Manufacturing industries rely on various metal stamping techniques to produce precise and complex parts. Two commonly used methods are multi-slide stamping and progressive die stamping. While both techniques serve the purpose of shaping metal components efficiently, they have distinct differences in process, application, and advantages.

What is Multi-Slide Stamping?

Multi-slide stamping, also known as four-slide stamping, is a specialized technique that utilizes multiple moving slides to bend and form metal components. Unlike traditional stamping, which relies on a vertical press, multi-slide stamping uses horizontal tools that move independently to shape the material from multiple angles.

Key Features of Multi-Slide Stamping:

- Uses multiple slides for complex bends and intricate shapes.

- Allows high customization and design flexibility.

- Suitable for small to medium-sized parts.

- Reduces material waste by optimizing the forming process.

- Ideal for applications such as electrical contacts, spring clips, and connectors.

What is Progressive Die Stamping?

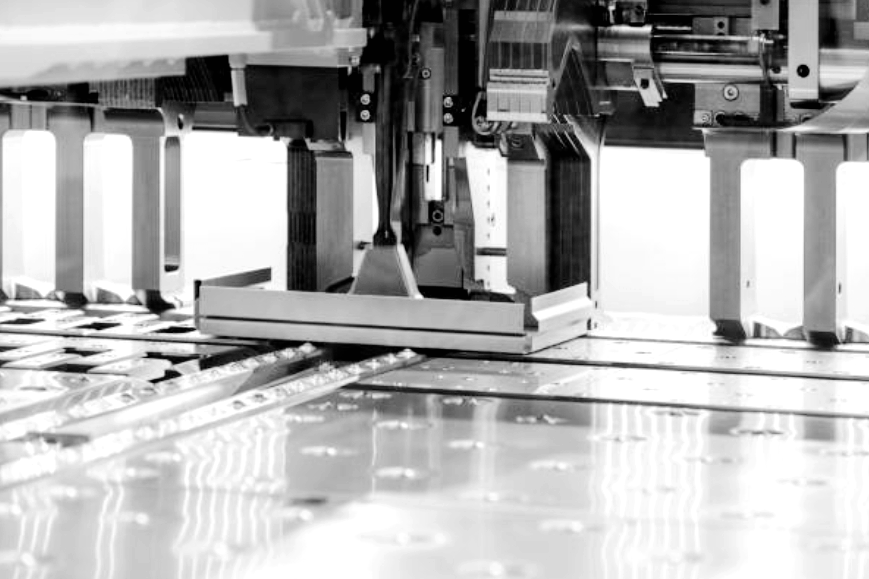

Progressive die stamping is a method that involves feeding a continuous metal strip through a series of stations within a die. Each station performs a specific operation, such as cutting, bending, or punching, until the final part is completed.

Key Features of Progressive Die Stamping:

- Uses a single die with multiple stations to perform sequential operations.

- Efficient for high-volume production runs.

- Ensures high repeatability and precision.

- Reduces labor costs due to automation.

- Commonly used for producing automotive parts, brackets, and enclosures.

Key Differences Between Multi-Slide and Progressive Die Stamping

| Funcionalidade | Multi-Slide Stamping | Estampagem Progressiva com Moldes |

|---|---|---|

| Motion Mechanism | Multiple slides moving independently | Continuous metal strip through sequential stations |

| Complexity | Suitable for intricate designs with multiple bends | Best for uniform, high-volume parts |

| Tooling Costs | Lower initial cost for custom tools | Higher due to complex dies |

| Production Volume | Small to medium batches | Ideal for mass production |

| Material Waste | Reduced due to precise forming | May generate more scrap |

| Applications | Electrical components, clips, connectors | Automotive, appliance, industrial parts |

Which Stamping Method Should You Choose?

Choosing between multi-slide and progressive die stamping depends on your project requirements. If your parts require complex bends and flexibility, multi-slide stamping is the better option. However, for high-volume, high-precision production, progressive die stamping offers efficiency and consistency.

Understanding the strengths of each method can help manufacturers select the best stamping process for their needs, ensuring cost-effectiveness and quality in production.

To learn more about our metal stamping processes or other services, contact us or request a quote.