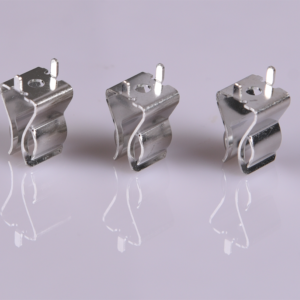

Visão Geral:

As presilhas metálicas de mola são elementos de fixação essenciais, conhecidos pela sua versatilidade e eficiência na fixação de componentes. Utilizadas numa variedade de aplicações, estas presilhas oferecem uma fixação resiliente, garantindo a estabilidade e o alinhamento correto das peças conectadas. A principal vantagem destas presilhas reside nas suas características elásticas, que lhes permitem flexionar e absorver choques ou vibrações, proporcionando assim uma ligação segura e fiável. Fabricadas através de processos precisos de estampagem metálica, estas presilhas são produzidas de acordo com especificações exatas, assegurando um desempenho consistente e durabilidade. A tecnologia de estampagem metálica permite a produção de presilhas metálicas de mola de alta qualidade, com designs complexos e tolerâncias apertadas, tornando-as adequadas para aplicações industriais e comerciais exigentes.

Acabamentos de Superfície:

- Zincagem: Aumenta a resistência à corrosão e o apelo visual.

- Niquelagem: Melhora a resistência à corrosão e aumenta a dureza superficial.

- Revestimento a pó: Oferece um acabamento durável e esteticamente agradável que protege contra a corrosão e o desgaste.

- Anodização: Usada principalmente em clipes de alumínio, este processo forma uma camada protetora de óxido para aumentar a resistência à corrosão.

- Passivação: Aplicada a clips de aço inoxidável, este tratamento remove o ferro livre, aumentando a resistência à corrosão.

Processo de Produção:

- Seleção de Material: Escolha o material apropriado, tipicamente aço para molas ou aço inoxidável, para garantir que o clipe tenha a resistência e elasticidade necessárias.

- Corte em bruto: Utilizar uma prensa de estampar para cortar peças planas (blanks) a partir do material selecionado, seguindo especificações precisas de tamanho e forma.

- Conformação: Utilizar matrizes especializadas para dobrar e moldar a peça bruta numa configuração em V, assegurando o ângulo e as dimensões corretos para a sua funcionalidade.

- Tratamento Térmico: Aplicar processos de tratamento térmico, como a têmpera, para melhorar as propriedades mecânicas da mola de fixação, aumentando a sua resistência e flexibilidade.

- Acabamento de Superfície: Realizar tratamentos de superfície, como galvanização, pintura a pó ou revestimento, para aumentar a resistência à corrosão e melhorar o aspeto estético do clipe.

- Controlo de Qualidade: Realizar rigorosos controlos de qualidade ao longo de todo o processo de produção, incluindo inspeções dimensionais e testes funcionais, para garantir que cada clipe cumpre as normas e especificações da indústria.

- Embalagem: Finalmente, embale os clipes de mola estampados em forma de V acabados de forma adequada para envio, garantindo que estejam protegidos durante o transporte e prontos para distribuição.

Exibição da Fábrica:

Operamos uma ampla gama de instalações e equipamentos para garantir a produção da mais alta qualidade. As nossas instalações estão equipadas com 25 prensas de estampagem com capacidades que variam entre 25 toneladas e 300 toneladas, máquinas de corte por fio EDM de precisão, equipamentos de retificação, ferramentas de soldadura e polimento, e sistemas de limpeza por ultrassom.

Para além das nossas capacidades de fabrico, oferecemos uma variedade de processos de revestimento metálico para melhorar a durabilidade, aparência e funcionalidade dos nossos produtos de estampagem metálica. Estes incluem galvanoplastia, zincagem, niquelação, cromagem e anodização. As nossas instalações de revestimento de última geração garantem acabamentos consistentes, resistência à corrosão e conformidade com os padrões da indústria.

Esta combinação de linhas de produção profissionais e automatizadas, equipamentos mecânicos avançados, medidas rigorosas de controlo de qualidade e processos de galvanização de alta qualidade garante que entregamos produtos de estampagem metálica do mais alto padrão.