The metal stamping industry is undergoing significant transformation, fueled by technological advancements, evolving industry needs, and rising global demand for precision-engineered components. This process, which converts metal sheets into a variety of shapes and sizes, is integral to a wide range of sectors, including automotive, aerospace, electronics, appliances, and more. At Plantmetal, we understand the driving forces behind these industry changes, and we are committed to offering high-quality, precise metal stamping parts that meet the needs of our customers. In this blog, we will explore the key trends and factors contributing to the continued growth and innovation within the metal stamping parts market.

Technological Advancements and Automation in Metal Stamping

The advancement of technology has been a critical factor in reshaping the metal stamping landscape. With the implementation of high-speed machinery, automation, and cutting-edge techniques, manufacturers can achieve faster production cycles, reduce human error, and enhance the precision of their stamped parts.

- High-Speed Stamping Presses: The integration of high-speed presses allows manufacturers to produce stamped components at a much faster rate, increasing overall production efficiency while maintaining accuracy.

- Servo-Drive Technology: The application of servo-driven systems provides precise control over the stamping process, ensuring flexibility and consistency in part production.

- Automated Coil Feed Systems: These systems automate material feeding, significantly improving production efficiency and reducing the chances of material handling errors.

- Computer Numerical Control (CNC): CNC machining plays a crucial role in controlling the stamping operations, offering enhanced precision and repeatability.

- Progressive Die Stamping: This method, which involves multiple operations performed in a single pass, streamlines the stamping process and reduces material waste.

- Real-Time Monitoring Systems: The integration of sensors and advanced monitoring systems ensures continuous quality control throughout the stamping process, allowing for real-time adjustments to maintain optimal performance.

- Quick Die Change (QDC) Systems: With the implementation of QDC systems, manufacturers can reduce downtime between production runs, maximizing machine uptime and overall output.

- Simulation Software: Virtual simulations allow manufacturers to optimize stamping processes before actual production begins, reducing costs and enhancing part quality.

- Robotics and Artificial Intelligence: Robots are increasingly used for material handling and secondary operations, while AI is utilized for predictive maintenance, quality control, and process optimization.

These technological advancements allow manufacturers like Plantmetal to stay competitive by improving efficiency, reducing costs, and increasing the quality of the metal stamping components we produce.

