Descrição:

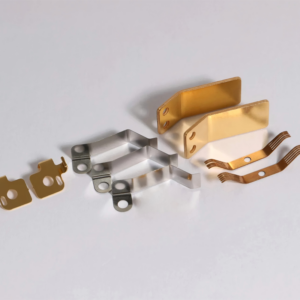

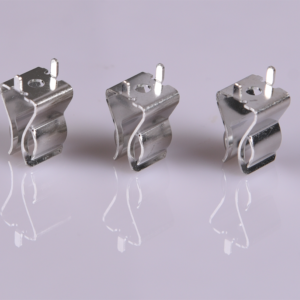

Clips metálicos em aço inoxidável com estampagem personalizada são componentes de precisão fabricados através do processo de estampagem de metal, utilizando materiais de alta qualidade como aço inoxidável, aço mola e aço carbono. Estes clips são concebidos para atender a requisitos específicos de desempenho em diversas aplicações, incluindo automóvel, aeroespacial e máquinas industriais. Oferecemos tamanhos personalizados e uma vasta gama de opções de tratamento de superfície, como zincagem, óxido negro ou passivação, para melhorar a durabilidade, resistência à corrosão e desempenho geral.

As presilhas de chapa metálica podem funcionar como grampos, fixadores ou suportes, aplicando pressão para manter os objetos firmemente unidos. As nossas presilhas metálicas personalizadas são amplamente utilizadas em aplicações como painéis de instrumentos, conjuntos de pára-choques, sistemas de travagem ABS e interruptores de controlo. Com a nossa experiência em design personalizado e fabrico de precisão, fornecemos soluções que cumprem as suas especificações exatas e garantem um desempenho fiável e de alta qualidade em ambientes exigentes.

Funcionalidades:

| Atributo | Detalhes |

| Tipo de Processamento | Moldar Metal |

| Material | Zinco, Alumínio, Cobre, Aço, Latão, etc. |

| Bolor | Corte Progressivo de Múltiplas Etapas |

| Corte de Precisão | Multiposições |

| Processo | Estampagem, Quinagem, Corte a Laser, Soldadura |

| Indústria | Peças de Estampagem Metálica |

| Tolerâncias | ±0,01 mm |

| Personalizado | Disponível |

| Espessura | 0,1 mm – 12 mm |

| Certificação | ISO 9001:2015, RoHS |

| Marca Registada | OEM |

| Pacote de Transporte | Saco de plástico/embalagem de bolhas de ar + caixas de cartão + caixa de madeira |

| Especificação | OEM |

| Origem | China |

Opções de Superfície:

-

Eletrogalvanização

Um processo onde uma fina camada de metal é depositada na superfície dos clipes através de uma reação eletroquímica, aumentando a resistência à corrosão e a durabilidade.

-

Revestimento por pulverização

Uma técnica que aplica uma fina névoa de material de revestimento à superfície dos clipes, proporcionando um acabamento uniforme e, ao mesmo tempo, aumentando a proteção contra o desgaste e os fatores ambientais.

-

Polimento

Um processo mecânico de acabamento que alisa a superfície dos clipes, melhorando a estética e proporcionando uma aparência refinada e de alto brilho.

-

Oxidação

Um método de tratamento que cria uma camada controlada de óxido na superfície do metal, melhorando a resistência à corrosão e aumentando a longevidade geral dos clipes.

As Nossas Vantagens

-

Especialização em Fabrico OEM

Especializamo-nos na produção de uma vasta gama de componentes OEM, incluindo peças estampadas em metal, maquinadas, de embutição profunda e conformadas em chapa metálica, com uma variedade de acabamentos de superfície adaptados às especificações do cliente.

-

Vantagem de Localização Estratégica

As nossas instalações em Dongguan, na província de Guangdong, oferecem uma proximidade estratégica aos principais portos de Shenzhen, permitindo-nos fornecer soluções de envio mais rápidas e económicas, ao mesmo tempo que melhoramos as nossas capacidades de serviço para clientes internacionais.

