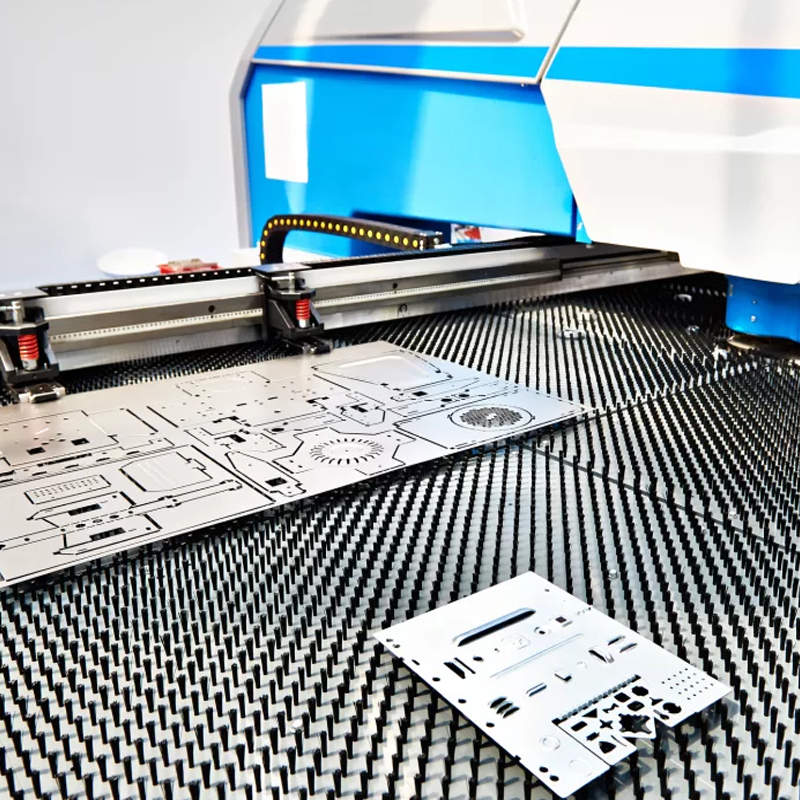

Punching has long been a preferred method for cutting and separating materials, particularly in the metalworking industry. Its advantages often surpass those of laser cutting, making it a vital technique in manufacturing. In this post, we will explore the intricacies of sheet metal punching, detailing its various types, benefits, drawbacks, and situations where outsourcing this process may be advantageous.

The Advantages of Sheet Metal Punching

If your project involves creating numerous deformations, perforations, or openings in sheet metal, punching is the method of choice. Here are some key advantages of this processing technique:

Precision

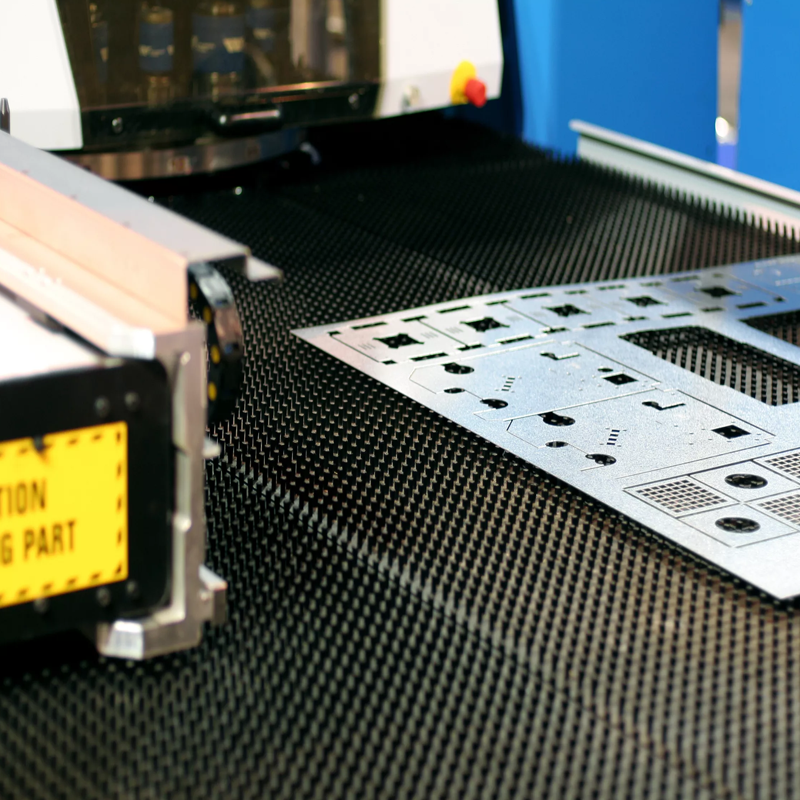

Modern punching tools are engineered for exceptional precision and dimensional accuracy. This allows for the rapid production of identical, accurately fitting sheet metal components, ensuring consistent quality across batches.

