Specifications

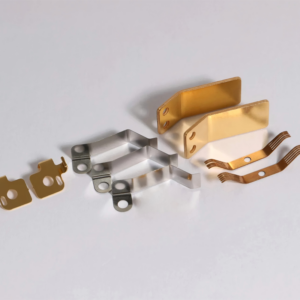

Surface Treatments: Galvanized, nickel plated, black oxide, dacromet, chrome-plated, nylok, white washing, phosphate, gold plated, anti-corrosion coating, etc.

Sample Time: 7-12 days

Lead Time: 15-25 days

Payment Terms: T/T, L/C with 30% deposit, balance due before shipping

Packaging: Carton and pallet, customizable as per requirements

Delivery Methods: By sea or express

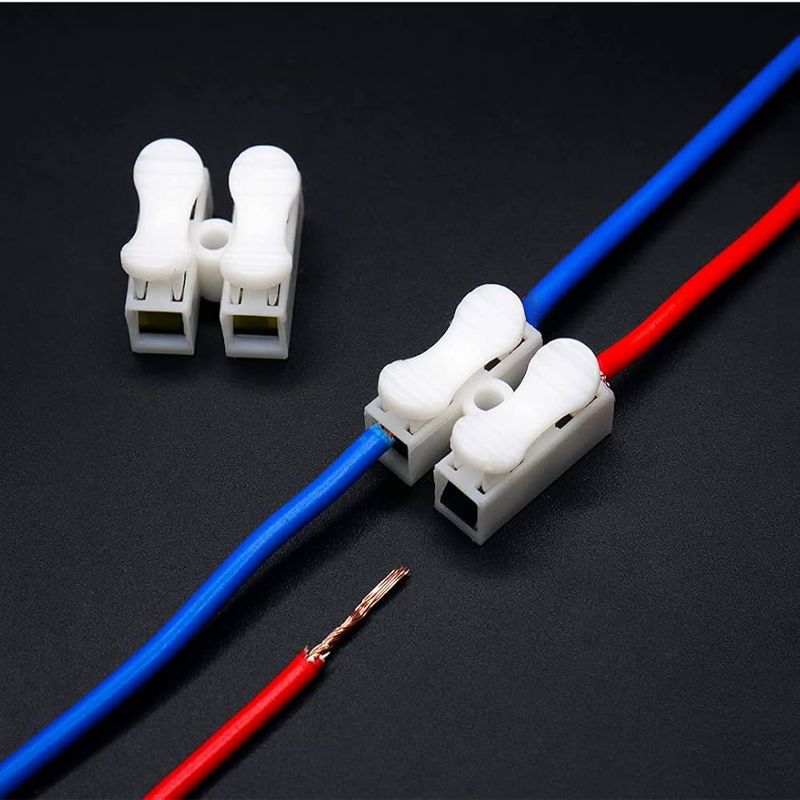

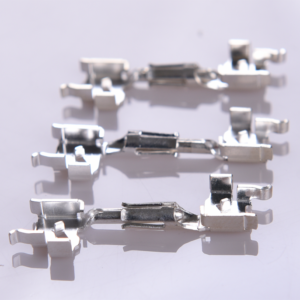

Customization Services for Metal Stamping Parts

– Design and Engineering: We provide extensive design and engineering services to customize metal stamping parts according to your exact specifications. Our team leverages cutting-edge CAD software and technical knowledge to create precise designs that align with your operational requirements.

– Material Selection: Select from a diverse selection of premium metals and alloys tailored for various applications. We guarantee that the materials chosen meet your performance and durability standards.

– Prototyping: We provide prototyping services to validate designs and functionality before full-scale production. This step ensures that the final product meets all specifications and quality standards.

– Tooling and Die Creation: Our precision tooling and die creation process ensures accurate and consistent part production. We use advanced machinery to fabricate tools that enhance production efficiency.

– Production: Utilizing state-of-the-art metal stamping technology, we produce parts with high precision and consistency. Our facilities are equipped to handle both small and large production runs.

– Quality Control: Each part undergoes rigorous quality control checks to ensure it meets the highest standards. We perform dimensional inspections, functionality tests, and material evaluations to guarantee reliability.

– Finishing and Surface Treatment: We offer a range of finishing options, including electroplating and polishing, to enhance the appearance and performance of your parts.

– Packaging and Delivery: Customized packaging solutions ensure that your parts are securely transported and delivered on time. We coordinate logistics to meet your scheduling needs.

– After-Sales Support: Our commitment extends beyond delivery. We provide ongoing support to address any issues and ensure customer satisfaction with our products.

Advantages of Our Metal Stamping Parts

- Versatile Applications

– Our metal stamping parts are versatile and can be customized to fit a wide range of industries including automotive, aerospace, and industrial applications.

- Consistent Quality

– Rigorous quality control measures ensure that every part meets stringent specifications and industry standards, delivering reliable and consistent products.

- Advanced Technology

– We employ cutting-edge technology, such as CNC machines and laser cutting, to achieve precise cuts and intricate designs with high efficiency.