-

Maquinaria Avançada e Mão-de-Obra Qualificada

Equipados com maquinaria de ponta para puncionamento, soldadura, maquinação CNC, fresagem e retificação, garantimos precisão e fiabilidade em todas as etapas da produção. A nossa equipa de profissionais qualificados opera estes sistemas avançados com o máximo cuidado e atenção ao detalhe.

-

Especialização e Suporte Técnico Dedicados

A nossa equipa é composta por técnicos experientes focados no desenvolvimento técnico contínuo, garantindo que nos mantemos na vanguarda da inovação na produção. Apoiados por uma equipa dedicada de engenheiros profissionais e especialistas em comércio externo, estamos empenhados em fornecer um apoio e serviço excecionais aos nossos clientes.

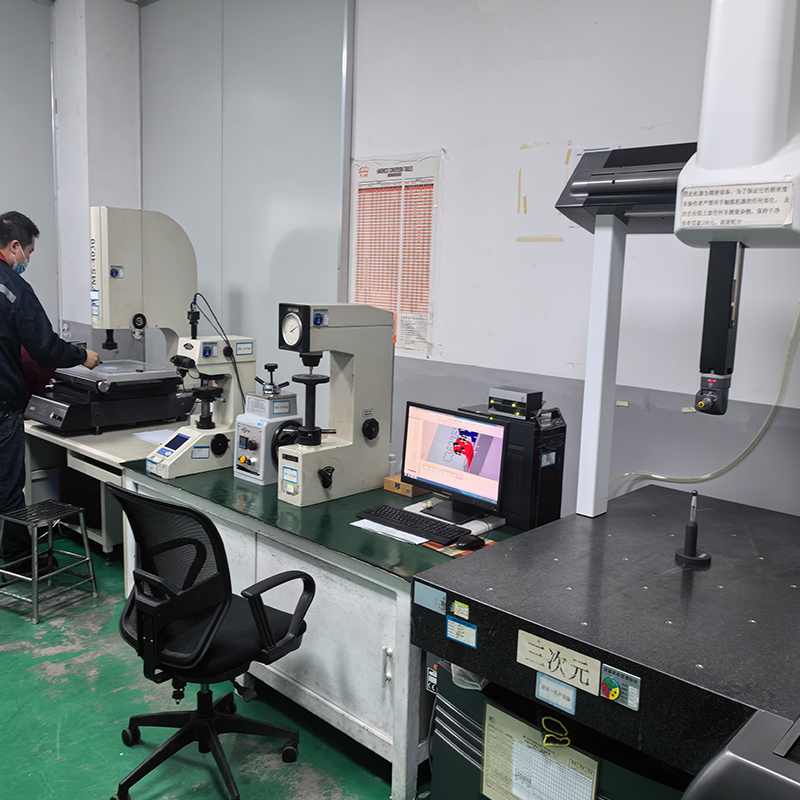

Exibição da Fábrica:

Operamos uma ampla gama de instalações e equipamentos para garantir a produção da mais alta qualidade. As nossas instalações estão equipadas com 25 prensas de estampagem com capacidades que variam entre 25 toneladas e 300 toneladas, máquinas de corte por fio EDM de precisão, equipamentos de retificação, ferramentas de soldadura e polimento, e sistemas de limpeza por ultrassom.

Para além das nossas capacidades de fabrico, oferecemos uma variedade de processos de revestimento metálico para melhorar a durabilidade, aparência e funcionalidade dos nossos produtos de estampagem metálica. Estes incluem galvanoplastia, zincagem, niquelação, cromagem e anodização. As nossas instalações de revestimento de última geração garantem acabamentos consistentes, resistência à corrosão e conformidade com os padrões da indústria.

Esta combinação de linhas de produção profissionais e automatizadas, equipamentos mecânicos avançados, medidas rigorosas de controlo de qualidade e processos de galvanização de alta qualidade garante que entregamos produtos de estampagem metálica do mais alto padrão.