Versatility

Punching offers a diverse array of shaping options. It excels at forming and drilling operations, making it the go-to method for producing features such as recesses, beads, gills, and threads.

Simplicity

As a mechanical processing method, punching does not require excessive preparation time or thermal treatment. Unlike laser cutting, which involves melting, punching streamlines the manufacturing process, enhancing efficiency.

Cost and Energy Efficiency

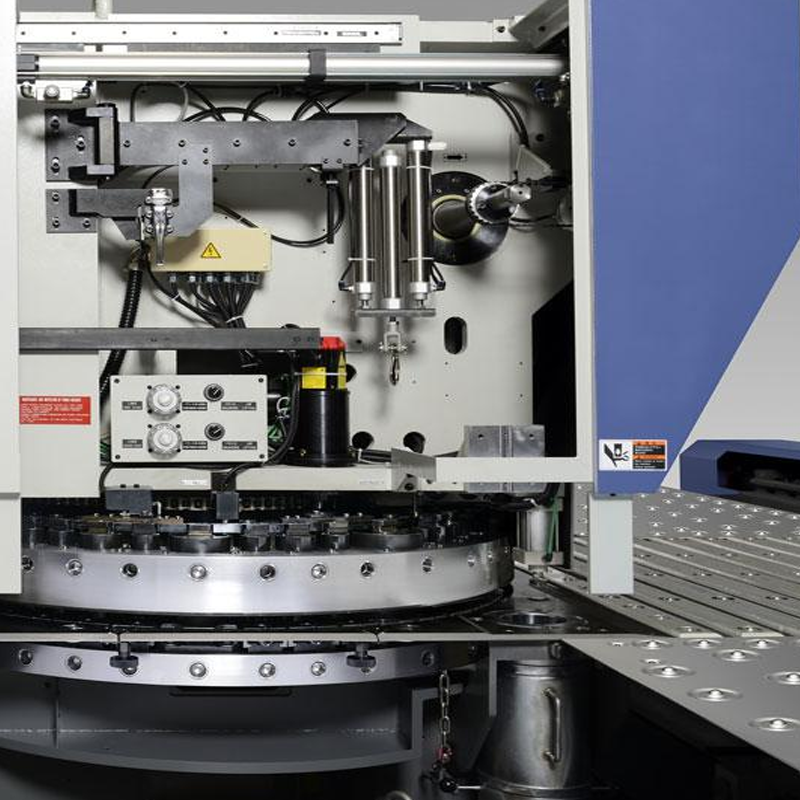

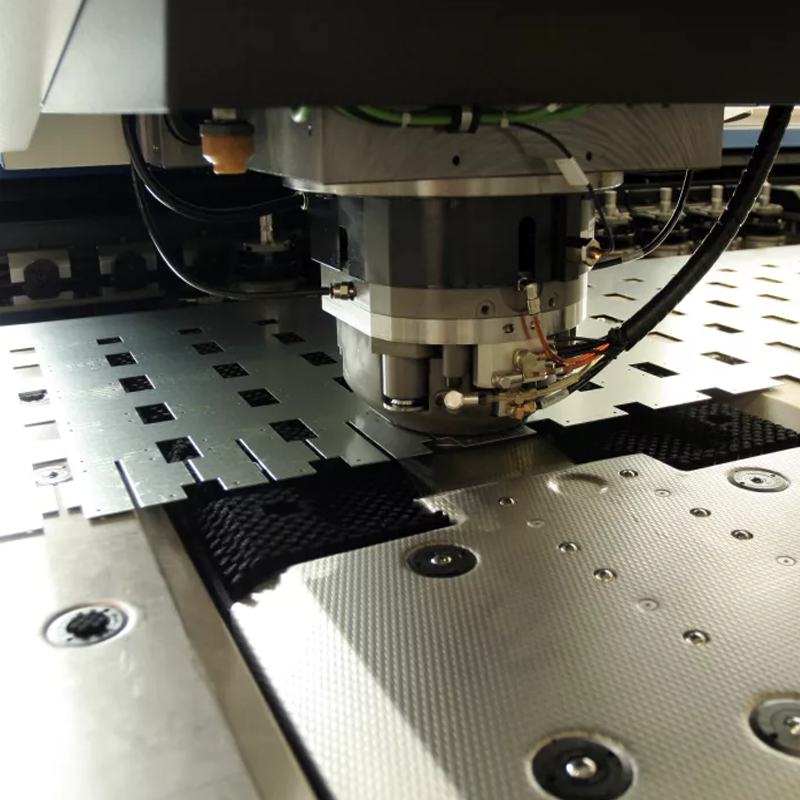

Contemporary machining centers utilize CNC technology for automated punching, significantly reducing production time and costs. The absence of thermal processing also contributes to energy savings, making it a sustainable choice for manufacturers.

