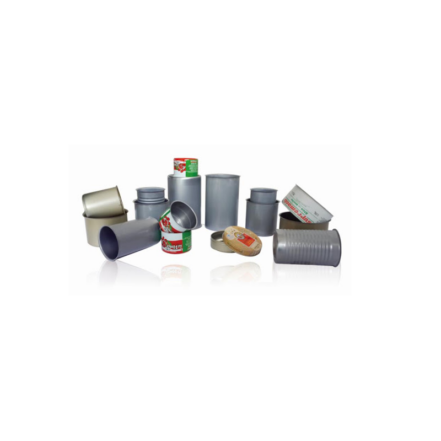

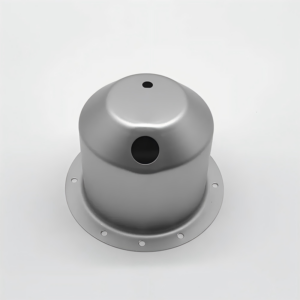

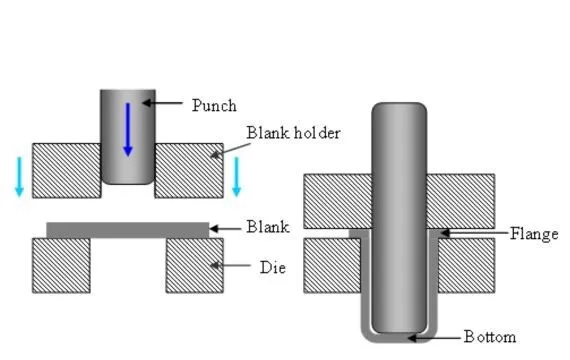

As latas de embutição profunda são recipientes metálicos de precisão, criados através de um processo de embutição profunda, no qual uma chapa metálica plana é progressivamente moldada numa lata oca e sem costuras, esticando o material numa matriz. Feitas de materiais como aço inoxidável, alumínio e latão, estas latas são valorizadas pela sua durabilidade, resistência à corrosão e capacidade de manter a integridade estrutural em condições extremas. As latas de embutição profunda encontram aplicações generalizadas em indústrias como a eletrónica, automóvel, médica e de bens de consumo, servindo como invólucros ou caixas de proteção para componentes sensíveis. A sua construção sem costuras e a possibilidade de personalização do tamanho, forma e espessura da parede tornam-nas ideais para aplicações que exigem dimensões precisas e padrões de alto desempenho.

Informação Básica

– Tratamento de Superfície: Galvanoplastia

Processo de Formação: Peças de Estampagem de Metal

Opções de Acabamento de Superfície: Revestimento de Níquel, Revestimento de Estanho, Revestimento de Zinco

Disponibilidade da Amostra: Disponível

Tolerância: ±0,001 mm

– Tamanho: Personalizável conforme o requisito

Aplicação: Industrial, Mobiliário, Automóvel, Motociclismo, etc.

Abordagem de Fabrico: Estampagem de Metal, Corte, Punção, Dobragem, Soldadura

Embalagem de Transporte: Saco OPP, Caixa ou Personalizado

Especificação: Personalizado

Origem: Xiamen, China

Vantagens do nosso produto

- Engenharia de Precisão

As nossas peças estampadas em metal são fabricadas com alta precisão, garantindo dimensões exatas e qualidade consistente para um desempenho ideal.

- Alta Durabilidade

Utilizando materiais robustos e técnicas avançadas de estampagem, as nossas peças apresentam uma resistência e durabilidade superiores, adequadas para aplicações exigentes.

- Produção Económica

A eficiência dos nossos processos de estampagem minimiza o desperdício de material e reduz os custos de produção, oferecendo soluções económicas para a fabricação em larga escala.

- Produção Rápida com Rápida Reversão

O nosso equipamento de ponta e os processos otimizados permitem ciclos de produção rápidos, cumprindo prazos apertados e exigências de grandes volumes.

- Aplicações Versáteis

As nossas peças estampadas em metal são versáteis e podem ser personalizadas para se adequar a uma ampla gama de indústrias, incluindo automóvel, aeroespacial e aplicações industriais.

- Qualidade Consistente

Medidas rigorosas de controlo de qualidade garantem que cada componente cumpre especificações exigentes e normas da indústria, proporcionando produtos fiáveis e consistentes.

- Tecnologia Avançada

Utilizamos tecnologia de ponta, como máquinas CNC e corte a laser, para obter cortes precisos e designs intrincados com elevada eficiência.

- Soluções Personalizáveis

Oferecemos opções flexíveis de personalização para atender a requisitos específicos de design e necessidades funcionais, proporcionando soluções à medida para diversos projetos.

- Opções de Tratamento de Superfície

Uma variedade de tratamentos de superfície, incluindo galvanização e oxidação, está disponível para melhorar o apelo estético e o desempenho das nossas peças estampadas em metal.

- Práticas Sustentáveis

Os nossos processos enfatizam a sustentabilidade ao reduzir o desperdício e otimizar a utilização de materiais, alinhando-se a práticas de fabrico ambientalmente responsáveis.