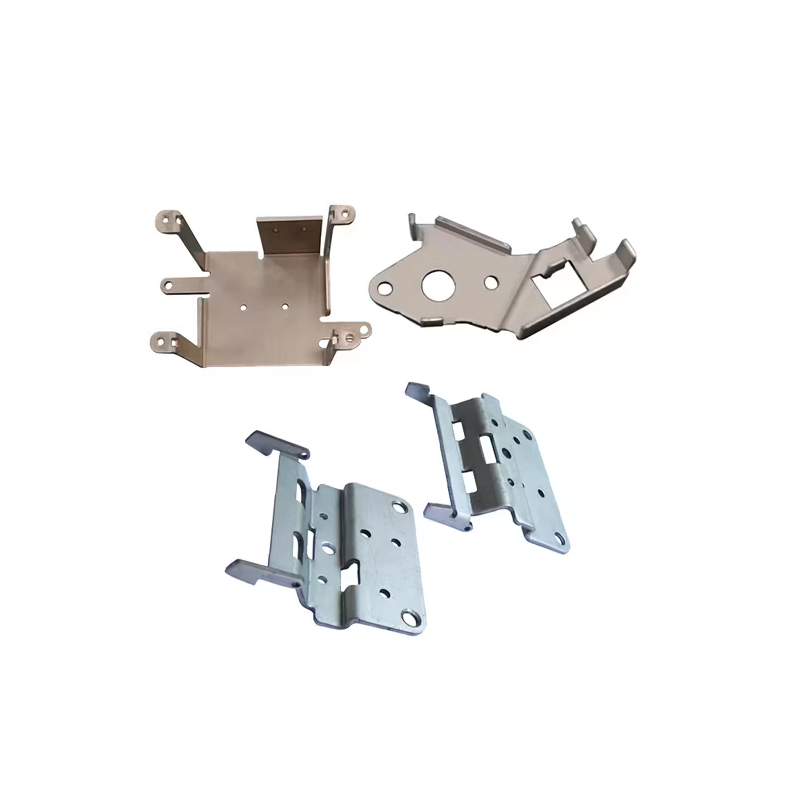

The Role of Lightweight Metal Stamping Parts in the Automotive Industry

As the automotive industry seeks to enhance fuel efficiency and reduce environmental impact, the demand for lightweight materials has surged. Metal stamping is playing a vital role in meeting these demands, offering the ability to produce parts that are both lightweight and durable.

By using materials like high-strength steel, aluminum, and advanced alloys, manufacturers can produce metal stamping parts that contribute to the creation of more fuel-efficient vehicles. These lightweight components help automotive manufacturers meet strict fuel economy regulations while still maintaining the durability and safety standards that are essential in the automotive sector.

At Plantmetal, we specialize in producing lightweight stamped components that are tailored to meet the unique needs of the automotive industry. Our precise stamping processes ensure that every part meets stringent performance standards, making us a trusted partner for automotive manufacturers worldwide.

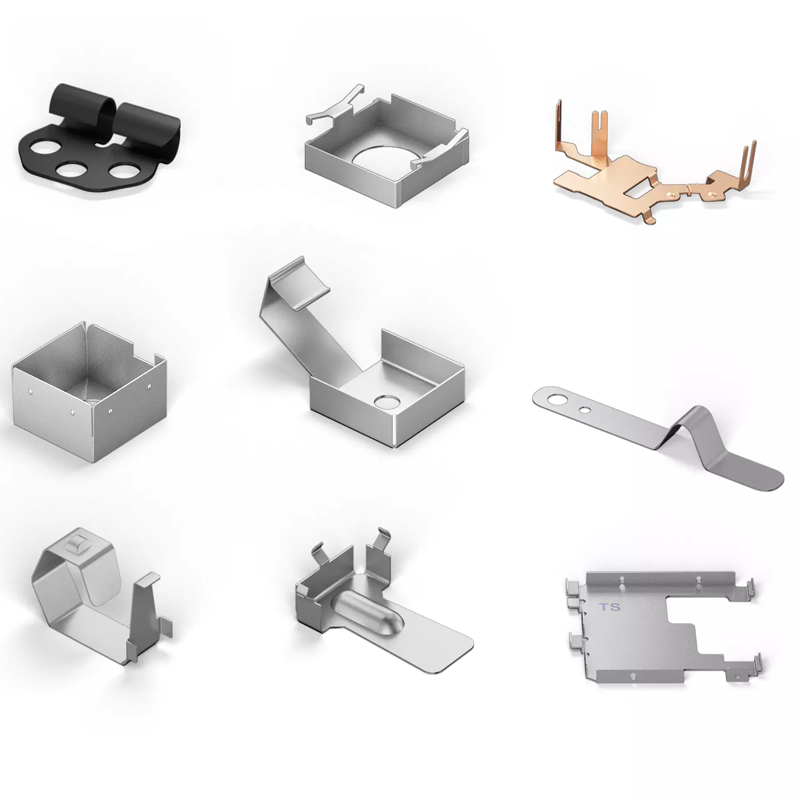

Customization and Complex Designs in Metal Stamping

One of the main advantages of metal stamping is its versatility in producing complex and customized parts. The ability to create parts with intricate geometries, tight tolerances, and customized shapes has made metal stamping a preferred choice in industries such as aerospace, electronics, and consumer goods.

Key aspects of customization in metal stamping include:

- Material Selection: Manufacturers have the flexibility to choose from a wide range of materials, such as steel, aluminum, brass, and alloys, to meet specific requirements.

