Description:

Progressive Stamping Stainless Steel Metal Clips are precision parts made from high-quality stainless steel (304, 316, 430). Manufactured using the progressive stamping process, they offer high production efficiency, reduced material waste, and consistent quality for large volumes.We provide one-stop services from custom design to manufacturing and packaging. With advanced equipment and precise quality control, we can meet a wide range of product specifications, ensuring superior quality and on-time delivery.

Features:

| Item | Details |

| Place of Origin | Xiamen, China |

| Material | Spring steel, carbon steel, stainless steel |

| Surface Treatment | Nickel plating |

| Packing | Inner plastic bags, carton box, or as per customer request |

| Quality Control | Full inspection before shipment |

| Application | Automotive, motor, electronics, telecommunication equipment |

| Delivery Time | 15-25 workdays |

| Service | OEM |

Quality Control Process:

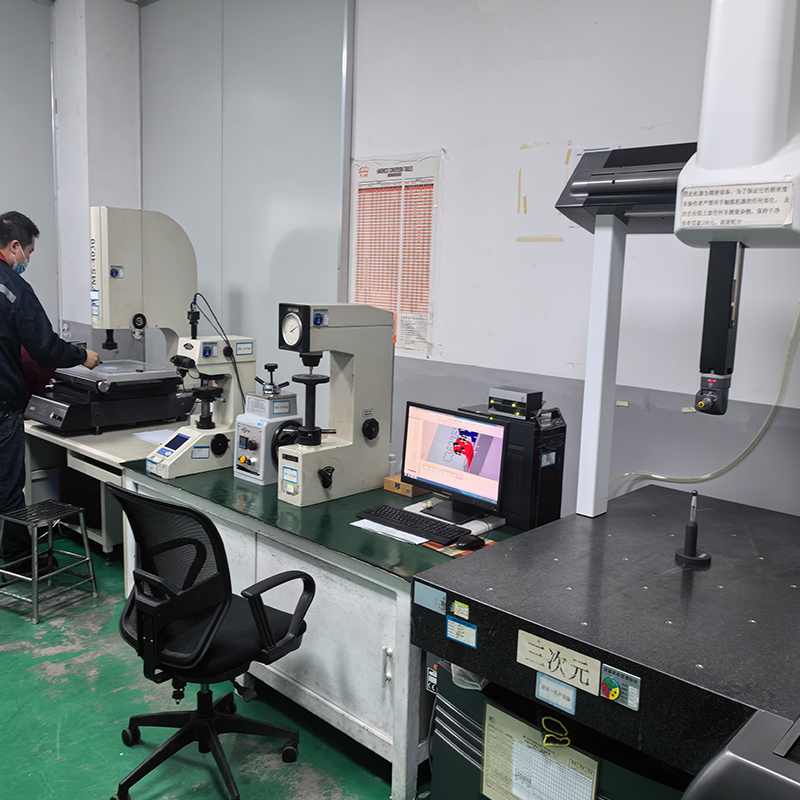

The Quality Control Process for Progressive Stamping Stainless Steel Metal Clips involves several critical steps to ensure consistent product quality. This includes incoming material inspection, dimensional verification using CNC measurement systems, and visual inspections for surface defects. The clips undergo tensile testing, hardness testing, and fatigue testing to meet mechanical performance standards. Advanced machines such as 3D projectors, coordinate measuring machines (CMM), and high-precision stamping presses are utilized to ensure accuracy. Additionally, electronic inspection systems are employed for real-time quality monitoring during production. The entire process is overseen by a dedicated quality control team to guarantee that all products meet the highest industry standards before shipment.

Our Advantages:

Expert Team

Timely Delivery

Quality Assurance

20 Years of Manufacturing Experience

Competitive Pricing

Premium Customer Service

Our Factory:

We operate a comprehensive range of plants and equipment to ensure the highest quality production. Our facilities are equipped with 25 punch presses ranging from 25 tons to 300 tons, precision wire EDM machines, grinding equipment, welding and polishing tools, and ultrasonic cleaning systems.

In addition to our manufacturing capabilities, we offer a variety of metal plating processes to enhance the durability, appearance, and functionality of our metal stamping products. These include electroplating, zinc plating, nickel plating, chrome plating, and anodizing. Our state-of-the-art plating facilities ensure consistent finishes, corrosion resistance, and compliance with industry standards.

This combination of professional and automated production lines, advanced mechanical equipment, rigorous quality control measures, and high-quality plating processes ensures we deliver metal stamping products of the highest standard.