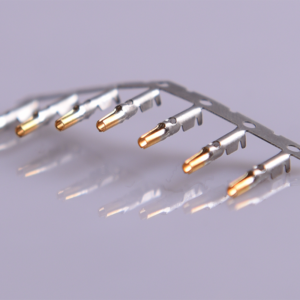

Overview:

Progressive stamping die pressing for electrical terminals is a precision manufacturing process used to create high-quality electrical terminals, typically made from materials such as copper, brass, or phosphor bronze. This advanced process involves a series of progressive stamping steps to shape and form the terminals, ensuring accuracy and consistency in high-volume production. The primary advantage of progressive stamping is its ability to produce complex, precision parts quickly and efficiently, with minimal waste and tight tolerances, making it ideal for applications in automotive, electrical, and consumer electronics industries. Our factory specializes in OEM services, offering customizable solutions for electrical terminals, optimizing device performance with durable and reliable parts. As an industry-leading supplier, we provide stamped metal parts and assemblies that meet the highest standards for demanding applications.

Features:

| Parameter | Details |

| Technics | Forming Die |

| Process Combination | Progressive Die |

| Manufacturing Technology | Automation Technology |

| Driving Motor Type | Reaction Type |

| Mold Cavity Technology | EDM Milling |

| Milling Speed | High Speed |

| Parts Detection Method | Measurement of Three Axis NC |

| Tooling Life | 1-3 Million |

| Speed | 300 SPM |

| Finish | Gold, Nickel, Tin, Copper Plated |

| Delivery Time | 15-35 Days |

| Transport Package | Custom |

| Trademark | OEM |

| Origin | Xiamen, China |

Finishing Operations:

– Deburring: The process of removing sharp edges, burrs, or imperfections from the surface of a part to ensure smoothness and safety.

– Tapping: The process of creating internal threads in a part to facilitate the insertion of screws or bolts.

– Reaming: The operation of enlarging a hole to precise dimensions and achieving a smooth, uniform finish.

– Counterboring: The technique of creating a larger, flat-bottomed hole to accommodate a fastener’s head, ensuring a flush fit with the part’s surface.

Order Process for Electrical Terminals

-

Submit Technical Drawings and Specifications

Provide us with the detailed drawings, including specifications for quality, mold lifespan, materials, and any other specific requirements for your electrical terminals.

-

Receive a Comprehensive Quote

We will provide a detailed quote outlining the costs for mold creation, part production, material selection, and any additional services required.

-

Negotiate Terms

We will work with you to finalize key details such as quality standards, pricing, material choices, delivery timelines, payment terms, and any other specific project requirements.

-

Order Confirmation and Initial Payment

Once all terms are agreed upon, an order is placed with an initial down payment to begin the production process.

-

Design for Manufacturability (DFM) Review

We analyze your designs and provide a Design for Manufacturability (DFM) assessment to ensure that the mold and production processes are optimized for efficiency and precision.

-

Mold Design Approval

The mold design is submitted for your review and approval before we proceed with manufacturing the mold and tooling.

-

Material Procurement and Machining

Upon approval, we order the required steel materials and begin machining the molds, providing you with weekly updates on production progress.

-

Assembly and Initial Testing

The mold/stamping die is assembled and tested with initial trials to produce sample electrical terminals.

-

Sample Inspection and Confirmation

Samples are inspected, and an inspection report is sent to you for confirmation. If the samples meet your specifications, we finalize the mold/tooling. If modifications are needed, we revise the mold until it meets your requirements.

-

Final Delivery

Once the mold is finalized and production is complete, the goods are shipped via your preferred method, whether by sea or air, ensuring timely and safe delivery.

Our Advantages:

– Rapid Quote Response: Receive accurate quotes within hours, not days, to accelerate your decision-making process.

– Quick Production Turnaround: Enjoy fast delivery of high-quality, consistent parts in days, not weeks, to keep your project on schedule.

– Complimentary Manufacturability Review: Optimize your design with a free evaluation to ensure seamless production and cost efficiency.

– Comprehensive OEM Solutions: Tailored manufacturing services that meet your exact specifications.

– Unrestricted Customization: Get precisely what you envision—your design, with no compromises.