Key Benefits at a Glance

– Cost-effective and energy-efficient production

– Precise cut-outs, openings, and embossing capabilities

– Ideal for high-volume series production

– Mechanical processing that avoids thermal deformation

– High throughput with consistently high-quality results

Common Techniques in Sheet Metal Punching

Punching encompasses various materials, primarily metal, which is typically supplied in sheet form. In addition to the metal industry, this technique is also employed in the paper, textile, and plastics sectors. Modern punching machines serve multiple functions beyond simple punching. Key techniques include:

– Cutting: Often achieved through wedge or shear cutting methods.

– Forming: Punching machines can bend materials using specialized tools, offering advantages over laser technology.

– Joining: This process combines two workpieces through methods like riveting, pressing, or folding.

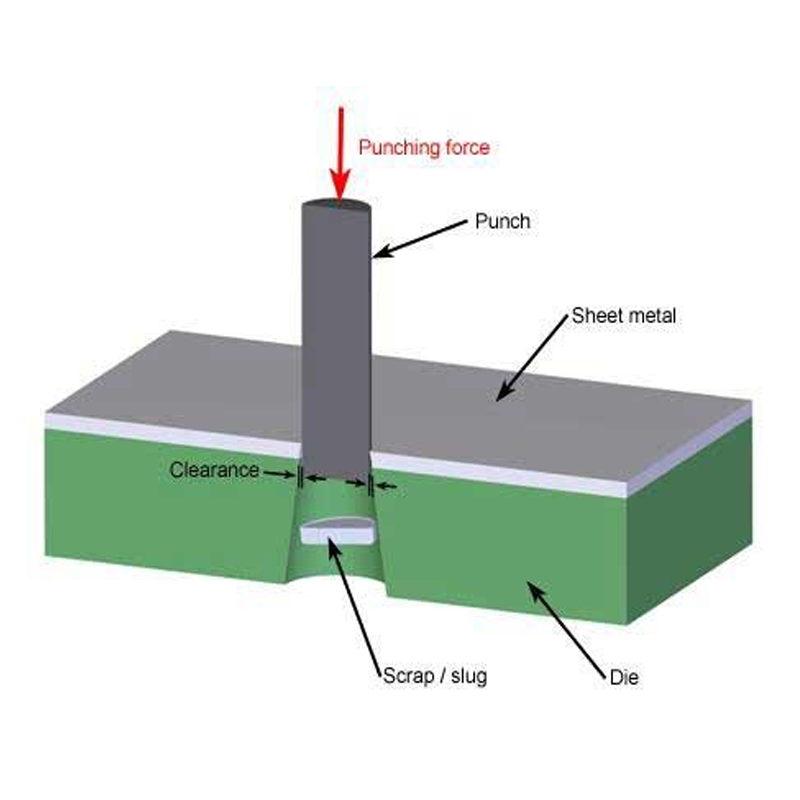

Shear Cutting Explained

Shear cutting is a critical aspect of the punching process, which can be categorized into various types, including:

– Cutting Out: Involves shapes with a closed cutting line.

– Cutting Off: The classic method of cutting along a specified line.

– Punching: Creates holes in sheet metal, making the closed cutting line evident.

– Notching: Involves cutting sections along the edge of the material.

– Incision: Prepares material for bending or drawing, resulting in partial separation.

– Trimming: This method removes excess material to refine edges.

– Nibbling: A gradual technique for material removal that allows for detailed shaping.

Considerations and Challenges

While punching offers numerous advantages, it does have some limitations:

High Initial Costs

Investing in professional punching equipment can be costly. For businesses focusing on smaller-scale projects, outsourcing to specialized providers like Plantmetal can be a more economical choice.

Limited Flexibility

Punching is best suited for larger production runs. The complexity of smaller designs increases the difficulty of achieving desired outcomes, especially as the size of the hole must correspond to the thickness of the sheet metal.

Need for Post-Processing

Older punching tools may produce a burr—a raised edge that requires removal for optimal results. Modern facilities often include deburring tools to enhance edge quality and efficiency.

Our choice of materials

- Alumínio

- Cobre

- Latão

- Bronze

- Stainless steel

- Aço

- Spring steel

Conclusion

Punching remains a time-honored technique in the manufacturing sector, standing strong alongside advanced laser technologies. It is a high-precision method that allows for rapid and cost-efficient production of sheet metal components.

At Plantmetal, we specialize in delivering high-quality punched sheet metal products with minimal defects. Our extensive inventory includes hundreds of punching tools and combination tools, enabling us to meet your specific requirements swiftly and affordably. Contact us today to learn more about how our sheet metal punching services can benefit your projects.