- Custom Tooling: Custom dies and molds are used to produce unique shapes and designs that can meet the specific needs of different applications.

- Part Complexity: Metal stamping allows for the production of complex geometries that would be difficult or costly to achieve with other manufacturing processes.

- Tolerance Control: The ability to control tolerances with high precision ensures that each part meets exact specifications.

- Multi-Step Stamping: Multi-step stamping operations allow manufacturers to produce more intricate designs in a single process, reducing material waste and cost.

- Surface Finishing Options: Stamped parts can be treated with various surface finishes, including coating, plating, and polishing, to enhance aesthetics, improve corrosion resistance, and increase the part’s lifespan.

At Plantmetal, we offer a wide range of customized metal stamping parts designed to meet the specific needs of our clients. Our advanced technology and expertise allow us to create complex components that are both functional and aesthetically pleasing.

Rising Aerospace and Defense Expenditures

The aerospace and defense sectors continue to experience significant growth, driven by increasing military budgets and the development of next-generation aircraft. As a result, there is a rising demand for precision-engineered components capable of meeting stringent quality standards and performance requirements.

Metal stamping plays a key role in producing these high-precision parts, offering manufacturers the ability to create components with tight tolerances that are essential for aerospace and defense applications. These industries require parts that can withstand harsh environments and provide long-lasting durability, which is why metal stamping is a preferred manufacturing method for these sectors.

At Plantmetal, we have the experience and technology to produce aerospace and defense metal stamping parts that meet the highest standards of quality and performance. Our parts are designed to withstand extreme conditions, ensuring that they perform reliably in critical applications.

Sustainability Initiatives in the Metal Stamping Industry

Environmental sustainability is a growing concern in the manufacturing sector, and the metal stamping industry is no exception. Manufacturers are increasingly adopting sustainable practices to minimize their environmental impact. These initiatives include:

- Material Recycling: Recycling metal materials helps reduce waste and conserve resources, ensuring that manufacturing processes are more environmentally friendly.

- Energy-Efficient Manufacturing: Implementing energy-efficient technologies reduces energy consumption and the overall carbon footprint of production processes.

- Waste Minimization: Manufacturers are adopting methods to reduce waste, such as optimizing stamping operations and improving material yield.

At Plantmetal, we are committed to sustainability and continuously seek ways to improve our environmental impact. Our processes are designed to be energy-efficient, and we actively recycle materials whenever possible to reduce waste and promote sustainability.

Global Market Expansion and Regional Dynamics

As the global metal stamping market continues to expand, manufacturers are increasingly focusing on geographic diversification. Emerging economies present new opportunities for growth, driven by industrialization and infrastructure development. Tailoring products to meet the unique demands of these regional markets will be essential for sustaining growth in the metal stamping industry.

Plantmetal is actively pursuing opportunities in emerging markets, offering high-quality, customized metal stamping parts that meet the specific needs of local industries. By understanding regional dynamics, we are able to offer tailored solutions that support our customers’ goals, regardless of their location.

Strengthening Supply Chain Resilience

In response to global disruptions, manufacturers are increasingly prioritizing supply chain resilience. Strategies such as supplier diversification and localizing manufacturing processes are being employed to ensure that production remains uninterrupted.

At Plantmetal, we have adopted robust supply chain strategies to ensure that we can continue to provide high-quality metal stamping parts to our customers, no matter the external challenges. We are committed to maintaining a reliable supply of parts to meet global demand.

Conclusion

The metal stamping industry is evolving rapidly, driven by technological advancements, rising demand for lightweight materials, and increasing customization. As industries continue to innovate, manufacturers must embrace these changes to remain competitive. At Plantmetal, we are dedicated to staying ahead of the curve by investing in advanced technologies and continuously improving our processes. By offering high-quality, customizable metal stamping parts, we ensure that our clients receive solutions that meet the ever-changing demands of the global market. If you are looking for precision-engineered metal stamping parts, contact us today to learn how we can support your manufacturing needs.