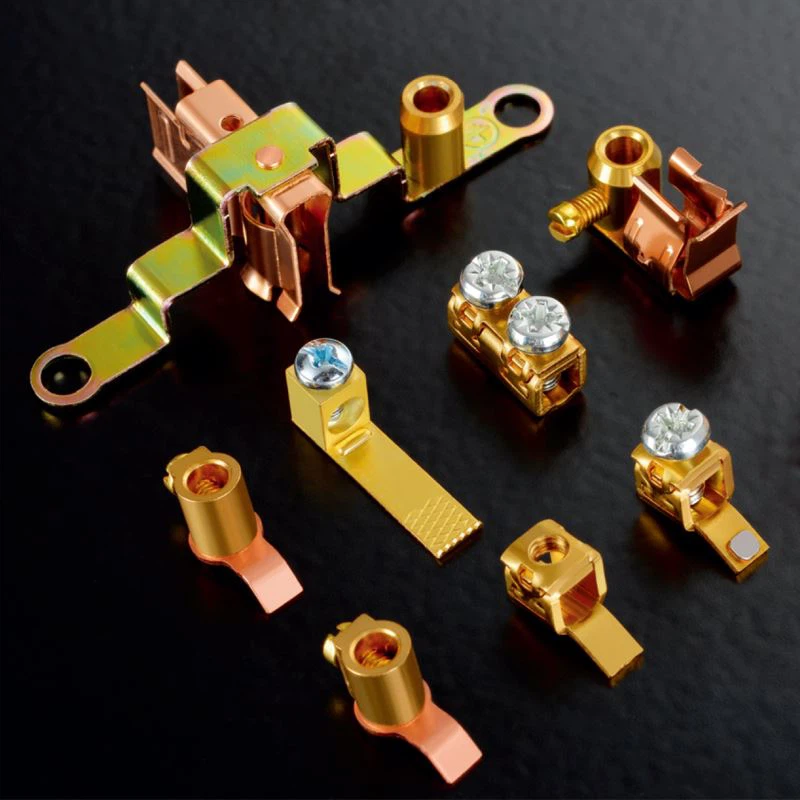

Visão Geral:

Os nossos produtos de contacto elétrico em prata são meticulosamente concebidos e produzidos para cumprir os mais elevados padrões de qualidade e fiabilidade. Ao tirar partido da tecnologia avançada de soldadura em matriz, garantimos uma consistência e estabilidade excecionais dos produtos ao longo de todo o processo de produção.

Estes contactos elétricos metálicos em prata não só oferecem um desempenho extraordinário, como também apresentam uma vantagem significativa em termos de custo. Ao utilizarmos a tecnologia de soldadura em matriz, conseguimos otimizar a produção, permitindo a fabricação em grandes volumes, o que reduz os custos e melhora a eficiência geral do processo produtivo.

Detalhes:

| Especificação | Detalhes |

| Craftsmanship | Carimbo, CNC |

| Terminar | Revestimento (Eletrodeposição, Revestimento de Níquel, etc.) |

| Preço | Preços em Tempo Real na Fábrica |

| Embalagem | Interior: Saco de plástico e espuma de PE; Exterior: Embalagem de cartão |

| Serviços | Serviços OEM disponíveis para designs e especificações personalizadas. |

| Local de Origem | Xiamen, China |

| Opções de Materiais | Alumínio, Aço Inoxidável, Latão, Cobre, Plástico, etc. |

| Opções de Cores | Branco, Preto, Vermelho, Azul, Prateado, Dourado, Cores personalizadas disponíveis |

| Certificações | ISO9001:2015, Certificado pela SGS |

| Capacidade de Produção | 5.000 unidades por dia (por máquina) |

| Tempo de Entrega | 7–15 dias, dependendo do tamanho e da complexidade da encomenda |

| Testando | Inspeção a 100%, Inspeção por terceiros mediante solicitação |

| Opções de Envio | DHL, FedEx, UPS, TNT, EMS, por via marítima, por camião ou por comboio |

Processo de Produção:

- Seleção de Materiais: Prata de alta pureza e outros materiais de liga são cuidadosamente selecionados para garantir excelente condutividade elétrica, durabilidade e resistência à corrosão.

- Design e Fabrico de Moldes: Os designs de moldes de precisão são criados utilizando software avançado de CAD/CAM para garantir a modelagem ideal dos componentes de contacto elétrico. Os moldes são posteriormente fabricados com alta precisão, recorrendo a máquinas CNC ou outras técnicas avançadas.

- Estampagem e Moldagem: Os materiais brutos são estampados utilizando máquinas de estampagem de alta precisão, formando o formato básico dos contactos elétricos. Este processo é cuidadosamente monitorizado para garantir dimensões e qualidade consistentes.

- Soldadura In-Die: Para determinados designs, a tecnologia de soldadura in-die é utilizada para unir componentes durante o processo de estampagem. Isto garante conexões fortes e sem juntas visíveis, eliminando a necessidade de etapas adicionais de montagem.

- Tratamento de Superfície: Os contactos elétricos passam por vários tratamentos de superfície, como galvanização, polimento ou revestimento, para melhorar a sua durabilidade, condutividade elétrica e resistência ao desgaste e à corrosão.

- Inspeção e Testes: Cada lote de contactos elétricos de metal de prata é submetido a testes rigorosos, incluindo verificações dimensionais, inspeções visuais e testes de desempenho elétrico, para garantir a conformidade com as especificações e os padrões da indústria.

- Embalagem: Após aprovação, os contactos elétricos são cuidadosamente embalados para evitar danos durante o transporte, garantindo que cheguem em condições ótimas.

- Envio: O produto final é então enviado aos clientes, com opções de envio expresso ou standard, dependendo dos requisitos do cliente.

Opções de Tratamento de Superfície:

– Anodização: Proporciona um acabamento durável e resistente à corrosão, com maior dureza superficial, ideal para componentes de alumínio.

– Revestimento em Pó: Proporciona um acabamento resistente e de alta qualidade, que é resistente a lascas, riscos e desbotamento, disponível numa ampla gama de cores.

Pintura: Oferece um acabamento liso e esteticamente agradável, com excelente aderência, ideal para aplicações tanto de proteção como decorativas.

Jateamento de areia: Produz uma textura uniforme e mate em superfícies metálicas, melhorando a sua aparência e preparando-as para tratamentos de acabamento adicionais.

Polimento: Alcança um acabamento de alto brilho, semelhante a um espelho, que melhora o apelo visual da superfície, ao mesmo tempo que proporciona uma textura suave e refinada.

Exibição da Fábrica: