Visão Geral:

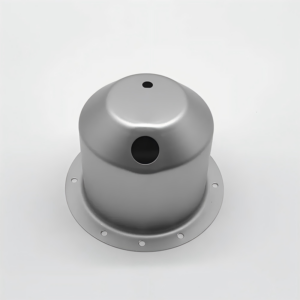

As buchas metálicas são componentes críticos concebidos para manter o alinhamento preciso, reduzir o atrito e minimizar o desgaste entre peças móveis. Comumente usadas como guias em operações de perfuração de precisão em metal, ajudam a garantir a exatidão operacional. Ao contrário dos rolamentos tradicionais, que dependem de elementos rolantes ou de esferas, as buchas apresentam um design simples e de peça única. Estes componentes podem ser personalizados com várias camadas de materiais condutores ou isolantes, ou lubrificação especializada, dependendo das necessidades específicas da aplicação.

Nas nossas instalações, especializamo-nos na produção de casquilhos metálicos personalizados, feitos à medida para satisfazer os requisitos exatos dos seus projetos. Com a nossa vasta experiência no fabrico de casquilhos de alta qualidade e precisão, oferecemos soluções que garantem um desempenho ideal, durabilidade e longevidade numa ampla gama de aplicações industriais.

Funcionalidades:

| Item | Detalhes |

| Local de Origem | Xiamen, China |

| Nome da Marca | OEM |

| Material | Alumínio, Cobre ou Personalizado a Pedido |

| Certificado | EU, ISO9001:2008, TS16949, ROHS |

| Tratamento de Superfície | Personalizado (conforme as necessidades) |

| Processo | Estampagem, Embutimento Profundo e Processamento Adicional |

| Amostra | Disponível/Aceitável |

| Funcionalidade | Suporte OEM |

| Tamanho | Personalizável |

| Cor | Personalizável |

Opções de Tratamento de Superfície para Buchas Metálicas Embutidas Profundamente:

-

Anodização

Este tratamento cria uma superfície robusta e resistente à corrosão, com maior dureza e uma estética melhorada, particularmente adequado para buchas de alumínio. Proporciona durabilidade a longo prazo e um acabamento de alta qualidade.

-

Eletrogalvanização

A galvanoplastia aplica uma fina camada de metais como zinco, níquel ou crómio à superfície, aumentando a resistência à corrosão, melhorando a condutividade elétrica e oferecendo uma proteção superior contra o desgaste.

-

Revestimento em Pó

A pintura a pó oferece um acabamento consistente, durável e visualmente apelativo, que proporciona excelente resistência a lascas, riscos e corrosão ambiental, ideal para aplicações que exigem uma proteção de superfície robusta.

-

Passivação

Um processo tipicamente usado para buchas de aço inoxidável, a passivação aumenta a resistência do material à corrosão através do tratamento químico da superfície, melhorando a durabilidade em ambientes agressivos.

-

Revestimento de Fosfato

O revestimento com fosfato oferece uma base de alta qualidade para a aderência da tinta, melhorando significativamente a resistência à corrosão, especialmente em condições de alta tensão ou exigentes.

-

Polimento

O polimento produz um acabamento liso e refletivo que melhora a aparência da bucha, reduzindo simultaneamente o atrito durante o funcionamento, contribuindo para uma maior eficiência e prolongamento da sua vida útil.

Processo de Produção de Buchas Metálicas Embutidas:

- Seleção de Materiais: A produção começa com a seleção cuidadosa do metal apropriado, como alumínio, cobre ou aço. A escolha depende dos atributos exigidos para o produto final, incluindo resistência, durabilidade e condutividade.

- Corte Inicial: Uma chapa metálica plana é primeiro cortada em discos ou peças brutas precisos, que servirão como forma inicial para o processo de embutição profunda.

- Estampagem Profunda: A chapa é colocada num molde e pressionada com um punção para iniciar a formação da peça. Através de uma série de etapas controladas, o metal é progressivamente puxado para dentro do molde, adquirindo a forma desejada - seja cilíndrica, com flange ou um design personalizado.

- Recozimento (se necessário): Para aliviar a tensão induzida durante a trefilagem, o metal é aquecido a uma temperatura específica e depois arrefecido gradualmente. Este processo melhora a ductilidade do metal, tornando-o mais flexível e menos propenso a fissuração.

- Aparagem: As bordas da bucha desenhada são aparadas para remover o excesso de material, garantindo um acabamento liso e dimensões precisas.

- Tratamento de Superfície: Dependendo da aplicação, a bucha é submetida a vários tratamentos, como revestimento, galvanização (por exemplo, zinco, níquel) ou polimento, para melhorar a durabilidade da superfície, a resistência à corrosão e o aspeto estético.

- Inspeção e Teste Finais: Cada casquilho é submetido a uma inspeção rigorosa para garantir que cumpre as normas dimensionais, de qualidade superficial e de desempenho. Os testes podem incluir medições de dureza, verificações visuais e avaliações funcionais para garantir que a peça funciona conforme o pretendido.

- Embalagem: Após passarem por todos os controlos de qualidade, as buchas são limpas, embaladas e preparadas para envio, garantindo uma entrega segura e eficiente.

Por que Escolher-nos?

Tecnologia de Ponta

Utilizamos tecnologia de ponta em prensas de estampagem multi-slide e four-slide para fabricar componentes metálicos de precisão, incluindo buchas, com exatidão e eficiência excecionais. Com a integração de software CAD/CAM avançado, técnicas de eletroerosão (EDM) e maquinação CNC, garantimos que cada produto é fabricado para atender às especificações exatas do cliente.

Capacidades Internas de Fabricação de Ferramentas e Moldes

As nossas capacidades internas de fabrico de ferramentas e moldes permitem-nos modificar rapidamente os designs sem incorrer em custos ou atrasos adicionais. Este nível de controlo sobre o processo de fabrico de ferramentas permite-nos oferecer prazos de entrega mais rápidos, mantendo resultados de alta qualidade de forma consistente.

Instalações Certificadas pela ISO

Operamos três instalações de produção totalmente equipadas, todas certificadas pelas normas ISO 9001, ISO 14001 e IATF 16949 (note que TS 16949 foi substituída por IATF 16949). Isto garante que cumprimos os mais elevados padrões globais de qualidade, sustentabilidade ambiental e conformidade com a indústria automóvel.

Fabrico Eficiente e Económico

Ao aproveitar técnicas avançadas de conformação, como a estampagem de quatro cursores, conseguimos alcançar uma produção de grande volume de forma eficiente, mantendo os custos competitivos e minimizando o desperdício de material.

Entrega Pontual e Personalização

O nosso robusto sistema MRP garante um alinhamento perfeito com os seus planos de produção, permitindo-nos oferecer entregas fiáveis e just-in-time. Também fornecemos etiquetas personalizadas e atualizações de stock em tempo real para satisfazer as suas necessidades operacionais específicas.